Concrete

Introduction:

- Concrete is a mixture of cement, aggregates (sand, gravel 3/15), water and sometimes other additives giving an easy-to-use liquid mix and pouring it into a mold to get the desired shape after it hardening in a precise time.

PH01: materiel d'ecrasement des matériuax.

PH02:Photo prise dans le laboratoire d'un échantillon de ciment.

PH03:Photo prise dans le laboratoire d'un échantillon des granultas 0/3.

Concrete is a material among the most used materials in the world (the second after water) commonly used in the construction world (houses, buildings, bridges, roads ... etc)

This material is characterized by its high resistance to compression (constitutive law), it can withstand compressive loads up to 1000 bar.

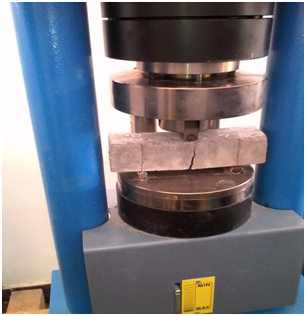

PH04: eprouvettre de béton 4416 soumise à l'essai de compression.

- On the other hand, its tensile strength and flexural strength is small compared to its compressive strength.

PH05: eprouvettre de béton 4416 soumise à l'essai de flexion.

- For this concrete is generally reinforced by steel in the construction to withstand all loads of the structure.

- To verify that the concrete used for a requested work is requested to carry out a compression test on a 16/32 cylindrical specimen (16cm diameter / 32 cm height) or cubic specimens or other forms.

PH06: eprouvettes de béton 4x4*16.

PH07: presse ou machine de l'essai de compression.

The concrete life after the setting of the cement is characterized by three important periods:

1- [0-28 days]: setting and hardening of the concrete between the liquid phase up to 90% of the concrete resistance is obtained in the 28th day.

2- [28-90 days]: 90% resistance at 28 days at 99% compressive strength at 90 days.

3- after 90 days: the compressive strength of the concrete increases but with very small values that can be neglected therefore, it can remain years to reach these 100% of resistance to the compression.En laboratoire pour contrôler la qualité de ce matériaux on peut pas attendre beaucoup de temps pour voir les 100% du matériau donc en 28 jours on peut écraser et voir le résultat qui va donner directement la résistance de béton à la compression.

After having the results in the laboratory, the construction engineer can intervene in time by changing the concrete formulation or any cause decreasing the quality of the concrete.

Other machines can measure the quality of already hardened concrete, for example the sclerometer as it is shown in the following photo:

PH08: photo prise d'un sclérométre au laboratoire.

NB: the texts have been written by me

if you like my job:

1- Subscribe.

2- Share the max.

3-Invite your friends.

Thank you for your attention.