History of Electroluminescence Discover the story of (EL) Electroluminescence lighting, its discovery, development and implementation over the past 100 years. 10min read (2,347 words)

Electroluminescence (EL)

Part 1

2min 50s read (610 words)

Electroluminescence (EL) or the generation of light by the electrical excitation of light emitting phosphors has been around for many years. Electroluminescent was first observed in silicon carbide (SiC) by Captain Henry Joseph Round in 1907. Round reported that a yellow light was produced when a current was passed through a silicon carbide detector. An employee of the Marconi Company and a personal assistant to Guglielmo Marconi, Round was an inventor in his own right with 117 patents to his name by the end of his life.

The next recorded observation of Electroluminescence of any great significance came at the time of the Second World War, though there had been various reports of work done in this area during the 1920’s and 1030’s. In1936 George Destriau, once again noted that Electroluminescence could be produced from, this time, zinc sulphide (ZnS) powder after applying an electrical current to it so producing light. It was said that it was Destriau, who first coined the word "electroluminescence" to refer to the phenomenon he observed. Destriau, who worked in the laboratories of Madame Marie Curie in Paris (the Curies being early pioneers in the field of luminescence because of their research on radium), published a report of his findings.

During World War II, a considerable amount of research was done on phosphors in connection with work on radar displays (which was later to benefit the television industry in the form of better cathode ray tubes). Wartime research also included work on the deposition of transparent conductive films for de-icing the windshields of aeroplanes. That work was later to make possible a whole generation of new electronic devices.

In the 1950s, GTE Sylvania fired various coatings, including EL phosphors onto heavy steel plates to create ceramic EL lamps. During this period, most research focused on powder EL phosphors to get bright lamps requiring minimal power and with a potentially long lifetime. Research funding was cut back when it was determined that product lifetimes were too short (approximately 500 hours).

The first thin-film EL structures were fabricated in the late 1950s by Vlasenko and Popkov. These two scientists observed that luminance increased markedly in EL devices when they used a thin film of Zinc Sulfide doped with Manganese (ZnS: Mn). Luminance was much higher in thin film EL (TFEL) devices than in those using powdered substances. Such devices however were still too unreliable for commercial use.

Several large U.S. companies were also conducting research on ELDs in the 1970s, including: IBM, GTE, Westinghouse, Aerojet General, and Rockwell. All of these companies realised that ELDs had potential advantages over existing LCD technology in the following areas: Contrast, Multiplexing, and Viewing angle.

The most important problem that had to be solved before mass production of ELDs could begin was increasing the reliability of the EL thin film stack. Since the devices operated at very high field levels -- about 1.5 MV/cm -- there was a high probability that they would break down, especially if there was insufficient uniformity in the stack. Sharp, Tektronix, and Lohja Corporation in Finland were able to solve this problem between 1976 and 1983 using slightly different approaches.

The introduction to the market in 1985 of Grid and Data General laptops with EL displays from Sharp and Planar respectively helped to build the foundations for the nascent laptop computer industry at a time when LCDs did not have sufficient brightness or contrast to be used in commercial products. Both Planar and Sharp monochrome ELDs used a phosphor layer made from zinc sulphide doped with manganese (ZnS: Mn). These displays gave off an amber (orange-yellow) colour that was bright but also pleasing to the eye.

Creation & Development

Part 2

2min 10s read (575 words)

One of the key disadvantages of ELDs relative to liquid crystal displays (LCDs) was that until 1981 ELDs were not capable of displaying more than one colour. Even after 1981, colour ELDs were restricted to a limited range of colours (red, green, and yellow) until 1993 when a blue phosphor was discovered.

A SrS: Cu blue phosphor showing improved blue colour and efficiency was reported by Sey-Shing Sun of Planar in 1997. Planar demonstrated true white colour EL prototype displays using this blue phosphor in a SrS:Cu/ZnS:Mn multi-layer structure. The SrS:Cu phosphor will enable colour EL displays to be produced with a wider colour gamut.

Because of Planar's willingness to work with customers to adapt products for specific applications, it was able to command a price premium over the products of its main competitor, Sharp. By the late 1980s, Planar controlled over 90 percent of the world market for ELDs.

In spring 1995 Planar organized a consortium to develop the next generation of High Resolution and Colour TFEL Displays. This consortium was funded by the Department of Defense under the DARPA managed Technology Reinvestment Program (TRP). The total funding for the consortium was to be $30 million; half funded by the government and half by the consortium’s private firms. Other members of the consortium were: Allied Signal Aerospace, Computing Devices of Canada, Ltd., Advanced Technology Materials, Boeing, CVC Products, Georgia Tech Research Institute, Hewlett Packard, Honeywell, Lawrence Livermore National Laboratory, Los Alamos National Laboratory, Oregon State University, Positive Technologies and the University of Florida.

