How They Manufacture Hygiene Water ?? [My Scientific Work In Water Treatment]

Water Treatment Process

Water Treatment Process

Hello steemian, today i will share my scientific work in water treatment, how they produce the hygiene water for people necessity. Yesterday i posted an article about Hygiene Water, today i will describe a scientific work of water treatment.

Water used for necessity of human daily life and an important role for human survival, without water no one can be life. Health risks associated with water pollution generally can be classified in two factors, they are direct and indirect hazards. Direct hazards of human health may result from consuming polluted water or poor quality water,

Whereas indirect hazards can occur for example due consumption of fishery products where these products can accumulate harmful pollutants. Contamination of drinking water by viruses, pathogenic bacteria, other parasites, or chemical substances, may occur of raw water sources, or during streams of water process from centers to consumers. therefore the company has succeeded find and develop a process of water treatment technology feasible for daily necessity.

Main Process

PT. Ima Montaz Sejahtera is a manufacturing company engaged in producing bottled drinking water with various sizes as well as producing large-sized ice beams. The company was established on May 27, 1987. The source of water processed by this company comes from Peusangan river which first conducted the water purification process by PT. Pupuk Iskandar Muda. Water received from PT. Pupuk Iskandar Muda. The main raw material of drinking water production at PT. Ima Montaz Sejahtera uses water from Peusangan river then prosessed with pure water filter system (water separation process with mud), The water filtered and purified by PT. Pupuk Iskandar Muda then streamed to Water Intake of PT. Ima Montaz.

The water of Peusangan river pumped to water intake area, water intake facility is equipped with:

Water intake, is a blocked pool be form of a channel. Chanel of water intake is equipped with a screen bar to filter out rough objects floating above wiretaps, especially for river tapping.

Intake pond, is a pond with size of 27.9 x 7.6 m to accommodate water has been tapped from the source and used as raw materials. The water flow to Settling Basin with the pump.

Settling Basin, to precipitate graphite particles gradually and regulate the flow to transmit, the basin is divided five channels and alternately a channel is cleaning and mud was picked up.

Advance Process

Water treatment has various ways can be implemented to get pure water accordance of water criteria have been specified. The raw materials supplied from PT.PIM have been clean enough,so, the process we need only adsorbtion, filtration, disinfection.

Adsobstion

Activated carbon with granular media (Granular Activated Carbon) is a filtration process to remove organic materials, disinfection, and eliminate odors and flavors caused by organic compounds. In addition to exclude organic compounds, activated carbon also be used to exclude solute particles.

The adsorption process of activated carbon depends on surface area of the media used, its related of total area of the pores present in media. To streamline of adsorption process, adequate contact time is required between surface of media and treated water, then pollutants can be removed efficiently.

In water treatment plants, the processing activated carbon is done before ozonization process, because the process of activated carbon unit can not exclude pathogenic microorganisms such as viruses and bacteria. In addition, activated carbon also ineffective from excluding calcium (Ca) and magnesium (Mn) that cause hardness in water, flour and nitrate.

Filtration

The Water has undergone adsorbtion process out from bottom of carbon tank II and flowed to micro filter. The main purpose of micro filtration treatment is to remove contaminant particles with diameters greater than 0.5 microns. One useful of micro filtration is for environmental engineering to isolate coliform from samples of water under study. Micro filtration also used to remove airborne particulates that used as raw materials for ozone generators. MF membranes can be made from a variety of materials including cellulose acetate. The magnitude of membrane filter pores ranges from 0.1 micron to 0.45 micron.

The Next, water flows to accumulator tank leading 5 ton (E-8) and 10 ton (E-9) filtration. Ultra filtration uses membranes with pore size smaller than 0.1 microns and compressive ranging from 30 to 90 Psi. Ultra filtration can be used to exclude bacteria, viruses, colloids, and organic compounds have large molecules.

Disinfection

Water come out of ultra filtration (E-8 and E-9) flows toward ultraviolet (E-10) device. Disinfection process of drinking water treatment could use ultra violet (UV) rays. Electromagnetic waves with wavelengths between 200 nm - 300 nm (called UV-C) can kill bacteria, spores, and viruses. The most effective UV wavelength for killing bacteria is 265 nm.

