When You Seek You Shall Find....

Continue From "Work Place Is Our Second Home....."

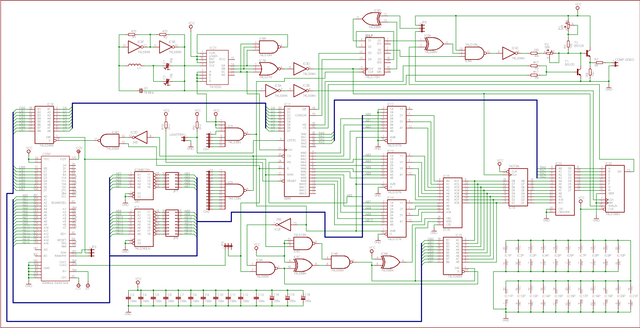

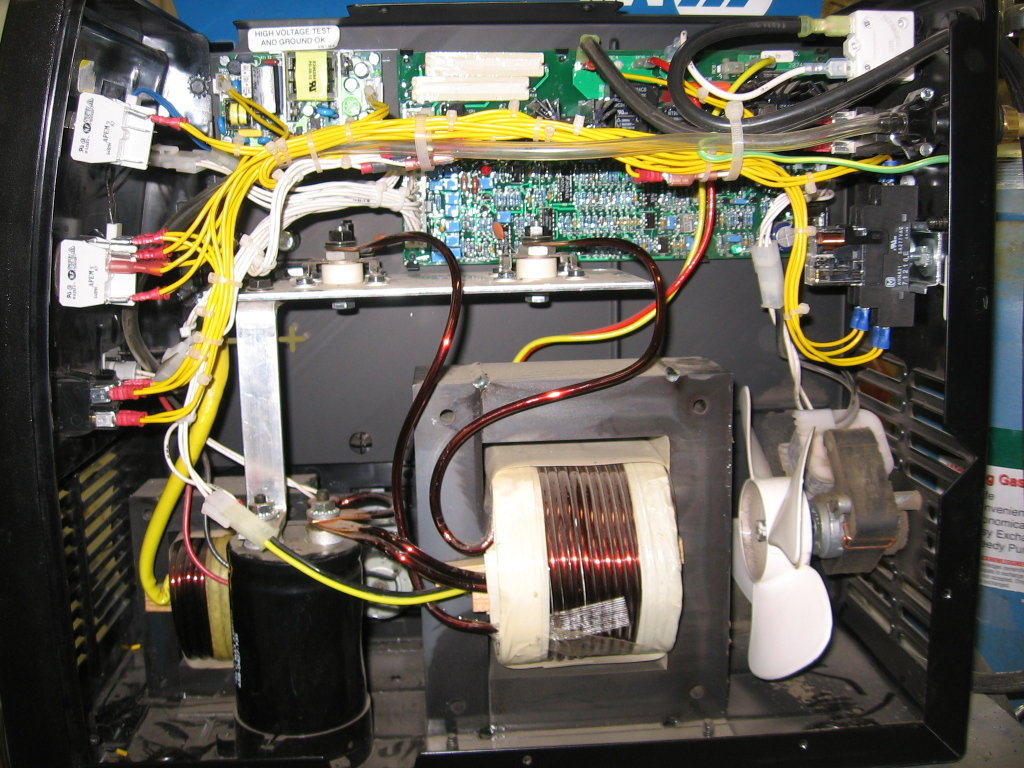

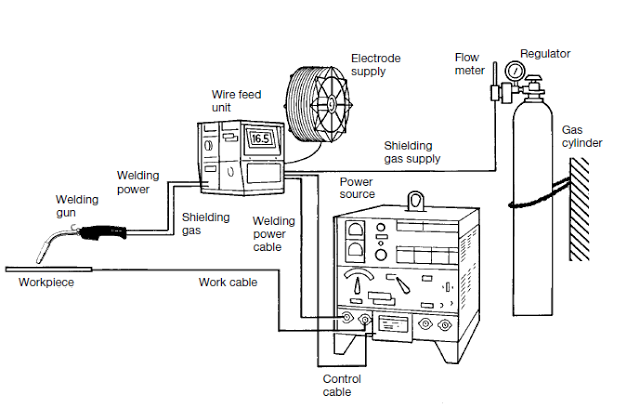

We became start to enjoy with our work place day by day. But we cannot control for burning MIG welding Machines control card burning issue. We called for meeting to find out to control or reduce down the cost of MIG Control cards problem. The biggest problem is we do not have electronic engineers in our company.

We called our supplier to give us electronic drawing for the machines. At first they do not want to give us the drawing and they want us to change higher capacity machines for our usage.

We have to throw back their words that they said to us was, those machine was good enough for our usage at the time before we purchase from them.

