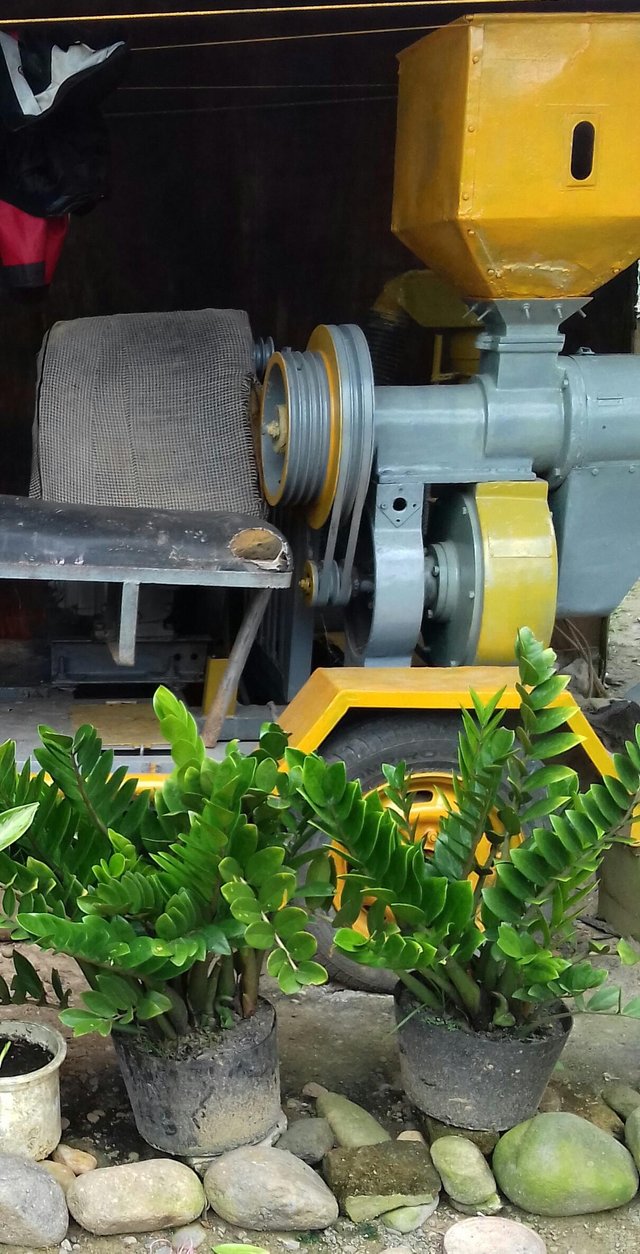

Kilang padi

The assembly industry of Kipakel in Cot Seurani Village, Muara Batu Subdistrict, North Aceh continues to grow rapidly, the article every day the demand keeps increasing, farmers seem to start to choose rice grind using the refinery service, because it is considered cheaper effective and efficient.

"Currently orders continue to arrive, in one unit of rice mill is assembled for approximately 15 days and able to grind rice as much as two tons, farmers began to be much helped, because this factory can directly enter from cheap to home farmers, so effective, cheap and efficient , "Said one of the workers in Tairun's tiling refinery manufacturing industry recently.

The paddy mill uses waste from used cars, especially some components that can be utilized such as steering cars, car seats and unused number of plates and car seats, then assembled, used as a three-wheeled vehicle. While the bloiler engine was ordered from Medan, North Sumatra.

"The machine is also used to perform the process of grinding rice at the same time used to drive a refinery like a ride on a car. Assembling a mobile refinery unit costs around Rp 23 million. The budget of that size has been completed and the car assembly plant can already be operational, "he said.

In one unit Kipakel done by two workers. "The raw materials other than waste used cars are not used, also use steel plate as the bottom section. Every single unit is done for fifteen days. So far, Kipakel orders have continued to arrive, because Kipakel's operations can go to remote villages, so farmers no longer have trouble bringing rice to large factories, "he said.

In relation to the presence of the paddy mill, it will reduce the turnover of existing rice plants, said Tairun, not possible. "The capacity of the mobile factory has the ability to grind at most two tons, and rarely the farmer grinds that much, most farmers use the services of kiliang paddies in small capacity, for example in one burl, weighing 50 kg, actually to facilitate farmers, while large factories are still grinding in large capacity, so baseball may be able to lower the turnover of large mills, "he said.

Besides, added Tairun, wage pick up every time the farmers do very thin mill in 10 kg, the wage is only 15 percent or 1.5kg wages, the price of rice is currently Rp 7,000 per kg. "It means that in 10 kg, the fare is only Rp 10,000, so it is not too burdensome for farmers, as well as the cost of the cost when carrying up to the big factory, it could be more than Rp 10,000

Thank you

This is the best post on Steemit. I gave you a vote now, ya heard?