Evolution of mankind :: A fantastic tour in Science City #Episode-10

The Traditional Iron & Zinc Work in India

Iron extraction

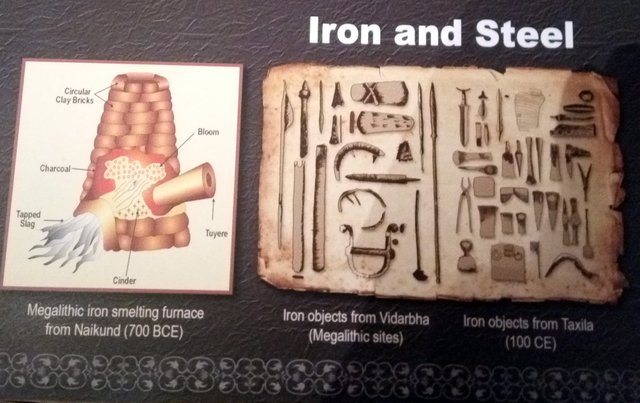

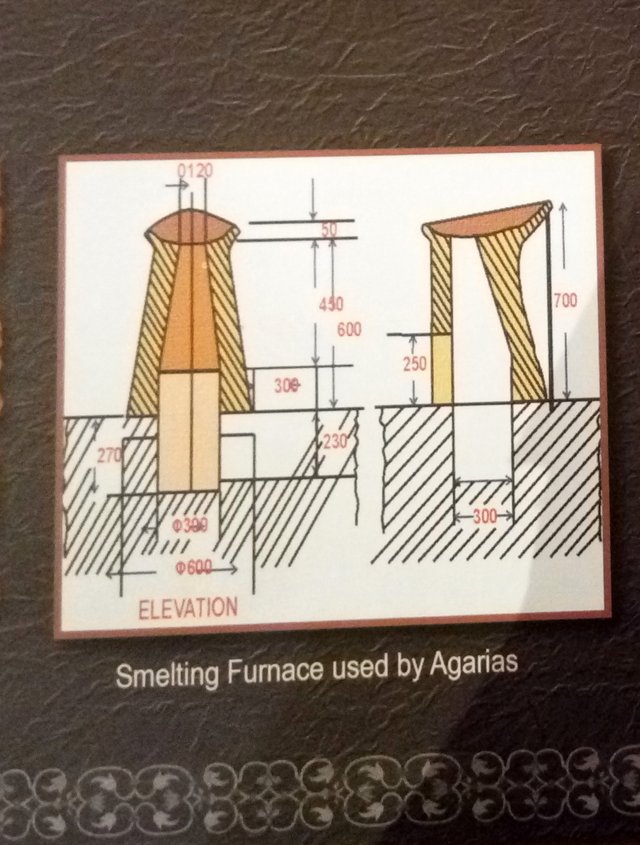

Iron occupies a special place in the early Pyrotechnology. With the evolution of metallurgical skills iron became a forceful agent of socio-economic change. In India iron metallurgy has undergone a process of evolution leading to the production of marvellous edifices like the Delhi Iron Pillar. Although there is very little data available by way of exact designs of ancient iron smelting furnaces, archeo-metallurgical studies by eminent scholars have helped in reconstruction of some of these furnaces. Based on these studies ancient iron furnaces have been broadly classified as bowl shape furnace, dome shape furnace and shaft furnace.

