The inkjet printer was printed with flexible graphene transistors.

Researchers have developed ink for printing flexible transistors and other semiconductor devices on industrial inkjet printers at room temperature and pressure. Scientists believe that due to the fact that such inks can be printed on different substrates, including fabrics, the technology can be used to create wearable electronics.

Virtually all of today's wearable devices, although they have flexible elements, are based on rigid electronics. But scientists are engaged in the development of technologies that will allow to create completely flexible, and due to this, more convenient devices. One of the most difficult tasks in this direction is the creation of flexible semiconductor components on which all modern electronics are based.

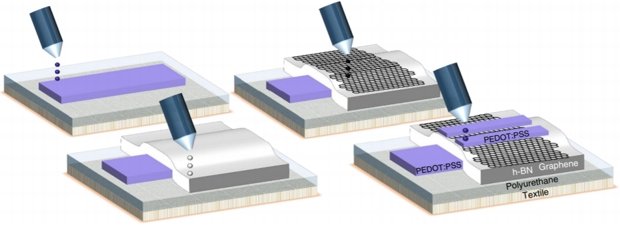

We developed a technology that allows us to create elements based on flexible heterojunctions using existing equipment. To do this, they developed a special ink composition for industrial inkjet printers. They consist of flakes of graphene and hexagonal boron nitride 15 and 24 layers thick, respectively. The average flake size is about 120 nanometers for graphene and 500 for boron nitride.

Source FET printout circuit

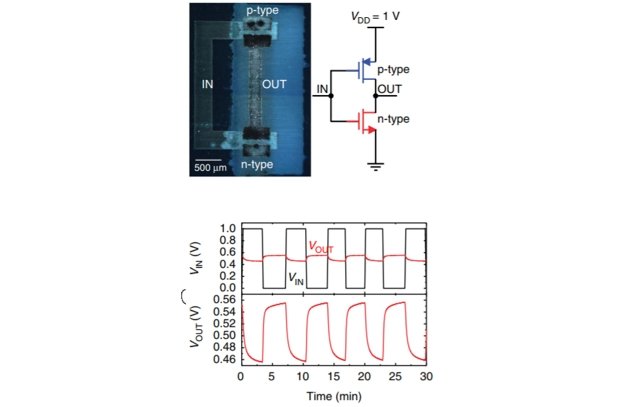

The researchers printed several basic semiconductor devices using such ink and an industrial inkjet printer. For example, they created a field-effect transistor in which electrodes were printed from silver, a channel of graphene ink, and a separating dielectric gate with ink from boron nitride. They also created a field effect transistor with electrodes made of conductive polymer PEDOT: PSS, an inverter that allows to convert AC to DC, and also a cell of volatile memory.

Source Printed current inverter

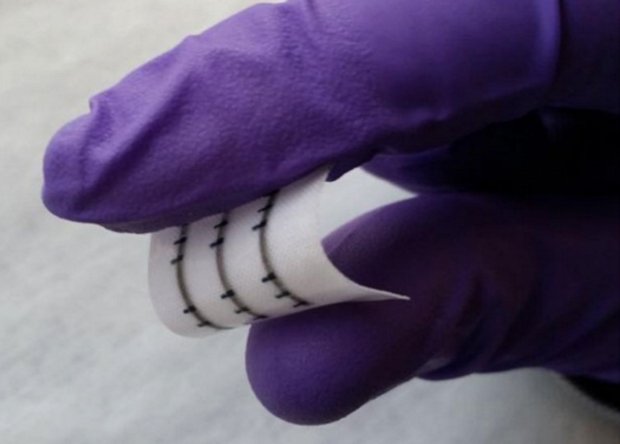

One of the important properties of the presented technology is that the researchers have shown the ability to print in this way not only on rigid substrates, but also on flexible polymers and even fabrics, for which it is necessary to apply a small layer of polymer. Scientists say that such devices can withstand stretching to 4 percent, as well as 20 dives into deionized water.

img credz: pixabay.com

Nice, you got a 12.0% @bubbleburst upgoat, thanks to @kuku12170

It consists of $0.35 vote and $0.12 curation

Want a boost? Minnowbooster's got your back!

The @OriginalWorks bot has determined this post by @kuku12170 to be original material and upvoted(1.5%) it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

The inkjet printer, once a revolutionary invention, has undergone significant advancements over the years. Today, it has evolved into a multifunctional marvel, catering to various printing needs, including photo printing, document printing, and even serving as a sticker label printer. The incorporation of sticker label printing capabilities has empowered businesses and individuals alike, enabling them to effortlessly create custom labels for products, packages, and organizational purposes. With its versatility and ease of use, the modern inkjet printer continues to be a vital tool in the realm of printing technology, revolutionizing the way we produce labels and various printed materials.