Re-Fueling The Future With Bio-fuels, Advance Generation of Bio-Fuels is Coming!

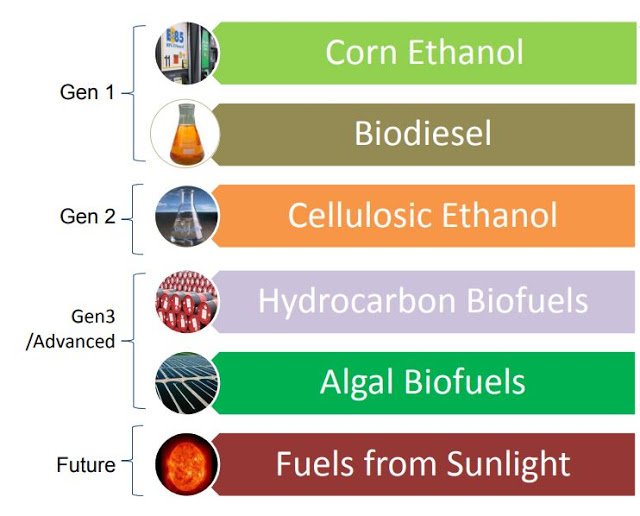

The traditional bio-fuels are being made from editable substances such as corn, mustard, sugarcane which creates a shortage in the food supply in many parts of the world.

The development is underway to produce the second generation of biofuels from in-editable substances like grass (lignocellulosic), paper, wood, stalks, etc. The third generation bio-fuels come from algae, that are low-input, high-yield feed-stock to produce Bio-fuels.

Today, the world is facing the energy crisis due to higher fuel consumption rate, thanks to increasing in population, and fluctuating energy prices result in inclination towards sustainable energy sources mainly from solar, wind, and bio-fuels.

Bio-fuels are fossil fuel substitutes that can be made from a range of agricultural crops and other sources of biomass. The two most common current Bio-fuels are ethanol and bio-diesel.

Why Bio-fuels have become a key issue?

Some of the critical reasons for going with biofuels are energy security (increasing oil prices, need for an alternative source of energy), to decrease greenhouse gas emission, and to promote rural development.

Bio-fuel is derived from farm produce and presently many countries allow using bio-fuel of some percentages in petrol and diesel. The grains include maize, mustard, soybean; sugarcane, etc. are used to make bio-fuels. Since these crops became cash crops and started earning huge revenue, in short time, there was a shortage of food in many countries and prices started rising that resulted in many controversies against bio-fuels.

In order to grow bio-fuel crops, the countries started buying land from poor countries and leasing them. In this way, new colonialism was born that got into the world’s biggest energy crisis. This is the first generation of bio-fuel conditions suffered a lot to its own success.

In the story of climate change and energy security, food crops used to fill fuels instead of filling people's tanks resulted in no change in food prices, but there was a dramatic change in use of land. More land was allotted to those crops which could be obtained from bio-fuel, whereas on the other hand, the land was reduced to several pulses, dal, wheat, sorghum, millet, and rice.

Sustainability Aspect

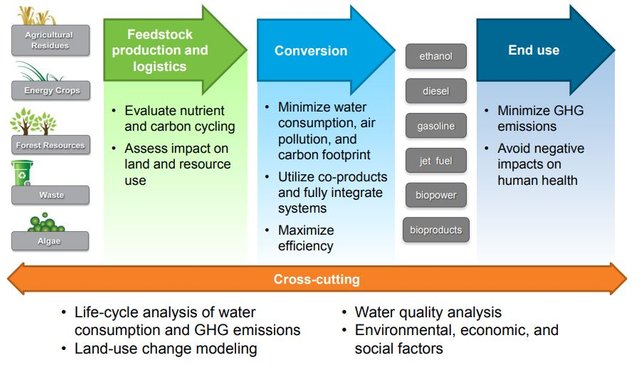

Current efforts are being made across the globe for developing and integrating the resources, technologies, and systems across the supply chain needed to grow a bio-fuels industry in a way that protects the environment.

