Episode 2 - From Water 🌊 Cooling to Oil 🛢️ Cooling!

Ok... I have made my mind up. Going to bring these as a series. Let me know what you think on the comments below. I have also tagged this series as #fromwatertooil so you can follow up next ones easily.

You probably watched the First episode, here. If not, give it a quick look (will help you understand a bit more).

It's time to Dip the Sauce!

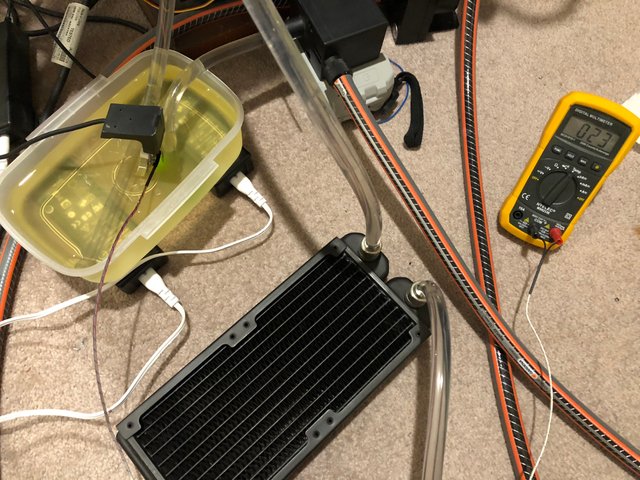

On the last episode, I have tested how water evaporation happened in a very open environment by exposing the returns a thin layer of fluid over a surface, by making it fall from an elevated point (compared with the suction point), that descends back to where it will be sucked by the pump again. This time, and after having the pump working on clean oil for a few days, I have decided to give it a go with a simple ASIC (around 10 Watts) and see how it goes. No FANS and just some heatsinks over the ASIC to minimize risks.

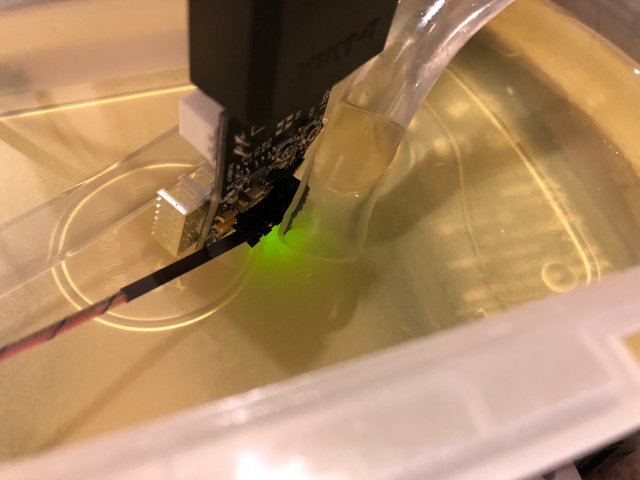

This experiment started with the oil temperature at 23C degrees. The oil was clean and I have no FANs on the radiator.

After some minutes the (black) heatsink temperature was around 31C degrees. Compared with the original air-cooled solution (FAN+heatsink) that had around 40-45C degrees! Ambient temperature is between 17-19C degrees.

Test Water Contamination!

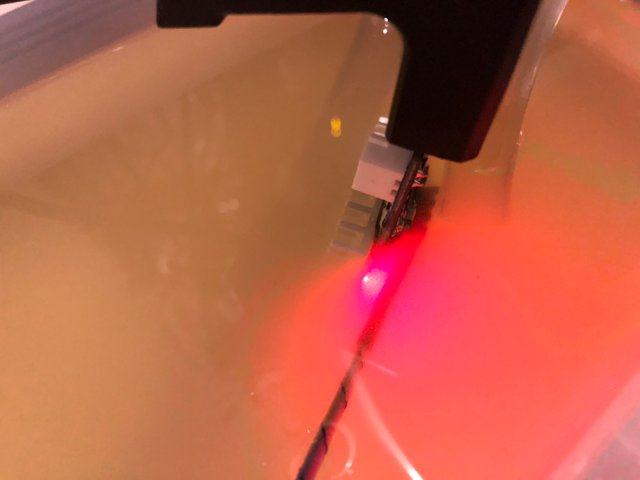

To test if there was any interference with water into the solution, I have added the approx 1ml of water to the solution and checked the changes!

Changes?

At first, I thought to notice around 1-2 degree drop after the water was dropped (and that would be expected). But now, I am not sure if that was not just because of the "extra" flow added when the viscosity reduced by adding water.

This will be running for the next days... until it becomes crystal clear. I will be monitoring the heatsink temperature over some periods, but I suspect it will be mostly between the 30-33C degrees. Remember, it's just 10 Watts, that mostly dissipate via direct contact with air.

Cooling Startup using clean Oil

After 16 hours

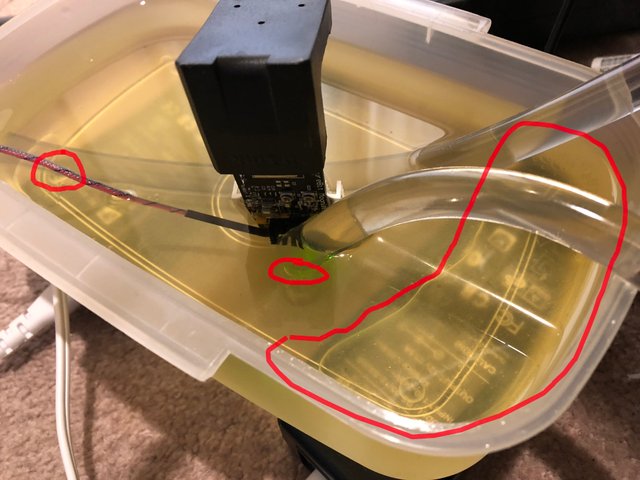

The water already settled. Now it's much easier for that to happen because the temperature of the mixture is probably higher. And also, due to the fact that there is no elevated surface for the water+oil mixture to be in contact with air, the evaporation is almost null.

I have highlighted in the picture above, where the bubbles of water are. Have to think in a good system to always expose the mixture to a large (and thin) open surface because of this problem.

Conclusion

Adding a bit of water was not enough to actually disturb the ASIC. No differences at all. Power consumption wise it was the same too. So this kindly makes me feel secure about using oil cooling systems in very high humidity places, as long you have a large (but thin, to force the water to be in contact with air) open surface for the evaporation to happen. This is also assuming the mixture temperature is higher than the air dew point, otherwise, evaporation will not happen.

That's all for Episode 2, see you on the next one.