HOMEMADE CYCLING POWERMETER

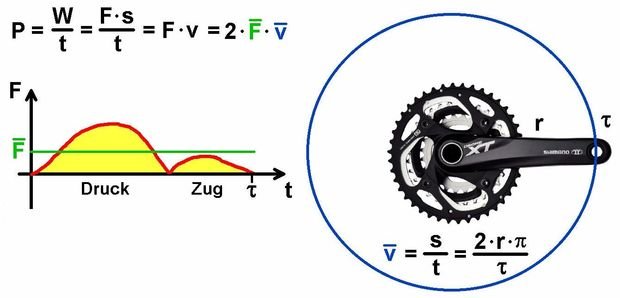

Step 1: The principle

To calculate the power, we have to determine the current force, which is spent by the foot on the pedal. For this purpose I clued four strain gauges (http://www.ebay.com/itm/5Pcs-Pressure-Sensor-Precision-BF350-3AA-BF350-350-Strain-Gauge-Resistance-/361278029289?hash=item541dd93de9:g:oOYAAOSwstxVOFv2) on the sides of my old crank. To get a Signal depending on the load I arranged them in a so called Wheatstone-Bridge.

During one full rotation I sum as many forces as possible and calculate the average. Combined with the average velocity (2 * Pi * crank-radius / rotation-time) I get the power P.

To know the proportionality between the force F and the output-voltage U I strained the crank with different masses and myself (a lot of mass ;-)). The rise of the line is in my case 292 Newton/Volt.

For the amplifier I took a LF353 with a gain of 330. With this Setup I get Output-voltages between 1 and 4 V. I decided to start at 1V to avoid a negative drift and late response. Therefore I have to determine the offset at the beginning of the measurement and subtract this offset from the following voltages.

Step 2: The setup

For the power-supply I use two lipo-battery packs (7.4V, 1200 mAh for the receiver and a smaller 600 mAh one for the transmitter).

To save space I use an arduino nano and the NRF24L01 are responsible for the communication. They work great and you can send as many values as you want. In my case I send the power (P) and the rounds per minute (rpm).

I also had to check, when a full rotation has accured. To avoid a sensor, which has to be mounted on the bike-frame, I decided to use the gyroscope MPU-6050. The accuracy is about +-3 degree per full rotation, which is satisfying.

Step 3: The completed crank and receiver

The challenge was to fix up all the components (power-supply, gyroscope, NRF24L01, amplifier, arduino) on one crankarm but I succeded. I fixed them with double-sided tape and cable ties.

To mount the receiver on the bar I use the clamp from a bicycle-lamb.

Step 4: The results

After calibration and programming I first tried my powermeter indoor on my training roller. I got reasonable values and therefore I went outside. Heureka, it works :-)

Finally I can say, that it's possible to build a simple and working powermeter for

2 x arduino nano ..... 10 USD

2 x NRF24L01 ......... 5 USD

16x2 LCD ................ 5 USD

4 x strain gauges ..... 10 USD

2 x Lipo battery pack ..... 15 USD

MPU-6050 ..................... 3 USD

electronic parts .............. 7 USD

less than 55 USD.

Here is the video:

To be continued... @itstudent

I am sorry for my no perfect English! I will try to write correctly!

If you liked this post write a comment indicating my nickname @itstudent, I will be very grateful! Thank you for attention! Do not forget to subscribe and put your up Vote!

This post has received a sweet gift of Dank Amps in the flavor of 1.92 % upvote from @lovejuice thanks to: @ideagenerator. Vote for Aggroed!