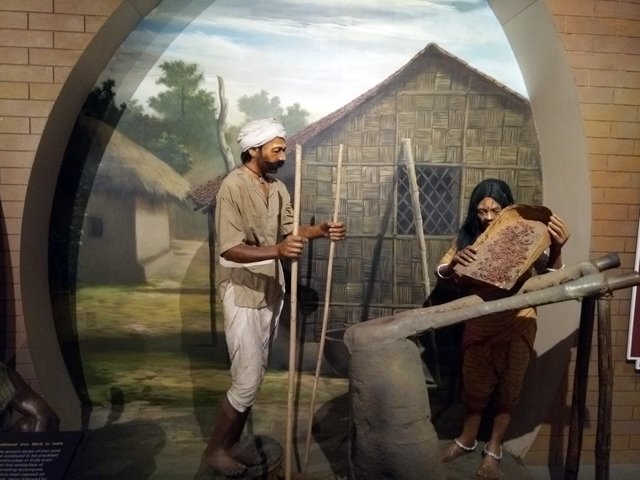

Woman pouring Iron ore into a furnace and man pumping air to furnace

A closer look - a woman is pouring Iron ore into a furnace

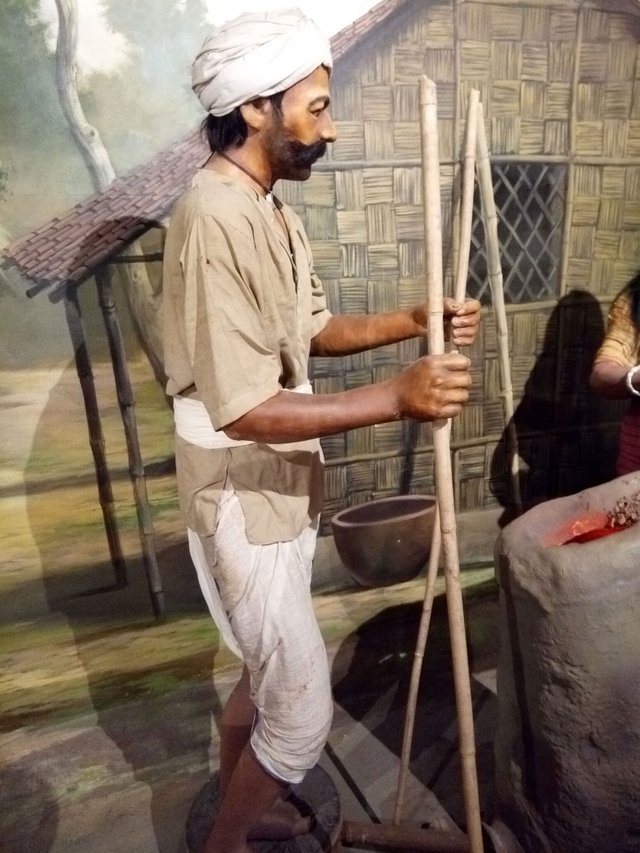

A closer look - a man is pumping air to furnace

Some of the ancient styles of Iron work in India have continued to be practiced by several communities in India even today. One can find similarities of ancient Indian smelting techniques, which perhaps have been passed on through generations, being followed by the Agaria community even today. Some of the documented techniques of the iron smelting being followed even in modern days by the tribal communities.

