Kaporite Replacing Mercury (Hg) on Gold Processing, Kaporite More Environmentally

Aceh Science University

Aceh Science University

The use of mercury (mercury) in the gold processing industry is proven to pollute the environment. In response, researchers from the Faculty of Mathematics and Sciences Aceh University of Syiah Kuala (FMIPA Unsyiah) Banda Aceh found a breakthrough and new formula that is more economical and environmentally friendly.

"We offer the use of chloride acid mixed chlorine to separate gold from other materials. This chemical mixture is powered by up to 90% separating gold from a 100% potential content in one mill. This is because the capacity of the logs we offer is also greater, "

Said one of the research team FMIPA Unsyiah, Elly Sufriadi, to Serambi in Banda Aceh. Asked what the advantages of this method compared to using mercury and cyanide, Elly said swiftly,

"This way is more environmentally friendly. If the question of how it works would be more efficient, but if the price is relative, "

Said lecturer of majoring in this chemistry.

In this new formula, he explained that the ratio of the use of hydrochloric acid with chlorine is 3: 1. In the market, hydrochloric acid is priced at $40/35 kg and chlorine is sold $0.6 per unit. When compared to two-three ounces of mercury by separating the same amount of material, the money should be around $55, depending on the mercury price on the black market.

While the mercury power mixed into the material that has not been segregated between potentials or not, according to Elly, only about 40 percent. To that end, miners have to grind repeatedly to separate gold from other materials (rocks or clods of soil). Elly explained, gold mining activities in Aceh Jaya, Pidie, and West Aceh are very worrying. The death of thousands of fish showed mercury levels above the threshold.

Gold Purification

Aqua regia is formed by mixing a solution of nitric acid (HNO3) and hydrochloric acid (HCl) with a ratio of 1: 3. The mixing of these two types of solutions results in a redox event, which in turn will produce several new chemical compounds, as well as oxidation of chlorine ions into chlorine gas . The spontaneous reaction that occurs as follows:

HNO3 (l) + 3 HCl (l) ==>è NOCl (g) + Cl2 (g) + H2O (aq)The equationof chemical reaction above is just one of many other possible variants of results. From reaction (i) it is seen that mixing of HNO3 and HCl solutions produces chlorine gas, which is created from oxidation by NO3- ions on Cl- ion.

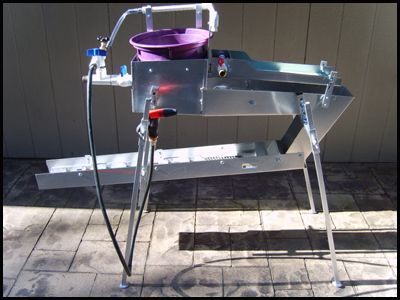

Preparation of Processing Equipment

Nitric acid which only reacts with some metals, the king's water reacts and dissolves almost all metals. Iron and nickel which is the basic material of stainless steel dissolves very slowly in HNO3, but reacts very quickly in the king's water. On this basis, the equipment used in the chlorination method should not be made of metal. The tools used must be made of heat-resistant glass (pyrex) or materials made of acid-resistant plastic.

- Tube / container where the reaction of chlorination is done. The container should be a kind of glass pyrex cooking pot, or beaker glass, or erlenmeyer. If using plastic, use a strong and transparent plastic container. Chlorinated base metals generally react very quickly, therefore use relatively large containers, especially when compared to the volume of metal to be purified.

- Stirring glass or plastic rods. A glass stirrer can be obtained at stores that sell chemicals and laboratory equipment. Mixer serves to form homogeny solution, and various other purposes.

Respiratory mask. - Use a good mask and have smooth pores. A good mask is a mask made of activated carbon, or a mask that uses a filter device from a zeolite material. The chlorination process produces NOCl gas and Cl2 gas which is a strong oxidizing agent. This gas is very dangerous if inhaled directly, and damage the metals that intersect with it. Therefore, in addition to avoiding direct inhalation, also keep metal equipment away from steam aqua regia. Basically the flue gas from the king's water can be neutralized using a strong reductor.

- The thick rubber gloves are able to protect most of the hands and arms.

- Laboratory shirt or warepack.

