Legumes: A comprehensive processing overview – Part 2

This is part 2 of a three-part series, the first part is in the link below.

Legumes: A comprehensive processing overview – Part 1

This second part will continue with the physical treatment processes that are used to deal with anti-nutritional factors present in legumes.

Extrusion

First, let’s describe what extrusion is. Extrusion combines both heat, mechanical stress, and short times to shape food materials into a specific configuration. Commonly the food material is lead into a heated barrel with a rotating screw. The screw forces the material through a die plate that is responsible for shaping the product. A clear upside to choose the extrusion process is the short residence times of the food material. Even if the material is subjected to higher temperatures the thermo-labile nutrients suffer minimal damage from the short-term heat exposure.

Extrusion achieves inactivation by physically deforming the proteins. This deformation of the secondary and tertiary structure of TIs is enough for their denaturation. The downside is that if the extruder achieves inactivation of the TIs by structure deformation than the nutritious proteins are also affected. This is translated into different functional properties such as increased solubility but decreased emulsifying activity. The extrusion process has both positive and negative effects on the functional properties of the final product. The usability, therefore, relies on the intended use of the product. If you would like to dissolve the product and use it in bread or protein-enriched beverages then extrusion is ideal. When you want more of an emulsifying property for making margarines, mayonnaise, or dressings then extrusion will make your product unusable.

Ultrafiltration

Instead of inactivating the TIs, ultrafiltration takes another route. It is able to remove the TIs while separating them into different fractions. This makes ultrafiltration a very mild processing technique. While ultrafiltration has not been used on many legumes yet it has been tested on chickpea protein concentrates. Sadly it did not have the intended effect as only a 9.47% reduction of TIs was achieved. More testing has to be done for ultrafiltration to be a useful technique to decrease ANF activity. Now it is more usable as a technique to investigate the types and sizes of ANFs in legume protein suspensions.

Ultrasound

This technique also has many unknowns regarding TI inactivation. It works by something called cavitation. Cavitation is the creation of gas bubbles rapidly followed by collapsing. These popping bubbles disturb the protein structure by breaking the disulfide bonds. These disulfide bonds keep together the tertiary protein structure, which makes this technique not affect the essential amino acids.

More studies are needed to judge whether this technique should have more use as a removal tool for TIs. Since it affects the proteins it will also affect the functional properties of legumes. It has been found that the structural changes in the proteins increase the solubility. Information about other functional properties is not available.

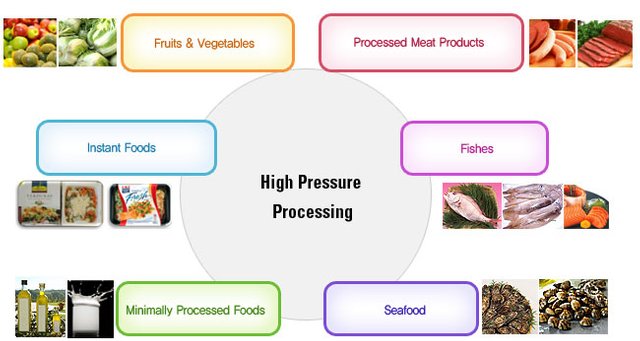

High Hydrostatic Pressure

The benefit of high hydrostatic pressure (HHP) processing is that it is nonthermal. HHP has a minimal effect on the covalent bonds of the molecules (the bonds that keep the building units of the proteins intact) but does have an effect on the other interactions between the proteins, i.e. hydrophobic and electrostatic interactions.

HHP is especially popular to use with a milder thermal process. Common combinations of HHP and temperature are 2500/50, 5500/19, 5500/65, and 5500/80 bar/°C. Remember that the air pressure at sea level is 1 bar, car tires around 2.2 bar. Imagine the intensity of 5500 bar!

The combination of HHP with 65 °C gave 76% reduction of TIs after 15 mins. Only using the thermal treatment of 65 °C gives a similar reduction, but only after 60 minutes. That’s a 45 min reduction of heating time.

While HHP is still an emerging, and therefore relatively expensive, technique, it is already proving valuable as a tool for improving the nutritional value of legumes.

Instant Controlled Pressure Drop

This technique also uses a high pressure combined with thermal treatment. It applies steam to the food product at high pressure over very short treatment times (< 3 mins). The pressures are significantly lower than in HPP, as they go up to 8 bar. However, the temperature can go up to 170 °C.

