Understanding the Lathe Machine: The Heart of Precision Manufacturing

Understanding the Lathe Machine: The Heart of Precision Manufacturing

The lathe machine is one of the oldest and most important tools in the world of manufacturing. From ancient woodworkers to modern metal fabricators, this versatile machine has played a pivotal role in shaping materials with precision. But what exactly is a lathe, and why is it so essential?

What is a Lathe Machine?

A lathe is a machining tool that rotates a workpiece around an axis, allowing the operator to perform various operations like cutting, drilling, sanding, and turning. Essentially, it shapes the material by removing excess layers until the desired shape is achieved.

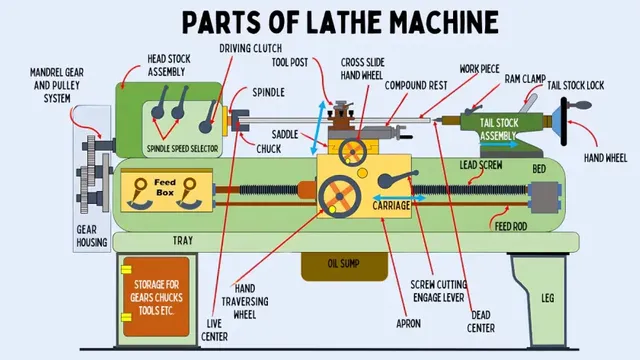

Key Components of a Lathe Machine:

- Bed: The sturdy foundation of the machine, typically made of cast iron, ensures stability.

- Headstock: Contains the motor and gears that drive the spindle, which holds the workpiece.

- Tailstock: Supports the other end of the workpiece when needed, especially during long operations.

- Carriage: Moves along the bed, holding the cutting tools.

- Chuck: Clamps the workpiece securely.

- Tool Post: Holds the cutting tools in place, allowing the operator to adjust them for different tasks.

Types of Lathe Machines:

- Engine Lathe: The most common type, used for general-purpose operations.

- Turret Lathe: Ideal for repetitive production tasks.

- CNC Lathe: A computer-controlled machine that allows for highly precise and automated operations.

- Wood Lathe: Specifically designed for wood-turning operations.

Applications of Lathe Machines:

Lathes are indispensable in many industries:

- Automotive Industry: For manufacturing engine components, shafts, and gear parts.

- Aerospace Industry: For creating high-precision parts like turbine blades.

- Jewelry Making: For crafting intricate designs in metal or wood.

- Furniture Making: Wood lathes are used to create detailed furniture parts like table legs and spindles.

Why is the Lathe Machine Important?

Lathes enable manufacturers to achieve precision and consistency in shaping materials. With the advancements in CNC lathes, operators can create complex shapes with minimal human intervention, speeding up production and reducing errors.

Maintenance Tips for Lathe Machines:

To keep your lathe in top condition:

Regularly clean the machine, removing chips and debris.

Lubricate moving parts to prevent wear and tear.

Ensure the chuck and cutting tools are always sharp and properly aligned.

Check the machine’s calibration periodically to maintain precision.

Final Thoughts

The lathe machine is truly the backbone of modern manufacturing. Its ability to shape and create precision components has made it indispensable across various industries. Whether you’re a seasoned machinist or a hobbyist woodworker, mastering the lathe opens up a world of possibilities in the art of shaping materials.

Do you have experience working with lathe machines? Share your thoughts and tips in the comments below!

This post should engage a wide audience on Steemit, sparking conversations about the importance and versatility of the lathe machine in modern manufacturing. Let me know if you would like to make any changes!