- Long stainless metal tweezers made of stainless steel. Tweezers are useful when metal smelting is done, or when taking small, harmful parts if it is in direct contact with the skin.

- The ash-free filter paper. Filter paper is used to separate the dissolved portion of the unsolved portion.

Media filter paper holder. Filter paper should be placed on a medium capable of passing fluid, but the medium must be acid and nitric acid. The type of media can be a pyrex glass funnel, or a plastic funnel, or a plastic flour sieve. - Topless made of glass or plastic. Topless is useful for metal shelter of soluble metal in aqua regia, or for the reduction process of gold chloride solution (tetrachloroaurate).

- Flat glass for drying white silver chloride powder.

- Burner is a tool that can produce temperatures up to 1600 C. This tool is useful for melting refined gold and silver metals. Burners generally use gas fuel. Be careful with burner use, make sure that you are using the correct usage instructions.

Chemicals

Purification of gold made using several types of chemicals.

- Concentrated nitric acid. This chemical compound has the chemical formula HNO3. In English, nitric acid is called by the name of Nitric Acid. The chlorination process should use raw nitric acid raw materials, namely nitric acid which has a concentration of 68%.

- Concentrated HCl / HCl technical. The HCl trade name is hydrochloric acid, or muriatic acid. Technical HCl usually has a concentration of 32% - 36%. The concentration of HCl may go down because of the nature of this solution, which is easily evaporated.

- Ferrous sulfate salt (FeSO4). This salt is easy to obtain in chemical stores. Fero sulfate serves to reduce gold ions to their metals.

- Sodium metabisulfite salt. Sodium metabisulfite has the chemical formula Na2S2O5. This compound also serves as a gold ion reduction.

- HN4Cl salt (ammonium chloride / ammonium chloride). This salt serves to detect the presence of platinum metal ion contamination in metal that has been dissolved in the Aqua regia .

- Urea, which functions for denitrification process.

- NaCl (salt kitchen). As with the gold purification process using nitric acid, one of a series of gold purification processes using chlorination also requires a solution of NaCl, which is used after the completion of the gold purification step. NaCl is used to separate the silver elements from other soluble climatic elements. Good NaCl should be salt that has a high enough NaCl content. Therefore, it is recommended that you use NaCl from industrial salt.

- NaOH or caustic soda. Fire soda is used in the substitution process of insoluble silver chloride to silver oxide.

- Borax is used in the process of smelting gold and silver metal. Borax functions as a flux during the course of the melting. The borax nature of the oxidizer makes the melt of gold or silver clean and protected from contamination of other metals that previously existed accompanying gold and silver. Usually the contaminant metals include copper and lead. Other types of chemical elements are metalloid types such as stibium, arsenic, and tellurium. Less contaminants can be easily oxidized by borax.

- Ca (OH) 2 or cooking chalk. This chemical compound serves as a neutralizing chemical fluid exposed to parts of our body, especially the fluid that splashed during the chemical process. Ca (OH) 2 or calcium hydroxide is also used to neutralize the pH of the wastewater, especially before the liquid metal sulfidation process is performed.

- Sodium sulphide or Na2 This chemical compound serves to neutralize liquid waste to be removed. The liquid wastes from the chlorination process contain metal ions, some of which are harmful to the environment. Waste disposal is urgently needed, in order for the waste to be removed to be safe against the environment.

Chlorination

The chlorination process is only optimally done if the gold metal to be purified has a high gold content, and a low silver content. Silver reacts with the king's water, producing 2 types of compounds, silver chloride / AgCl in the form of a white suspension, and a water-soluble dichloroquentate complex. The high silver content in the bullion to be purified can lead to passive metal against the king's water. The silver chloride layer can cover the metal surface of the chlorine gas attack, so the chlorination process goes slow, or stops completely. Therefore, the gold alloy to be purified should have a minimum initial gold content of 85%, and a silver content of no greater than 15%.

Source or Reference

Support Scientist By Use #science tag or join @steemSTEM

Follow Me @jamhuery

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by jamhuery from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, and someguy123. The goal is to help Steemit grow by supporting Minnows and creating a social network. Please find us in the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you like what we're doing please upvote this comment so we can continue to build the community account that's supporting all members.