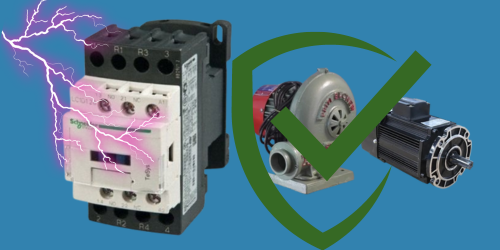

The Exact Reason For Using Power Contactor in Different Types of Motors

Power contactors are commonly used in motors for several reasons:

Control:

Power contactor helps in controlling the functionality of electric motors. It can be used for switching purpose, which means power contactor control switches that can open or close the circuit to the motor & this helps easy start and stop or reversal of motor rotation

Handling Current:

Electric Motor consumes high current on startup & during it’s operation and here come the power contactor to handle these high currents very effectively. Contactors designed with capable of carrying the current required by the motor without overheating and deteriorating the motors condition & it helps the motor to run for long term.

Protection:

Power contactor featured with built-in protection technology, such as overload relays or thermal protection. These protective device keeps tracking the current usage by the motor and disconnect power incase of overload or over heat.

Long life:

Power Contactor ensures the motor’s health for it’s long run by taking control of protecting by over heating issue, deteriorating, high current supply etc

Remote operation:

Contactors can be used to control easily through remote and automation. They can be activated by control signals from programmable logic controllers(PLCs), sensors or other devices.

This is why power contactors are very important electrical components in motor control systems as they provide reliable and safe control, protect the motor from damage and enhance the overall performance for long run of the motor.

Popular Ampere contactors used for different type of motors

The popular ampere ratings of power contactor used for different types of motors can vary depending on the motor's power requirements. Here are some popular ampere contactor ratings used for different types of electric motors:

Small Motors power requirement up to 5 HP:

9 amp contactors: These contactors are commonly used for small motors found in household appliance, such as refrigerator, washing machine and air conditioners.

Medium Motors power requirement between 5 HP to 30 HP:

25 amp contactors: These contactors are suitable for medium-sized motors found in applications like pumps, fans, blowers and small industrial machinery.

32 amp contactors: Used for controlling medium sized motors in HVAC system, conveyor and small machinery.

Large Motors power requirement between 30 HP to 100 HP:

40 amp contactors: These contactors are commonly used for controlling larger motors in industrial machinery, commercial appliances and equipment like mixers and small cranes.

50 amp contactors: Used for larger motors found in heavy machinery, industrial pump and compressor.

Very Large Motors were the power requirement above 100 HP:

100 amp contactors: These contactors are typically used for high-power motors in large-scale industrial applications, such as large crane, elevator(Lifts) and heavy duty machinery.

Important note: These ratings mention above is a approximate guideline and it can vary based on specific motor design, operating condition and electrical system requirements. So it’s always better to consult the expert level licensed electrician.