Iron extraction

After extraction Blacksmith hammering for making different iron tools

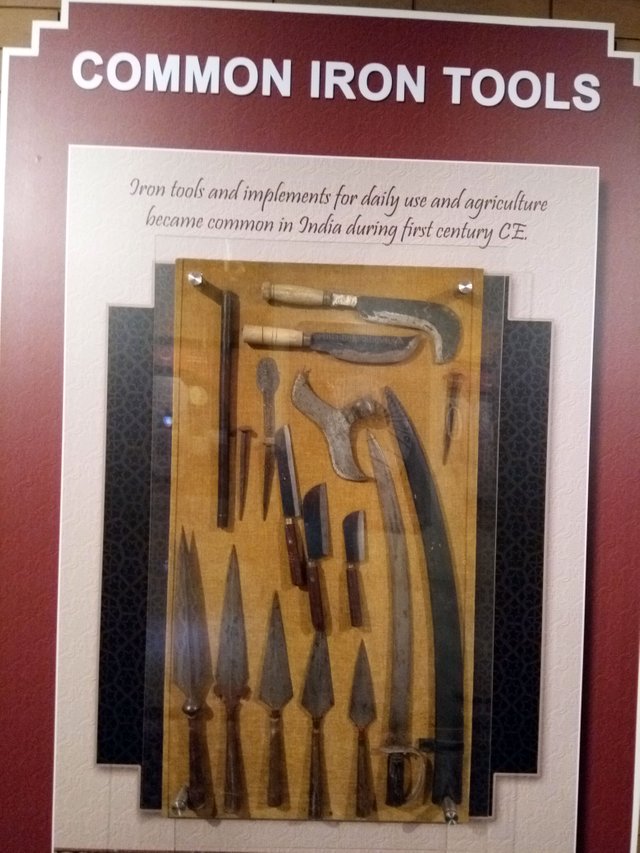

Different types of common Iron tools

Zinc Extraction in ancient India

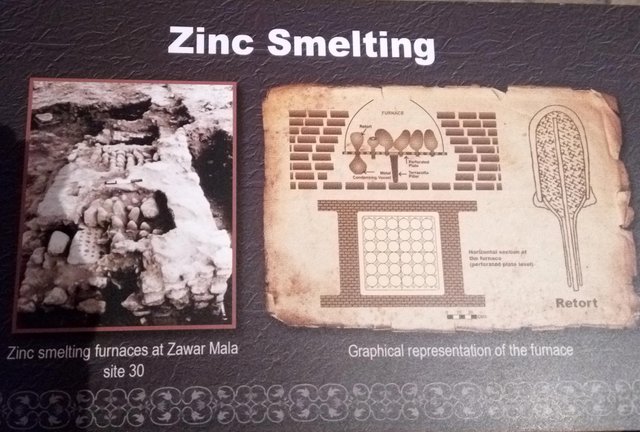

Ancient Indians were the first to produce matallic zinc on industrial scale. The earliest evidence of brass and zinc in the Indian subcontinent was almost textual. However, recent studies by archeometallurgists of zinc production at Zawar have revealed that the production of zinc by distillation process has a long history in India.

Extraction of zinc is difficult unlike other metals. Normally, metals like lead, copper, tin, etc. are smelted in as simple furnace and are collected as molten mass at the bottom. But, at such high temperature conditions, zinc, with its low boiling point (913 °C), vaporizes, gets re-oxidized and is lost in air. Therefore, zinc extraction requires a special process for smelting the ore and for retaining the vapour and condensing the same.

Zinc extraction

Retorts found at Zawar (Rajasthan) have the shape of the brinjal. It consists of a cylindrical portion and a tapering portion at one end. The zinc ore was roasted in air, to convert it to zinc oxide. Roasted mass together with reducing agents and fluxes such a charcoal, dolomite, salts etc. were ground and made into small balls using organic metarial as binder. They were filled in the cylindrical portion of the retorts. The conical clay condenser's head and neck were firmly fitted on to retort with clay, so as to leave no air gap. In order to create a clear route for zinc to escape from retort, into condenser head, a stick was used to push the condenser through the charge. On heating , the stick would char and drop out, leaving a central channel through the charge into the condenser through which zinc vapour could escape.

Zinc extraction

All source of info : Information Centre of Science City, Kolkata, India

[To Be Continued...]

Episode #01, Episode #02, Episode #03, Episode #04, Episode #05, Episode #06, Episode #07, Episode #08, Episode #09

follow me on steemit  AND resteem it

AND resteem it

>>Thanks to @elyaque for designing my badges :)<<

MY STATS

REPUTATION SCORE : 71.65 | TOTAL FOLLOWERS : 2880

TOTAL BLOG POSTS : 1651 | TOTAL LIKES : 90682

TOTAL EARNINGS : $29942.54 SBD

Buy photos from My Shutterstock Portfolio

This is amazing! Awesome job! Absolutely stunning delatis! 📷

many many thanks @ykdesign :D