The water passed through UV device then injected ozone on ejector and mixed through mixing ozone pump (E-11) and then flow to accumulator tank to hold water from ozone mixing more perfectly. The water in accumulator tank distribute to rinser and filter room. The water for rinser only pass through 5 micron of micro filter and this water used for washing bottle and bottle cap. The water filter will pass through 5 micron of micro filter toward ultraviolet tool for killing bacteria and neutralize of ozone. Furthermore, water is used to fill gallons, bottles and cups in a sterile room.

Ozonation

Ozone as a highly reactive commercial, in ozontion process instantly kill of microorganisms because can destroys cell walls (lysis). Ozonation does not produce dissolved solids and isn'tt affected by ammonium ions or the effect of pH in processing.

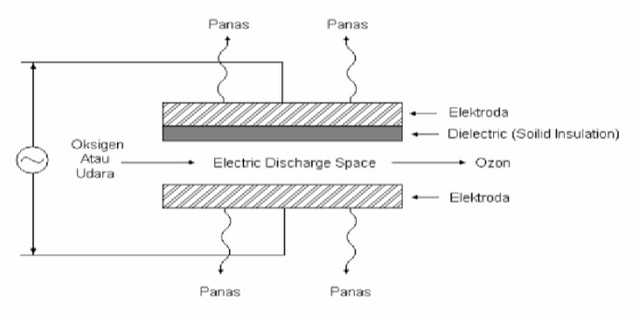

The discharge of electrical by passing oxygen to space between high-voltage electrical of alternating electrodes, its about 6,000 to 20,000 volts. The intermittent discharge between two electrodes will cause electrons to collide with oxygen molecule to form an ozone compound (O3). The selection of ozone formation using simple electrodes can be formulated as follows:

O2 + e 2 O + e (1) O + O2 + M O3 + (M) (2) O3 + O 2O2 (3) O3 + e O + O2 + e (4)

The equation of reaction both (1) and (2) are the reaction of ozone formation, but for the reaction (2) to continue of required third material M. The M material may be oxygen, nitrogen or tube wall. On other hand, if the reaction continues,the ozone has formed will decompose back through reactions (3) and (4).

This reaction is a reversible reaction, once ozone has formed decompose to oxygen. This reversible reaction occurs above 35°C. Therefore a cooling system is required in the ozone-producing system.

Disclaimer : This article source from my scientific work of PT.IMA Montaz Sejahtera

Me N Friend

Outside of Ima Montaz

More Reference :

Follow Me @jamhuery

nice o learn something today

Ozonation is more effective than chlorination

Hello there fellow environmental chemist! I love my job and I can tell that you do too with this very thought out and informative article. Thanks for walking us through all the steps. I just love learning lol 👏👏👏

Thanks for reading, i shared a lil experience what i got from water treatment, how they produce a hygiene water that free from gem

very good sir...

:)

thank for reading, i think u can study how machine work of this treatment. especially a machine in filler room

yes sir...

This is very helpful in Water Treatment Process ..

Great article! I'm a graduate student in Chemical Engineering, and I actually do research on developing better membranes for reverse osmosis (RO), which is another common method of purifying water. It's fascinating to see how many steps go into water purification. Thanks for sharing!

very impressive to hear you on a research, i love the research, lets join steemstem to share our science article. nice to meet you in chemical engineering mate

If I ever get around to publishing my work, I'll be sure to post it here for you to see. For now, here's an example of some similar research to what I'm doing. Glad to meet you too!

and me too, glad to meet you

Very impressive journal, we wait for your great research.

@jamhuery got you a $1.0 @minnowbooster upgoat, nice! (Image: pixabay.com)

Want a boost? Click here to read more!

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by jamhuery from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, and someguy123. The goal is to help Steemit grow by supporting Minnows and creating a social network. Please find us in the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you like what we're doing please upvote this comment so we can continue to build the community account that's supporting all members.