Flowsheet Engineering of Crystal Sugar Manufacture

Crystal of Glucose

Hello dear steemian, Surely everyone was not stranger with sugar, because it has become as staple food and basic needs. You often make sweet tea and coffee using the sugar, sugar is a material with white crystal-shaped. it is the product of glucose crystallization process, a liquid that makes up the sugar structure. Do you know how sugar produced ? I will explain you how sugar manufacture in some food industrial.

Image Source :Youtube

Image Source :Youtube

Sugar can be manufactured with any raw materials such as sugarcane, corn and others, but in this post I explain how sugar manufacture from corn raw materials. How does corn can be processed into sugar ? because the corn starch contain polysaccharide, The starch also composed of three fractions of polysaccharide such as amylose, amylopectin and protein. Starch also a complex polysaccharide composed of glucose that bridges each other naturally. Therefore, the corn can be processed glucose and sugar crystal.

How Does it Manufactured ?

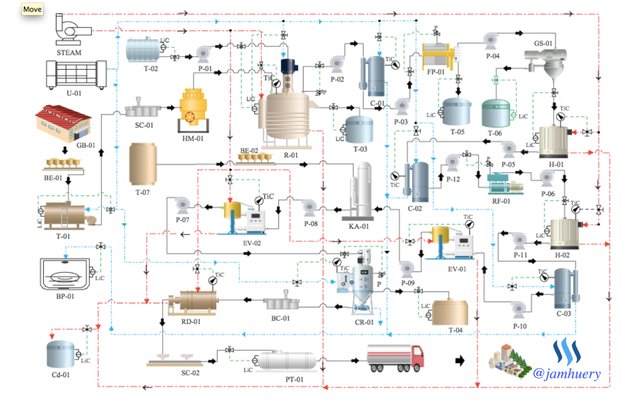

Well, to increase the knowledge of steemian community I will explain how sugar manufactured in the food industrial, look at this flowsheet. This flowsheet give an imagine how they convert the corn to the sugar crystal. All chemical products come from natural raw materials, they are processed on industrial scale require the auxiliary materials (chemical mixtures) to produce new products (result). Flowsheet bellow contain the Code each instrument, so everyone will knows how to read flowsheet. I will explain simple and clear explanation from flowsheet below.

GB-01 is a warehouse for storage of raw materials or corn. The corn from the shed is brought into Boiler Tank (T-01) by using Bucket Elevator (BE-01), Because the raw materials must be boiled to be soft, Then the raw material exported to the Hammer Mill (HM-01) using Screw Conveyor (SC-01). Once destroyed in a hammer mill, the raw material is fed into Main Reactor CSTR (R-01), the hydrochloric acid (HCl / T-02) also pumped into reactor as a catalyst, the catalyst only to speed up the reaction, then the outgoing catalyst accommodated in the Catalyst Storage Tank (T-03). In this reactor the glucose was formed then pumped into the Cooler (C-01) to get cooling process. Steam (red line) was injected into the reactor and exist as condensate and accommodated in a Condensate Storage Tank (Cd-01). Cooling water (blue line) go through Cooler and exist as water then accommodated in Water Reservoir (BP-01). After cooling process inside the Cooler, the glucose pumped through a filter press to filter fiber and residual HCl. Exist from Filter Press the glucose inserted into Gem Separator (GS-01) to separate the fat, Then the glucose pumped to the Heater (H-01) to evaporate residual water, then it passed Cooler-2 (C-02) for cooling process, exist from cooler it pumped to the Rotary Filter (RF-01) to remove the ash.

Crystallizer of Glucose

Source :My Thesys

Source :My Thesys

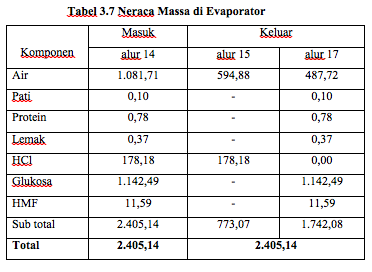

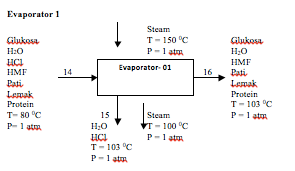

In order to clean the glucose from impurities it pumped to Heater-02 (H-o2) and also intend to evaporate water. Exist from H-02 it pumped back to the Cooler then forwarded into Evaporator-1 (EV-01) to evaporate water-borne substances with glucose. The water was evaporated here only 55% of incoming mass (mass In = 1,081.71 / Mass Out = 487.72), so it must be evaporate twice. Exist of EV-01 the glucose pumped to Column Adsorption (KA-01) to absorb HMF that contained in glucose. Then it pumped to Evaporator-2 (EV-02) to evaporate water. After water have been evaporated, the glucose exists into Crystallizer (CR-01), in this equipment the liquid glucose was converted to the crystal (sugar), then the crystal glucose transported into Rotary Drier (RD-01) using Bucket Elevator 2 (Be-02) for drying process. After crystal was dried it store in Close Storage Tank (PT-01) using Screw Conveyer 2 (SC-2). Why it should stored in the Closed Tank ? To avoid Ant Soldiers certainly.

