Different types of Mining Transportation

How Does Mining Transportation works?

In mining operation, amount of materials to be daily transported within and/or from the site is massive. Without the use of any kind of transportation, it is very hard or impossible to manually transport large quantity of raw materials from the mine site which is needed for the production. This problem gave way to the creation of Hauling System, which accelerated the production due to its efficiency in carrying load.

The first type of Mine Transportation system is the Truck Haulage.

Truck haulage is the most common form of materials transport in open pit mines. Trucks can be used to haul ore and waste out of the mine or they can be used to haul to an in-pit crusher where ore and/or waste can be crushed and then conveyed out of the mine. The trend has been towards larger and larger open pit trucks to match larger shovels and excavators. Trucks have the advantage over rail and conveyor systems where the haulage distance is relatively short and flexibility is needed.

There are two types of Truck Haulage machine.

- Rigid Body Trucks- It can travel with higher speeds and has a capacity of 30-150 tons.

- Articulated Trucks- It can be turn left or right sharply because of its pivot joint in its construction. It has a capacity of 25-40 tons.

The second type of Mine Transportation system is the Conveyor Haulage

A conveyor system consists of two or more pulleys with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward.

There are 3 types of Conveyor Haulage:

- Conventional Belt Conveyor-This is the most widely used type of conveyor. It can transport up to 1000 tons of ore per hour.

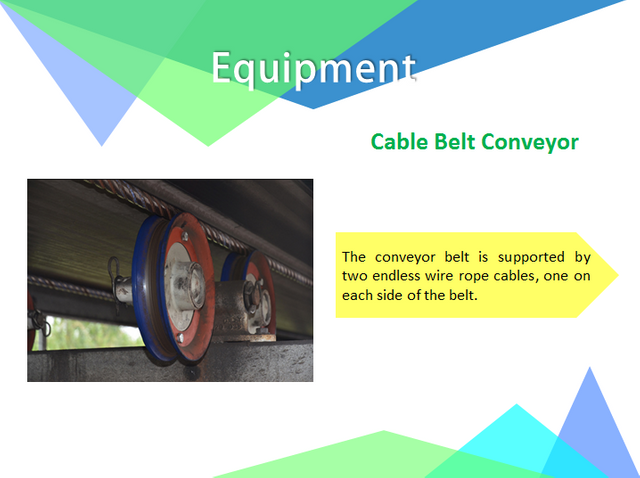

- Cable Belt Conveyor-Cable Belt is a unique conveyor design that is well suited for long distance conveyor applications where vertical and horizontal curves are required. The design differs to that of conventional conveyor designs. The conveyor belt is supported by two endless wire rope cables, one on each side of the belt, in lieu of idlers. The belt has almost no tension induced as it simply “goes along for the ride”.

- Pipe Conveyor - The Pipe Conveyor is an enclosed curve going transportation system for all kinds of bulk materials. At the loading and discharging points, the conveyor system is identical with open troughed conveyors.

The third type of Mine Transportation system is the Rail Haulage

Rail haulage is a means of transferring of passengers and goods on wheeled vehicles running on rails, also known as tracks. It is also commonly referred to as train transport. It is directionally guided by the tracks on which they run. Tracks usually consist of steel rails, installed on ties (sleepers) and ballast, on which the rolling stock, usually fitted with metal wheels, moves.

There are 2 types o Rail Haulage:

- Diesel Locomotive-It is powered by a diesel and was widely used in the mining before the conveyor and trucks became popular and took over the industry.

- Electric Locomotive- It is powered by an electric which also runs in the top of rail roads.

Article references:

https://en.wikipedia.org/wiki/Conveyor_belt

https://sites.google.com/site/mininginfosite/miner-s-toolbox/materials-handling

https://www.thyssenkrupp-industrial-solutions.com/en/products-and-services/mining-systems/belt-conveyors/

https://sites.google.com/site/mininginfosite/miner-s-toolbox/materials-handling/truck-haulage

http://www.e-mj.com/features/6161-opportunities-and-challenges-of-rail-haulage-systems-in-current-mining-operations.html#.WgJ5EmiCzIU

http://technology.infomine.com/reviews/Conveyors/welcome.asp?view=full

https://www.beumergroup.com/en/products/conveying-technology/pipe-conveyor

I have seen some of these while checking some nonmetallic mining areas in Mindanao. it looks so cool and expensive!