Rubbers - Their Properties and Usage Areas of Some Varieties

Hi Steemians, previously I shared an article about the rubber that article was mostly about rubber tree and technical chemical properties. Today I researched some more properties and uses of various rubber types. You can look at the previous rubber article from the link below.

Rubber Industry - The Crying Tree

Rubber is an elastic material obtained from exudations (natural rubber) or oil and natural gas (synthetic rubber) of particular tropical plants.

The main chemical components of the rubber are elastomers or elastic polymers, large-chain molecules, which can be extended at the high rate and can regain their original form. The first known elastomer is polyisoprene made from natural rubber. Natural rubber created in the living organism contains latex, suspended in milk fluid, called latex, circulating in the interior of most of the tropical and subtropical trees and Hevea brasiliensis, a high softwood tree mostly found in Brazil. Natural rubber was first scientifically defined in 1735 by Charles-Marie de La Condamine and François Fresneau. When the chemist Joseph Priestley found that he could use it to erase the pencil marks, he gave the rubber name in 1770. Its great commercial success has been following Charles Goodyear fabricated the vulcanization operation in 1839.

Some Types of Rubber and Their Usage Areas

While rubber manufacturers and producers make raw materials or semi-finished materials ready for use, they use raw materials and chemical compositions that are appropriate to the products of the rubber variety in the direction of the customers' wishes.

I will touch briefly on information about the types and properties of rubber in the list below.

1. Silicone Rubbers (MQ, VMQ, PVMQ): It is used between -60° C and 200 °C. It is resistant to 250 ° C intermittently. Its main use is crank felts. flexibility, air resistance and ozone resistance. It is not recommended in fuels, EP additives and applications where high mechanical properties are required.. Also, some of its application areas as follows,

- Sound and vibration damping in automotive drive shaft applications

- Shaft sealing rings

- Silicon O-rings

- Window and door gaskets

- Oven door gaskets

- Conductive profile silicone gaskets

- Cable and wire fittings

- Electrical safety cover

2. Styrene Butadiene Rubber (SBR): This type of rubber is the chemical material of choice today in many sectors. Butadiene and Styrene form a 75/25 copolymer. The solution is obtained by polymerisation and emulsion. Molecular weight between 250,000 and 800,000 is available. There is also no 27% oil expandability feature. If the structure ratio is irregular, it prevents crystallization.

3. Natural Rubber (NR): The protection, insulation and sealing properties are strong. Good vibration and noise is the absorber. The operating temperature range is -60 °C to 90 °C. It has similar properties to Styrene Butadiene (SBR) due to its environmental resistance. It can be used in areas that require high flexibility and mechanical properties. Some of the usage areas are impact supports, vibration isolators, gaskets and seals rollers, hoses, and pipes.

4. Nitrile Rubber (NR): It is resistant to abrasion, water, heat and gas permeability. It is a general purpose material resistant to oil and grease, which is recommended for most sealing applications. It is processed by offering various blends for fuels and industrial fluids. Resistance to gypsum-based brake oils and oils with EP additives is weak and is not recommended.

Nitrile rubber is typically used at ambient temperatures between -40 °C and 105 °C. It is resistant to 120 ° C in intermittent operation. It is preferred in terms of price/function balance.

Cork-filled nitrile mixture is used in gasket production. The strength properties of these materials are like standard nitrile. The presence of the cork also imparts compressibility (volume shrinkability). Corked nitrile finds use only in static applications. Usage areas are as follows,

- Automotive Industry: Carburetor and fuel pump diaphragms, fuel systems, hydraulic hoses

- Oil and Gas Industry: Rubber-metal bonded compounds, rubber connectors

5. Hydrogenated Nitrile Rubber (HNBR): It is produced from nitrile rubber NBR polymers. The properties of the materials and products prepared in this way must be high mechanical strength and more resistant to abrasion and durability. The environment resistance is between -40° C and 105° C such as Nitrile Rubber (NBR). Usage limit is 150 ºC.

