The Influence of Resin in The Paints

Hello dear steemian, good morning everybody, hopefully still health to read steemit post. in this opportuniy i wanna share you something about the paint

Protective Substance

Source : paintpad

Source : paintpad

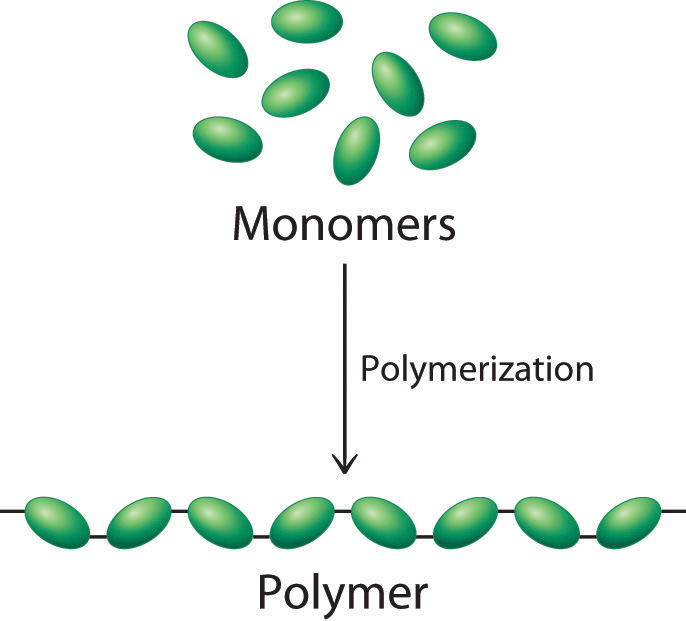

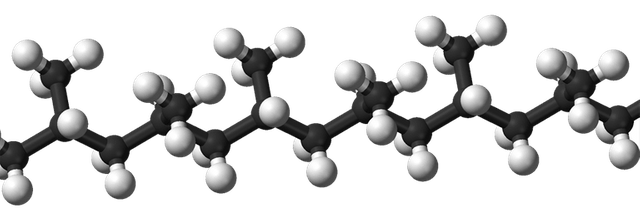

Discussing about the paint means we have discussed about polymers or related to organic chemistry, The paint is a liquid to coat a material surface with the aim for protection, decoration, and reinforcing of a material. Once the paint has dried up on the material surface, it forms a thin layer attached to the surface. Many ways to coat a surface with the paint, by wiping, spraying, dyeing etc.

The paint utilization is as a material to protect and give a color to a surface object by using pigment layer. Actually, the manufacturing of paint related to organic and polymer chemistry, the process includes colloid chemistry, electrochemistry and petrochemistry. The designing of chemical polymers for paints is composite which can achieve high functionality as a polymer chemistry application. The synthetic resins for paint manufacture is comprise several monomers to achieve various polymer characteristics, some commonly resin used like thermoplastic, thermosetting, and unsaturated resins. The main applications are synthetic resin, condensation polymerization and additional polymerization.

Main Ingredients of Paint

Source : socratic

Source : socratic

The main components of paint manufacturing are pigment and resin, the pigment is a chemical occur naturally or synthetic, the quality of a pigment determined by pigment strength against the medium. There are two kind of pigments was knows in paint manufacture that are interior and exterior pigments, the quality of the exterior pigment is judged from the fading time. Binders or resins are materials that are intended to attach the pigment to the surface of a medium. In the manufacturing of paints, the resin has several types namely, Acrylic, Alkyd, Vinyl, Nitro Cellulose, Polyester, Polyurethane, and Epoxy. Based on resin drying mechanism it divided into three stage.

Solvent Evaporation

Solvent evaporation is the process of drying (hardening) of the resin on the material surface, where the solids will stick flat on the entire surface of painted material, as long as the solvent hasn't evaporated, the resin wont be harden, to accelerate of drying process of paint, the resin should be heated, usually this resin has a high polymer, so the film will be formed without any chemical reaction, for example of this resin is Nitro Cellulose and Acrylic copolymer.

Air Contamination

The drying process of paint due to chemical reactions or components of resin was contaminated with the air, so the molecules of resin bind to each other, for example Alkyd, it has an unsaturated double bond of molecular structure and it is reactive to the air (oxygen). So that, in the certain room (high humidity) it should be added a dryer as catalyst.

Reaction Of Polymers

This reaction occurs to two resins that present in the paint mixture so it dries up, this reaction called as polymerization reaction. The polymerization reaction can occur due to both catalysts were heated or by ultraviolet radiation, the product of this reaction is a polymer blend which have a larger molecule and has a cross-link ( 3D bond) stronger. Although without catalyst, both resins highly reactive, so this pair of resins must be separated before using. for example of this resin is Epoxy.

General Paint Manufacturing

Generally, the manufacturing of paint is done through several processes including premixing, grinding, let-down, filtering, color matching, and packaging. The premixing stage is a mixing process of solid parts of the paint such as pigments and resins, then both substances are mixed into the solvent with addition some additive, it adapted to the wetting agent. At the grinding stage the pigment particles are smoothed by grinder to be more subtle, then the finishing process includes letdown, filtering, color matching to packaging. At this stage the paint is adjustable viscosity and addition of additives, the impurities filtered during stirring and adjusted based on the color, then the paint is ready to pack.

Conclusion

Conclusion

The main component of paint manufacture resin and pigment, pigment is a color substance, the quality of a paint is dependent on the resin, in certain types of paint the air can be as catalyst, because most paints containing alkyd resins are very reactive with oxygen, so in a humid room should be given a dryer. The paint also a protective, for example like a paint coating on the ships to protect the metal from corrosion.

Reference :

Support Scientist By Use #science tag or join @steemSTEM

Follow Me @jamhuery

Have you been asking the question, "How can I make money online?" If you want to know more information about this click on link

https://steemit.com/how/@kannouf/5vgqv8-have-you-been-asking-the-question-how-can-i-make-money-online

yes, i know how to make money online, i just did

i am a 111 voter of u