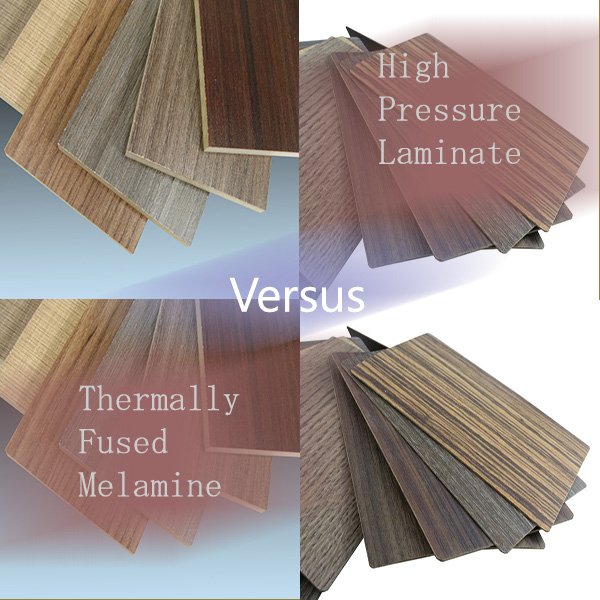

High Pressure Laminate (HPL) versus Thermally Fused Melamine (TFM)

HPL or High Pressure Laminate: HPL is about the most sturdy laminate accessible. It is made of a few sheets of paper that get fortified together utilizing high weight presses. It is utilized as a part of numerous level applications, for example, ledges and higher quality table tops.

On vertical surfaces, it is regularly utilized for entryways and cabinet fronts of cupboards. HPL has higher effect protection than most different covers. The item gets stuck on to the board for the most part utilizing a PVA resin glue. Normally a backing is utilized to forestall any warping or twisting. Sometimes the lamination is on the two surfaces.

Grades available:

Standard (also referred to as Horizontal grade) is .050" thick

Post form is .040" thick and is used to make post formed counters and tops

Vertical grade is thinner. .028 - .030" thick

Cabinet liner and some import grades are .02" thick

The four most common brand names in the US are Formica, Wilsonart, Pionite, and Nevamar.

Melamine or TFM (Thermally Fused Melamine) or LPL (Low Pressure Laminate)

Photo source: FeedYeti.com

Melaminepaper is thermally attached to particleboard or MDF boards. TFM must be connected to the front and back of the board to keep the board adjusted and balanced. Once in a while a darker brown backing supporter is connected to the base if shading or color isn't required. TFM or LPL is created in much higher volumes than HPL.

It is more slender (around .007") than HPL and is more cost effective. Since it is more slender, it has less effective protection to scrapes and impacts than HPL. The inner parts of cupboards, store shelves, POP show displays, and shelves are basic employments of this type.

Most office furniture makers make their items with some kind of overlay laminate material to bring down cost for the client, and most offer wide assortment of completions. Nonetheless, a typical confusion (which is incorrect) is that all covering laminate is the same. This isn't the situation. Regularly, makers will make items with either Thermal Fused Melamine (TFM) or High Pressure Laminate (HPL). So what's the distinction? It is safe to say that one is superior to the next? We should take a moment to dive into the subtle elements of each.

High Pressure Laminate

Photo source: accessfloorsystems.com

Comprises of a printed stylistic layout paper intertwined to different sheets of kraft paper immersed with a melamine tar like resin. High temperature and weight bonds every one of the sheets together in a thermosetting procedure. This makes an adaptable, sturdy bit of plastic-like material, which is then clung to a thicker center material (particle board or MDF) utilizing an assortment of glues. High-Pressure Laminate is warm, dampness, stain and scraped area safe, making it a safe decision and has an overwhelming use within office spaces.

Warm Fused Melamine comprises of that same printed style paper sheet, melded straightforward material (particle board or MDF). By precluding the way it is connected directly to kraft paper to start with, there is a significant cost savings, which make Thermal Fused melamine a moderate alternative. Like High Pressure Laminate, Thermal Fused Melamine is warm, dampness, stain and scraped area safe. It is likewise peel safe, since it's combined straight away to particle board (or MDF).

Be that as it may, High Pressure Laminate is a more adaptable choice. Since the stylistic theme paper wires to kraft paper, the outcome is an adaptable material that can stick to surfaces of every kind. It is bendable, so it can take after the bend of a work area. Warm Fused Melamine intertwines specifically to a strong bit of particle board (or MDF) that must be cut, not twisted.

The Thermal Fused Melamine surface is more slender than High Pressure Laminate, so it is much stronger against scratches and chips. And keeping in mind that the two materials are dampness and moisture safe, on the off chance that you exited a sweating glass on the surface of each overnight, the outcomes would be different to each one. The Thermal Fused Melamine surface would likely rise and unmistakably bubble causing harm the desk surface area. The High Pressure Laminate would just show negligible harm to the desk surface area, due to its predominant toughness. There are advantages and disadvantages to every material, and frequently the best decision relies upon the application.

So TFM is direct... so no peeling ... and the other HPL similar is basically resin and pressure with applied heat.

✅ @nadinescudero, I gave you an upvote on your post!

If you are interested in claiming free Byteballs ($10+), just for having a Steem account, please visit this post for instructions: https://steemit.com/steem/@berniesanders/do-you-want-some-free-byteballs