The aqueous solution also affects the crystallization process, therefore the water content in ingredients must be evaporated as much as possible, after glucose passes through evaporator 1, there was still water remaining in the glucose, so the evaporation process should be proceed in evaporator2, the calculation of moisture content in glucose can be calculated based on the mass and energy balance.

Assumptive efficiency of Evaporator 01 = 55%

Total mass balance: F14 = F15 + F17

Glucose: F14 Glu = F13 Glu = 1.911.03kg / hr

HMF: F14 HMF = F13 MHF = 19,41 kg/hr

Starch: F14 starch = F13 starch = 0.10 kg/hour

Protein: F14 protein = F13 protein = 102.28 kg/hr

Fat: F14 fat = F13 fat = 0.64kg/hour

The mass balance in the groove 15 : Water: F15 Water = (F14Air) (0,55) = (1,081,71 kg/h) (0.55) = 594.88 kg/hHCl: F15HCl = F14HCl = 352.47 kg/hSo the water in the groove 17: Water F16 Water = F14 Water - F15 Water = 1,081,71 kg/hr- 594.88 kg hr = 487.72 kg/h

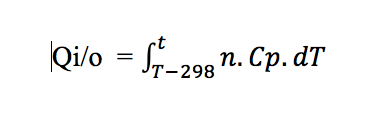

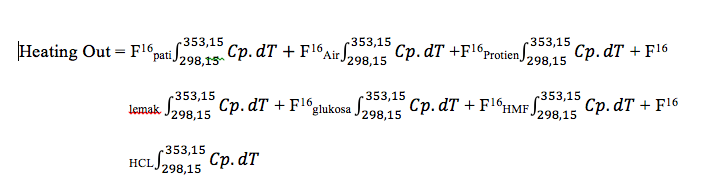

The Heat calculations for materials in liquid/gas phase with Formulation bellow

Energy Released by Steam

Source :My Thesis

Source :My Thesis

= (0,33 Kg/hr)( 200,4444 kJ/kg) + (359,54 Kg/hr) ( 32,1678 kJ/kg) +(1,51 Kg/hr)( 206,4582 kJ/kg) + (75,38 Kg/hr) (206,4582 kJ/kg) + (1.124,14 Kg/hr)( 182,86632 kJ/kg) + (11,42 Kg/hr)( 142,3500 kJ/kg)+ (0,00 Kg/hr)( 32,1678 kJ/kg) + (439,43Kg /hr) (13,3663 kJ/kg) + (167,50 Kg/hr) (74414,6947 kJ/kg) = 1.482.534.22 kJ/hr

Energy Released by Steam (Q) = Qo- Qi = 1.004.018.42 kJ/hrSuperheated steam at 1 atm, 1500C, H (1500C) = 2776,3 kJ/Kg (Reklaitis, 1983)

Saturated steam at 1 atm, 1000C, HV (1000C) = 2676 kJ/Kg (Reklaitis, 1983)

HL (1000C) = 419,064 kJ/Kg (Reklaitis, 1983)

λ = [H (150oC) - Hv (100oC)] + [Hv (100oC) - Hl (100oC)]

λ = [2776,3 - 2676,1] + [2676,1-419,04] λ = 2357,26 kJ/kg

Amount of steam required (m) = Q / λ = (1.004.018.42 kJ/hr) / (2357,26 kJ/kg)

= 425.92 Kg/hr

Conclusion

Conclusion

The corn (starch) can be processed into crystal glucose, the mechanism of processing through several stages, what I described above is only a summary, if an engineer wants to produce a new material, then they should know the nature of raw materials, processes of mechanism, and engineer the flowsheet and calculation of mass and energy balance. this flowsheet i designed my self when i was a student at Malikuussaleh University Aceh

Source :

Reactor CSTR / Crystallization

My Thesis / Ebook of Reklaitis, 1983

Support Scientist By Use #science tag or join @steemSTEM

Follow Me @jamhuery

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by jamhuery from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews/crimsonclad, and netuoso. The goal is to help Steemit grow by supporting Minnows and creating a social network. Please find us in the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

This post has received a 3.13 % upvote from @drotto thanks to: @banjo.

thank you for sharing knowledge.

I like your post. @jamhuery I have followed you