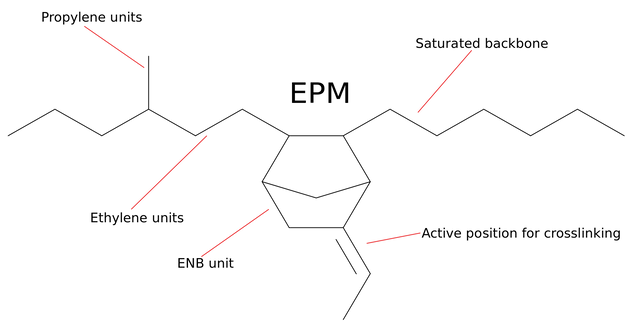

6. Ethylene-Propylene Rubber (EPM - EPDM): Polymerization of ethylene and propylene (EPM) began to be produced in 1963 for the first time. The reaction has a fully saturated structure since there is no double bond. This feature ensures that the rubber is resistant to ozone and oxygen. EPDM (Ethylene Propylene Diene Monomer) is obtained by introducing ethylene, propylene, as well as a third diene into the reaction. A large amount of filler creates low-cost mixtures due to the oil absorption capacity. Resistant to acids and bases, UV rays, ozone, aging, weather conditions and many chemicals. Some of the usage areas are as follows,

- HVAC (Heating, Ventilating, and Air Conditioning): Compressor shovels, mandrel forming drain tubes, pressure change hoses, panel seals and felts

- Automotive: Air evacuation and gaskets, wire and cable bundles, window separators, hydraulic braking systems, door-window-luggage gaskets

- Industry: Water system O-rings and hoses, pipe-gondola belts, electrical insulation

7. Polyacrylic Rubber (ACM): ACM is obtained by copolymerizing acrylic esters with monomers. Acrylic esters used; ethyl acrylate and/or butyl or octyl acrylate, ethyl methoxy or -ethyloxy acrylate. These copolymers are very resistant to oil, heat, aging, and ozone. The tensile properties of acrylic rubbers are not as good as NR and NBR. In particular, the new generation ACMs can operate up to 1000 hours at 160-170 ° C. But they show softening at high temperatures. ACM vulcanizates of animal, vegetable and mineral oils against swelling, excluding FKM, decreases with the rise of this property are more resistant to temperature than other rubbers. Resistance to chemicals is not very good either. Dry running is poor, low temperature and use in water are not suitable. More than 90% of ACM's production is used in the automotive industry. Usually, the crankshaft, the shaft seal and automatic transmissions and differentials in their next O-rings are used in valves, hoses, and oil. For many applications, fluoroelastomer (FKM) is preferred instead of abandoning other properties with the high price.

Working Temperature: + 160 °C / + 170 °C (1000 hours)

8. Fluorocarbon Rubber (FKM): It can be used between -40 °C and 150 °C. Resistance to phosphate ester fluids, glycol based brake fluids, water vapor, ozone and weather conditions is good and durable. Not suitable for use in fuels and petroleum-based oils.

9. Polytetrafluoroethylene (PTFE): It is a plastic material resistant to many chemicals used in the industry. There is stability in the application areas between -260° C and 260° C. The coefficient of friction is the lowest solid. It can be used as non-greasy mattress material without adhesion property. Some types are very good electrical insulators. Pure, glass fiber, carbon, graphite, bronze, molybdenum sulfide PTFE are used according to the application area.

10. Polyamide (PA): Widely known as "nylon". It can be used at temperatures between -20 °C and 90 °C. In special types, the usage limit can be increased up to 140 °C. The abrasion and wear properties are very good and it is a kind of raw material resistant to oils, fuels, esters, ketones.

11. Thermoplastic Polyurethane (TPU): Thermoplastic Polyurethane has good mechanical properties that allow it to be processed efficiently by injection molding. TPU's main advantages are; high resistance to abrasion, a wide range of temperature range flexibility, resistance to oils, greases and many solvents.

Physical Properties of Rubber Types

In the areas of our daily life, some tests are made to know the rubber-based materials that we use intensively and to know the chemical and physical properties of these materials. Appropriate rubber types are used according to the results of these tests. These are,

- Hardness

- Tensile Strength

- Tensile Modulus

- Elongation

- Resilience

- Compression Set

- Tear Resistance

- Abrasion Resistance

- Specific Gravity

If you want to look closely at the physical properties of rubbers, you can browse here

This is an amazing post man. Thanks for teaching me something. :)

excellent post friend continues like this

This post has received a 1.86 % upvote from @booster thanks to: @kedi.

Great Post

Wow! Thanks for a terrific post. Some I am really familiar with, some not so much. Thanks for such a detailed list.