The Science Behind Metallurgy (a brief explanation of the processes and their importance) part:1

(image care of Wikipedia )

Metallurgy is the study of materials and the science of extraction and production of metal.

metallurgy dates back to an estimated 7000 years ago during the chalcolithic era of human history when copper tools were being created in place of stone tools. since this time in human history great strides were made to improve on and discover better more reliable materials.

The ancient art of metallurgy has since than become a highly advanced practice involving some of the various techniques which I will be covering in this post. The most desired industrial processes typically involve shaft furnaces and fine materials fueled by natural gas heating, and in some rare cases microwave induction and arc furnaces.

In practical systems of production Iron oxides are used for their availability and ease of reduction, iron production makes up the majority of all metal production for it's practical and reliable properties...

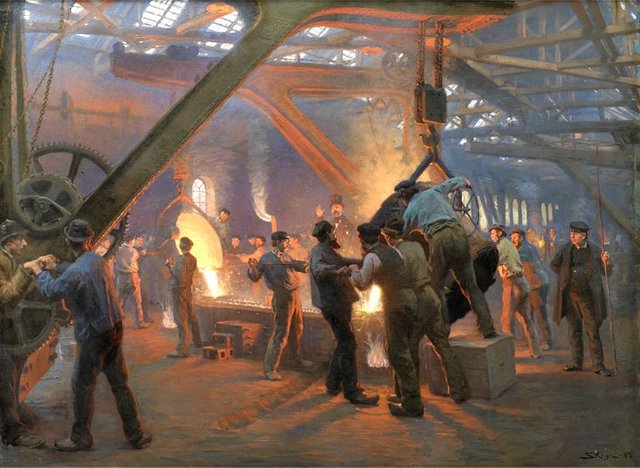

high temperature reactions involving molten phases are typically carried out under conditions of thermal equilibria (near or above melting point) in order to control mass transfer and create ease of material production (example: a foundry crucible pouring steel into a mold for railway tracks)

(From Fra Burmeister og Wain's Iron Foundry, Peder Severin Krøyer 1885. wikipedia)

In gas/solid phases mass transfer becomes more dominant as temperatures exceed the material capacity of the metal and often are assisted with a chemical equilibrium. (such as zinc oxide in the process of gold smelting for removal of slag and impurities from the metal.)

thus gas/solid phases are carried out in the highest possible temperatures quickly before the material interactions within the metal can damage the metal and leave impurities.

any transfer of materials must be done in it's liquid or gaseous states to prevent the medium (or material) from becoming compromised.

since most metals occur naturally in minerals chemical separation and thermal reduction become the desired extraction method.

in the case of oxides the main reduction agent is carbon monoxide. carbon dioxide is the key element in giving strength in steels and producing higher material purity

On a finishing note:

Every factor of this process permeates our way of life from our cars, our bicycles, our office towers and skyscrapers, even our computers. without metallurgy in the forefront of everything we do we would not have the quality of life we all enjoy and there would not likely be the luxuries that we have today. we are fortunate for the thousands of years of human effort which brought us such wonders. find out more about metallurgy by visiting your public libraries and finding great books on the subject...

Thank you everyone for your consideration...

Juno.

sources: https://en.wikipedia.org/wiki/Gold_extraction , https://en.wikipedia.org/wiki/Metallurgy , https://www.britannica.com/science/metallurgy

Book source: Fundamentals of metallurgy (woodhead publishing on behalf of the institute of materials, minerals and mining)

I couldn't do this because the heat can make me dizzy quickly

I am more concerned honestly about the lack of sleep I get cramming information then I am about the heat. just wait till I have to explain dendrites, isomers and crystalization.

Here's my favorite library so far, for any subject you care to name.

https://archive.org/search.php?query=metallurgy&and%5B%5D=mediatype%3A%22movies%22&and%5B%5D=mediatype%3A%22texts%22&and%5B%5D=mediatype%3A%22collection%22&page=3

upvoted! and with much joy and happiness. (i nearly fell over myself at the size of the collection)

It's the greatest resource I've ever seen, and that's not even counting The Wayback Machine on the main page. If I don't watch myself I can spend days there and never come up for air.

it's true... the knowledge contained in that resource page is massive!. really it's great! I cant thank you enough!