Mortise-and-Tenon Joints in Laser Cutting

In my recent posts I showed my laser cut projects that were joined by what I was incorrectly calling "pegs".

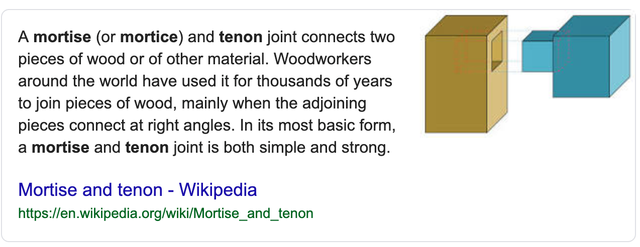

Thanks to @steampunkkaja, I now know the technical term for this type of "wooden peg" construction is

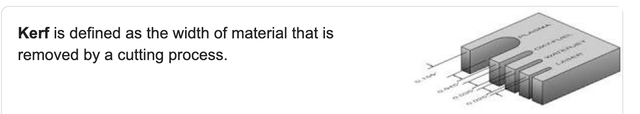

Quite simply, I make holes in my pieces, and strips of wood that match in size enough that when combined the pieces hold together through friction. The sizing requires awareness of another term:

You see, when cutting out the material along the lines you create, it will not produce a piece measured exactly as you defined it. In CNC, the kerf will be as a rule of thumb the width of your end mill.

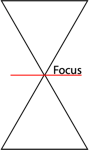

In laser cutting it is the width of your laser beam at that depth of focus.

For an engrave, the focus will usually be set to the surface, but for deeper cuts you will inevitably get a wider part of the beam, which produces a thicker line, and removes a wider strip of material, therefore your kerf is enlarged.

This means the measurement of your holes (mortise/mortice) needs to reduce and/or your tenon/peg needs to enlarge by that kerf amount to compensate and get snug fit.