Instant controlled pressure drop proved very effective at inactivating TIs. One variant of TI was inactivated by 95.4%, 98.6%, and 98.3% respectively when applying 7 bar for 1, 3, and 6 minutes. Using 6 bar for 1 min even achieved 99.7% inactivation of TIs. The seeds that were tested became more porous, which increased the availability of some nutrients an decreased other ANFs such as phytic acid and lectin.

The short treatment times and effective TI inactivation show that instant controlled pressure drop could be an excellent alternative for ANF inactivation. It is still quite a new technique so more developed and research is needed to see if it works for the large variety of legumes and ANFs.

Radiation

While radiation might sound scary to some people out there, it is simply another variation of thermal treatment. For the food industry, infrared radiation (IR) is an interesting technique because the heat response is much faster than it is for standard thermal treatments. The inactivation method of IR is identical to standard thermal treatments, which was the interruption of intermolecular bonds leading to the destruction of the tertiary structure of proteins. The difference is the mode of transfer of the heating energy. IR transfers energy through electromagnetic waves. The parameter that can be changed for the IR process is the amount of energy applied to the food product: the power level. Applying different power levels (814 – 1342 W) for 15 mins to soaked soybeans achieved inactivation up to 95% of TIs.

IR still suffers from the downsides of standard thermal treatments, but it wins on much shorter processing times. The gain of this treatment is in improved nutritional quality due to the shorter times, but mostly it saves energy. The industrial IR equipment is currently available, which allows for relatively quick replacement of the more costly inactivation techniques.

Another form of radiation that is used in food processing is gamma. Gamma irradiation is used in the food industry primarily to preserve foods. The inactivation of TIs occurs by disruption, degradation, and aggregation of proteins in solution. This happens due to the release of oxygen radicals, which are formed by radiolysis of water. Radiolysis is the cleavage of chemical bonds due to ionizing radiation, which in the case of water would be the hydrogen and oxygen bond. When cleaved a hydrogen radical (H) and a hydroxyl radical (OH) are created, which are highly reactive compounds. Besides these effects, gamma irradiation also changes both the secondary and tertiary enzyme structures.

Gamma radiation is expressed in terms of the ‘gray’ (Gy) unit, which is in joule/kilogram. Using a dosage of 5 kGy soybean TI content was inactivated by 51%-63%. A higher dosage of 8 kGy only inactivated TIs by 38.65%. A large downside of gamma irradiation is the loss of vitamin C.

Gamma irradiation was not able to fully inactivate the ANF’s in common soybeans. If it is used it has to be used in combination with other techniques to reach safety limits.

Soaking

The final physical inactivation process is soaking. It is the simplest and cheapest method. This method hydrates the legumes and enables removal of water-soluble compounds. The anti-nutritional factors happen to be water soluble. While the effectiveness of soaking depends on temperature and pH, a longer soaking treatment will lead to more TIs that are removed from the legumes. Soybean soaking for 96 hours removed 35% of TIs.

One downside of this process is that, besides TIs, water-soluble proteins also dissolve into the discarded water. The same 96-hour process reduced the protein content of the soybeans by 26.3%.

With soaking it seems to be the classic ‘you get what you pay for’. It might be simple and cheap, but the inactivation rates are low, and the process is time-consuming.

For your reading comfort, I have decided to separate this post into three parts; to keep the length in check. This was part 2 out of 3, tomorrow part 3 will be posted. Part 3 will discuss chemical and biotechnological processes. Have a nice day!

References:

Inactivation Methods of Trypsin Inhibitor in Legumes: A Review

List of Legume Foods

Plant-based diet: Nuts, seeds, and legumes can help you get there

Nutrition basics

What are Trypsin & Chymotrypsin?

Study of Instant Controlled Pressure Drop DIC Treatment in Manufacturing Snack and Expanded Granule Powder of Apple and Onion

Radiolysis

Images:

Radiation sign

Related from @Altherion

Legumes: A comprehensive processing overview – Part 1

Survival of the Fattest

The Nano World – Atomic Layer Deposition

The Dancing Spider

Printing ‘Living Matter’

by FoodLabScience

Twitter

A scientist’s food for thought!

thanks for this relevant information!!!

You're welcome!