Bio-fuels Life-cycle (Image source: NREL)

Now, it’s time to explore the second generation of bio-fuels with focused on science and technology. You must be confused with the term, ‘What is the second generation of bio-fuels?”. Bio-fuel sources in the second generation are about to develop a bio-fuel system from the waste of food crops like grasses, woods, papers and other rubbers, stalks, etc. The Bio-ethanol is one type of bio-fuels which can be added to petrol and it increases the fuel cost-benefit ratio.

In India, the government allows adding 5 percent bio-ethanol to petrol, and there was a proposal to further increase the percentage. While in Brazil, an addition of 25 percent of bio-ethanol to petrol is allowed.

Bio-ethanol is made from large amounts of cane in Brazil. It is challenging to get bio-ethanol from the food crops (waste, stalks), but not impossible. Last year, a group of biotechnology industry organizations located in Washington, DC (USA) estimated that second generation bio-fuels alone can reduce the annual imports of mineral resources up to USD 70 billion in America by 2022.

Bio-fuels Generations

The production of the first-generation bio-fuel will decrease as people start using the second generation bio-fuel sources.

Bio-diesel is made from oil-seed while Ethanol is made from sugarcane and grains. Biomass energy source is generated from the heat transfer of biomass. Ethanol is also made from cellulose which is available in grass, paper, wood, etc.

The production of second generation bio-fuels will increase across the globe by 2050 and could achieve around 250 billion joule of energy from it. The first generation bio-fuel production will be in excess of 50 billion joule in 2025 and as per some estimates, it will decrease by 40 billion joule energy in 2050.

Thus, there will be a major gap between sources of first and second generation of bio-fuel; the first and second generation of bio-fuel sources will generate around 40 billion joule and 250 billion joule of energy by 2050. It will be less than four percent of the world's primary energy demand.

However, Bruce Dale, the head of the bio-based technology at Michigan State University, East Lansing in America, is still more optimistic. According to him, biomass theory of the second generation can produce 350 billion liters of bio-fuels annually. This product was just as a full import of American oil.

To do this, there should be research to find out the ways that the inorganic walls of greenish cells should be analyzed and after digestion, it can be easily converted into digestive sugars using an enzyme. The fermentation in these sugars may result in bio-ethanol.

The above scientists and their associates have developed a technique called Ammonia Fibre Expansion (AFEX). According to him, this technique translates into 90% of cellulose bio-ethanol. In this technique, biomass is added to the ammonia-filled tank at 100 degree Celsius. It has 20 times more pressure than atmospheric pressure. After five minutes, the pressure is completely released with the explosion. The heated ammonia and rapid decrease in pressure result in breaking the cell walls. Its cellulose particle dissociates and separates.

Remember that vegetation is made of cells like living organisms. These cells are like a biochemical factory. The cells divide and the vegetation or organism develops. The cell consists mainly of three parts. There is a cell center called nucleus, another cell liquid, and the third is cell wall.

Due to the disintegration of the cell wall, the microscopic gap of its cellulose is reduced, which makes enzyme (enzymatic or prolonged) easier to reach cellulose molecules. This means that the more part of cellulose is converted into sugars. This is a fermentation of yeast with bacteria. As it turns out to be bio-ethanol or another bio-fuel. Approximately 300 liters of bio-fuels can be obtained from a ton of plant materials.

Going Forward

Currently, a wide range of methodologies and tools are available to assess environmental, social and economic indicators of first and second generation biofuels.

Bio-energy projects should be based on a regional assessment of feed-stock potentials (including regional sustainability aspects) and sustainability of feed-stock production.

The land resources for the production of energy crops are limited and in some cases, subjects to competing uses and further effort are needed to foster the production of 2nd generation bio-fuels from wastes and residues.

The process energy supply is often the biggest driver for environmental impacts during biomass conversion. The Life Cycle Assessment (LCA) approaches can help to identify and assess options for optimization.

If you enjoyed this post please Upvote, Resteem and Follow @futureentech for more creative and informative articles...

Go here https://steemit.com/@a-a-a to get your post resteemed to over 72,000 followers.