Influence of Bolt Length and Slope Ratio on Optimal Anchoring Angle

In recent years, accidents occur frequently due to slope collapse, open-pit mine landslides, and high slopes of highway engineering. So how to maintain the stability of the slope is becoming more and more important. What’s more, it is related to the safety of human life and property as well as the safety of the project itself.

At present, there are many ways of strengthening slopes, such as retaining walls, anti-slide piles, Reinforcing rock and soil slopes with bolts, etc. The latter is an important branch in the field of geotechnical engineering and has been widely applied to a number of projects, which can give full play to the stability of the rock and soil mass, improve the stress state and mechanical parameters of rock and soil to maintain stability.

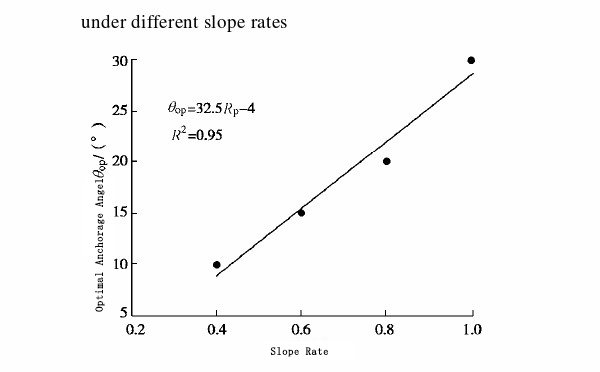

The optimal anchoring angle is an important parameter in anchoring engineering design and plays a vital role in the anchoring quality of the entire engineering. So, what is the effect of bolt length and slope ratio on the optimal anchoring angle? Through the calculation, it is found that the length of the rock bolt and the slope ratio of the slope has a great influence on the optimal anchoring angle, as follows:

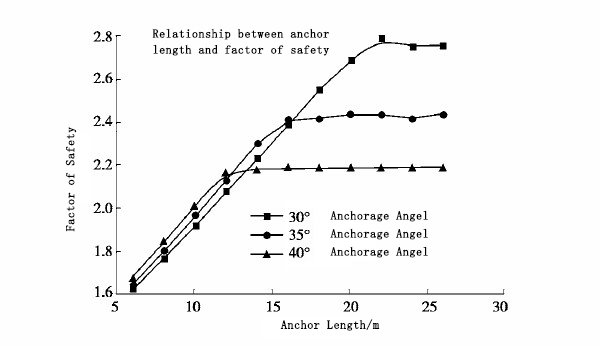

The safety factor of the slope increases first and then remains basically unchanged with the increase of the length of the anchor rod. There is an effective anchorage length. The larger the inclination angle of the anchor rod, the smaller the effective anchorage length.

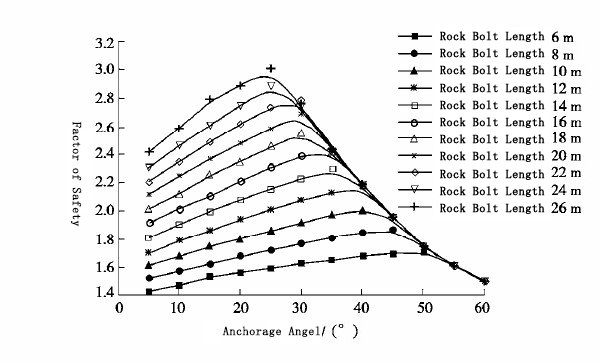

The safety factor of the slope increases first and then decreases with the increase of the inclination angle of the rock bolt, and there is an optimal anchoring angle, and the optimal anchoring angle decreases linearly with the increase of the length of the bolt.

When the inclination angle of the rock bolt does not reach the optimal anchoring angle, the slope ratio has little effect on the safety factor. However, when the inclination angle of the anchor rod reaches or exceeds the optimal anchoring angle, the influence of the slope ratio gradually appears. The higher the slope ratio is, the larger the corresponding optimal anchoring angle.

There are many types of rock bolts. Among these rock bolts, the self-drilling hollow rock bolts are the best with the advantages of less disturbance to the original rock, faster construction speed, lower cost, and safer.

The self-drilling hollow rock bolt system is composed of a hollow anchor bar, coupler, nut, drill bit, plate, and centralizer. It can combine drilling, grouting, and anchoring in one process. It is suitable for broken rock, loose soil, and geological conditions where is difficult to drill holes. It helps to ensure the anchoring effect in complex ground conditions and achieve the best construction result.

Sinorock divides the rock bolts into R thread and T thread systems. The sizes of the self-drilling hollow rock bolt include R25, R32, R38, R51, T30, T40, T52, T73, T76, T103, T111, T127, T130, T150, and T200. We can choose different product sizes and types according to different engineering requirements.