INTRODUCTION TO PROGRAMMABLE LOGIC CONTROLLERS (PLCs) - Part 1

Hi Friends, after my Electronics Lectures two days ago, the lecturer mentioned of Programmable logic controllers as an example of an electronic/digital System controller, it cause my attention, so after my little research on the subject i felt to share my knowledge to my follows lovers of electronics and digital systems.

What is a Programmable Logic Controller?

A programmable logic controller (PLC), or programmable controller is an industrial digital computer which has been ruggedised and adapted for the control of manufacturing processes, such as assembly lines, or robotic devices, or any activity that requires high reliability control and ease of programming and process fault diagnosis. They were first developed in the automobile industry to provide flexible, ruggedised and easily programmable controllers to replace hard-wired relays, timers and sequencers. Since then they have been widely adopted as high-reliability automation controllers suitable for harsh environments

Basic Operation of a PLC

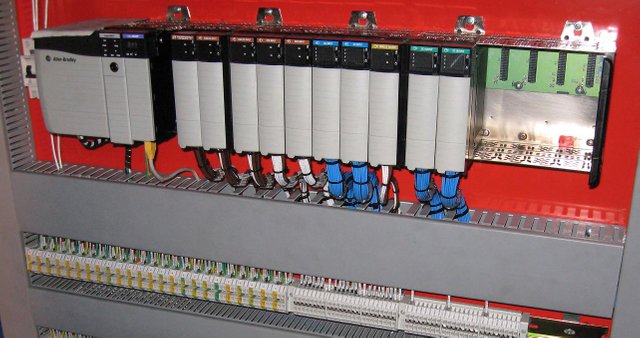

Some may wonder if a PLC is a single device one can handle just like a our cell phones, but no, its a set of an electronic/digital programmable setup meant to control the process machines and heavy devices.

How simple can process control be?

Consider a common household space heater.

The heater's components are enclosed inside one container, which makes system communications easy. Expanding on this concept is a household forced-air heater with a remote thermostat. Here the communication paths are just a few meters and a voltage control is typically utilized.

Think now beyond a small, relatively simple process-control system. What controls and configuration are necessary in a factory?

The resistance of long wires, EMI, and RFI make voltage-mode control impractical. Instead, a current loop is a simple, but elegant solution. In this design wire resistance is removed from the equation because Kirchhoff's law tells us that the current anywhere in the loop is equal to all other points in the loop. Because the loop impedance and bandwidth are low (a few hundred ohms and < 100Hz), EMI and RFI spurious pickup issues are minimized. A PLC system is useful for properly controlling such a factory system.

What are the Functions and Applications of PLCs ?

The functionality of the PLC has evolved over the years to include sequential relay control, motion control, process control, distributed control systems, and networking. The data handling, storage, processing power, and communication capabilities of some modern PLCs are approximately equivalent to desktop computers. PLC-like programming combined with remote I/O hardware, allow a general-purpose desktop computer to overlap some PLCs in certain applications. Desktop computer controllers have not been generally accepted in heavy industry because the desktop computers run on less stable operating systems than do PLCs, and because the desktop computer hardware is typically not designed to the same levels of tolerance to temperature, humidity, vibration, and longevity as the processors used in PLCs. Operating systems such as Windows do not lend themselves to deterministic logic execution, with the result that the controller may not always respond to changes of input status with the consistency in timing expected from PLCs. Desktop logic applications find use in less critical situations, such as laboratory automation and use in small facilities where the application is less demanding and critical, because they are generally much less expensive than PLCs

Friend I think We are cool for today, by next we see look at the complex functions of a PLCs, timers and counters, program codes of PLCs, etc. Have a nice day Friends.

References; Wikipedia,