In 1989, the Defense Advanced Research Projects Agency (DARPA) began to fund work on advanced displays as part of its High Definition Systems program. DARPA issued a Broad Area Announcement in that year and in subsequent years asking for proposals. Planar won one of the first grants from DARPA in 1990 and used the funds to set up a laboratory to develop colour ELDs.

Electroluminescent displays (ELDs) have a venerable history starting with the experiments of Captain Henry J. Round in 1907, O.V. Lossev in the Soviet Union, and Georges Destriau in France. Electroluminescence was mostly a scientific curiosity until the invention of thin film deposition techniques and the discovery that a sandwich of conductors, insulators and phosphors could result in a very efficient and long-lasting form of emissive display. ELDs were very important in the early days of the laptop computer industry and remained important in niche markets for military, medical and industrial equipment where high brightness, speed, contrast, and ruggedness are necessary.

The rise of the colour TFT LCD display forced the ELD producers to engage in research on colour ELDs with the result that by the mid-1990’s there were multicolour ELDs on the market and full-colour AMELs in development for microdisplays. By 1999 the ELD industry was limited to two major players: Planar and Sharp. Planar acquired its only European competitor, the Finlux Display Division of Lohja Oy, (Finland) in 1990. Sharp remains committed to competing in ELDs but its main focus is on liquid crystal displays. Most of the important research on ELDs remains within the corporate laboratories of Planar and Sharp, but several publicly funded research laboratories and consortia have also made important contributions to ELD technology.

The use of Electroluminescence has been limited until relatively recent times. The major obstacles to effective use of EL in the past have been: low light output, susceptibility to moisture and ultraviolet, colour shift, cost-effective manufacture and short life.

Evolution of EL

Part 3

3min 10s read (664 words)

In the past several year's improvements have been made in the manufacture of EL lamps that have for the most part meant the product being recognized as a modern alternative to Neon and Cold Cathode lighting, where a non-pollutant light source is required. A non-pollutant light source being one that is not incandescent and so does not produce glare or affect night vision.

Not only that, but EL lighting proves to consume less energy, produces little to no heat and is much less bulky than incandescent lighting systems. It must also be said that the improvements made in EL lamps have provided higher output, long life phosphors, micro encapsulation to prevent degradation by moisture, ultraviolet absorbers, the control of colour shifts – dye conversion and provides an efficient, lightweight power source.

EL technology has expanded into other areas of use ensuring further development in key areas, including improved brightness and extended life expectancy of phosphors sure to benefit. To days EL lamps show massive improvement and are proving a viable alternative to incandescent lighting forms where application is appropriate.

EL lighting has several advantages over incandescence lighting which makes it a prime candidate for its replacement in subdued lighting and night time environment applications. EL provides improved night vision capability because it has no infra-red or ultraviolet emissions. This helps eliminate glare, improves contrast and visibility, and the product is flexible and durable, more reliable, is low maintenance, offers low power consumption and is cool to the touch when in operation.

It is for these reasons that the US Air Force made a recommendation for the usage of Electroluminescent lighting to be used on austere runways and in aircraft cockpits to increase operational readiness, system reliability, reduce operational and support costs and to eliminate the problems incurred using incandescent lighting: examples of which have already been mentioned above. The same Air Force study found that the Light Tape® lighting system was easily visible from distances up to five miles away. Notably Light Tape® light penetrates fog, smoke, snow, haze and other normally poor visibility conditions so opening new areas of application with the outdoor product.

In more recent years some EL lighting products have been produced and are available for purchase in the Far East, at extraordinarily low cost. Much of the product sold however has proved to be of poor quality and are ineffective, as the key component used in its manufacture; “Phosphor” was and still can be, of low quality so that brightness and product life expectancy are greatly affected proving that purchase of the product can be a false economy. This low-grade version of EL lighting products eventually led to the term electroluminescence becoming synonymous, for many years, with the word inferior. How can you take a product seriously when it doesn’t deliver? This is a fair comment when talking about the cheaper versions of the product but shouldn’t be directed at EL lighting in general. Currently available from the USA is an unequalled Electroluminescent lighting system that delivers the brightest, flat light bulb in the world with extended life.

Advancement in EL technology in the early 2000’s, were brought about while developing a new generation television screen (Plasma). Plasma televisions are backlit using the same phosphor technology as used in EL lighting, though obviously applied in a different way. For this new application of the technology to be viable the phosphor had to be of a much higher quality, the resulting light produced brighter and the life of the phosphor needed to be longer than any previously developed. New research and experimentation soon provided the technical advances to do exactly that resulting in a new generation high-quality phosphor that is brighter and does indeed have a hugely extended life span.