Actually they are right that they propose to us was 400 ampere series, because of the cost for the machines, we selected 300 ampere series of machines for our production usage. Because I found out from the suppliers that our company try to cut down the budget for the cost. But I told them to sort out the problem, because of MIG Control card damage was very high for every month.

They give us good price and service for repairing the MIG Control card, but we still have to find out to prevent not to burn and as well as we repair our self. So me and my friend, who was electrical engineer, went to Sim Lim tower (which building was selling al the electronic spare parts) and buy some of the electronic component and try to repair the control card by replacing new parts and it was successfully recover.

The cost of repair was less than S$ 10 and our supplier charged us at first S$300 per units per trade in, if repair cost will be S$150 for each control card.

We have achieve to reduce down the cost for maintenance budget but the cards are still burning. I ask my friend to modify to install the protect plan and he study and try to find out and tried to install the fuse at some of the places.

He place the fuse before the trigger for the circuit and also put for the grounding cable. It was quite helpful and success. After trying this he installed additional relay for the machine control card and it was very effective to prevent burning down our control cards.

And also we need to share that what we found out and we integrated to production crews, for them to troubleshot when the fuse is blow off. We need to provide all the fuse for them to replace by them self and teach them how to do as well.

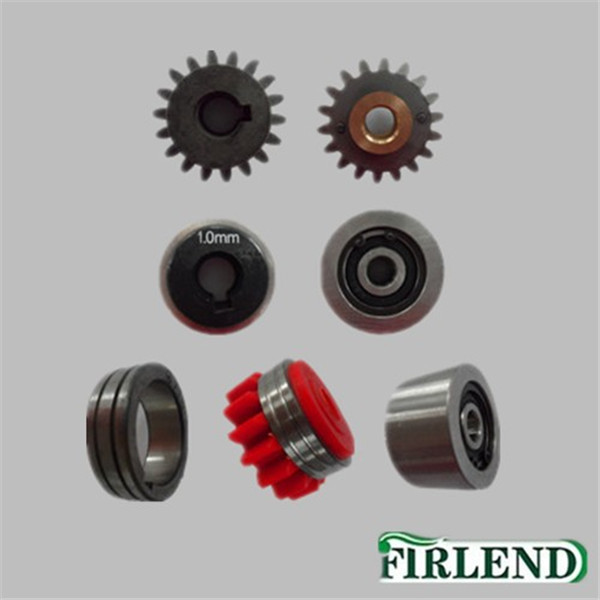

This problem is the one of the MIG Machines brand that we have and other brand that we are using was giving us other problem. The other MIG Machines was wire feeder roller always damage. Because the pinion and gear was make by plastic and if the welder apply more pressure on it, the pinion and gear are damage.

The course of applying the grater pressure was because of bad quality of MIG welding coil that we used and the skill of wire was pill off can cannot grip by the roller.

So what I do for this issue was I duplicate the roller dimension and change the materials and ask to fabricate by machining suppliers. It is happen to be the price was still cheaper than original roller price. We are happy that we can solve the problem easily without any consequence issue.

But I propose to management that to standardize our MIG Welding machines for our production usage and to top up our stock quantity need for our production.

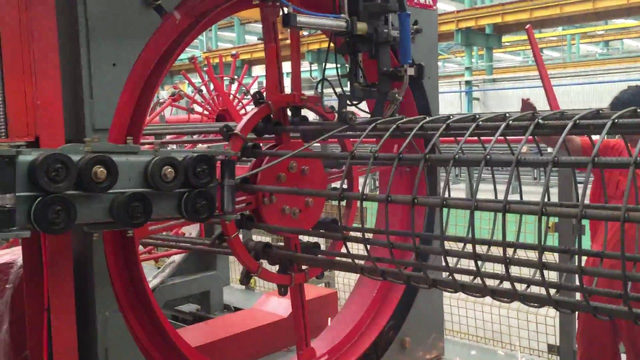

I get approve by management but need to replace auto welding machines for bore pile cage making machines to success by our other brand of MIG Welding Machines.

So I have to prove that other MIG Welding Machines are also can be use for Bore-pile cage making machines and to be use for auto welding machines for our production.

To Be Continue.....

GO WELL....(By: PatrickSanLin. MSC 007)

Photos credit: Google Image

Friend, very good post, you have very good content, keep it up, you have a great future, I welcome you to Steemit, I'll follow you

thank you so much buddy. i will try my best to be better.

I follow you, I view your other post

very good sir ji

thank you.

I think that dicussision is a solution at our work place.

really? what industries you are in?

Hmm, all sounds pretty technical. It seems to me like your solution saved the company some money, did your manager show appreciation?

yes, just a bit. i will continue with other post for what i am come across..

Take care on your job site , bro

i am no more working at there.....

Good

txs

Hi @patricksanlin , have you downloaded the DBS Paylah app?It is having event now,by giving away $S5 for the new user signing up with promotional code. Promotional code:CHAHDJ090

Thanks for you attention!