This breakthrough achieved, the resulting EL technology was used in the production of the Plasma TV one of the most sought-after reincarnations of the everyday household electrical product and has been a mainstream product for the past 5 to 7 years.

The Benifits

Part 4

1min 50s read (472 words)

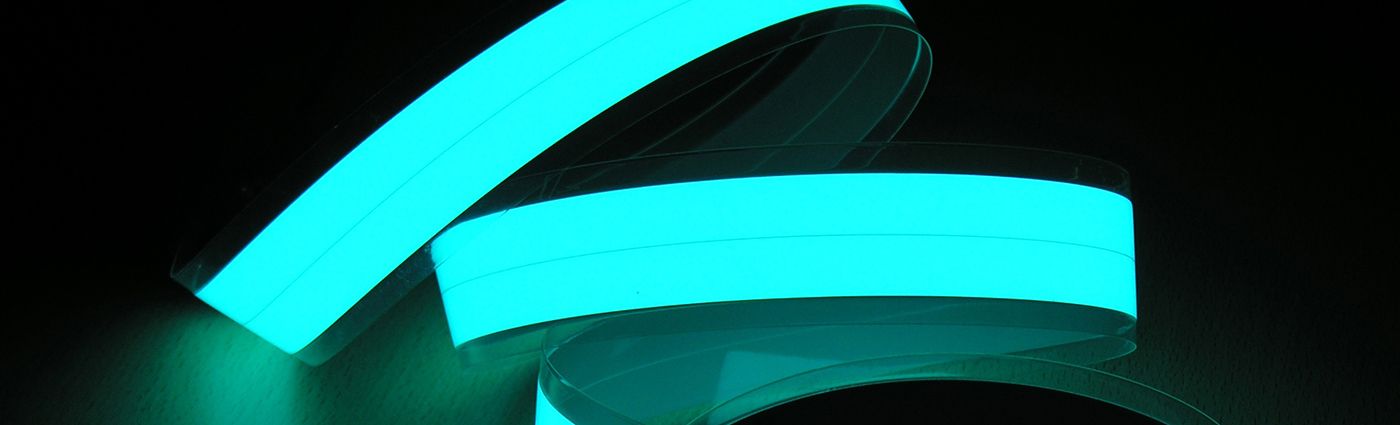

This evolution greatly benefited EL technology in general and what has become the product known as “Light Tape®” in particular as Light Tape® is the direct result of this EL advancement. Light Tape® is manufactured in the United States by ElectroluminX to a high specification, using Sylvania premium quality light emitting phosphors and Honeywell Encapsulant Systems. Light Tape® is the brightest electroluminescent light source in the world. It is in effect an incredibly thin, flat, flexible, moisture resistant light bulb. It can be supplied in a range of colours and widths, in lengths up to 300ft. Driven by specially devised power supplies; it can be used in flashing or steady state modes in indoor or outdoor application.

Light Tape® uses less than one-tenth of the power and is half the price of Neon and Cold Cathode display lighting, is easier to install and maintain, reduces light pollution, produces no waste heat or infrared light, is fully recyclable, and uses No Gas, No Glass and No Mercury.

Light Tape® with its wealth of benefits, versatility, ease of application, cost effectiveness and extremely low carbon footprint is fast becoming the chosen, viable alternative to more traditional forms of display lighting. (1 Watt per Meter at 25mm (1”) wide, a 100m length of 25mm wide Light Tape® only uses the same power as a 100w light bulb).

Architecture, Automotive, Advertising, Interior Design, Exhibitions, Events, Marine, Point of Sale, Hotels, Bars, Restaurants, around staging and entertainment areas, Emergency Egress and Health and Safety are just a few of the sectors benefitting from this exciting, innovative light source. And, imagine your individualised creative sign artwork with animated illumination, to command attention at a point of purchase or anywhere you need it. This too can be manufactured using the EL product, producing something that is truly eye-catching.

Light Tape® lamps are changing the way people think of a light bulb. Imagine a light bulb as thin as a credit card, available in any colour, which can bend around any surface, is available in continuous lengths of up to 300ft, for use indoors or outdoors, that costs only a fraction of what traditional light bulbs cost to operate. In fact, it is the most important innovation in lighting since the invention of the bulb.

For further details please log on to the Light Tape UK website which includes picture, animation and video galleries. Go to www.lighttape.co.uk to see the latest Light Tape® applications.

Information used in this piece was taken from the following sources:

A History of Electroluminescent Displays - Written by: Jeffrey A. Hart, Stefanie Ann Lenway & Thomas Murtha - University of Minnesota (1999)

Information on US Air Force research taken from a report presented to the PRAM Program Office, Aeronautical Systems Division Wright Patterson, USA, a NASA study for the Air.

Additional information: D.K. Hardcastle 2017