Making Something Out Of Nothing

Hey guys! Today I want to share with you something that I made from scrap metal that I picked up from the scrapyard. I've been meaning to post warning signs on my property for a while now but I wanted a nice post or something to affix them to.

I started out by using this piece of steel as my post.

At first glance, this doesn't look like it would be worth hanging on to, but it's good steel! A little work with a grinder and she will be good as new! Removing the paint and rust makes welding much easier.

I beveled the end to make it easier to drive in to the ground.

Once the post has been prepared, I begin to work the sheetmetal.

This piece is about a 16th" thick so it should work just fine for what I'm using it for.

I started out by tracing around the sign that I will be using with a metal punch.

While I was at it, I went ahead and marked the mounting holes.

I used a straight edge to help make a clean and straight cut.

I used this Milwaukee metal cutting saw to cut the pattern out.

The saw cut through the metal like butter and now I have the backing for my sign.

Even though the saw made nice cuts, there's still razor sharp edges and corners that need to be dressed up.

Once I rounded the edges, I deburred all the edges.

The plate is almost ready to be welded to its post, but first I want to remove the paint so I will have clean metal to weld to.

One more test fit before I marry the pieces together.

Once center is found, I clamped the pieces and began to spot weld the pieces together. Welding a thick piece of steel to thin sheetmetal can be tricky.

Yes, this is overkill with that many welds but it's okay, it didn't cost any extra.

I used Rustoleum paint to help preserve the metal.

Now I need to make a box to house the motion sensor. The sensor is weatherproof but I wanted a nice place to mount it and at least give it a little protection.

I started out by cutting another piece from the same sheet of metal. My idea was to score the metal and then bend it to a 90° angle to make a roof over the sensor. I used my vice to help bend the metal and it worked perfectly.

Now I could just leave it like this but nooooo, I want to make some sides for it!

I decided to taper the sides so it wouldn't interfere with the range of the sensor. Using the same sheet of metal, I measured and cut two triangles using my jigsaw.

Talk about a sharp ass piece of metal, this thing is dangerous.

Pretty straight cuts if I do say so myself 😁

Now I will prefit the pieces prior to welding. I used magnets to hold the pieces in position while I welded them in place.

I attempted to use my oxygen and acetylene set up to weld these because the metal was so thin and where its on the edges too, it was going to be difficult to weld without burning through.

After getting everything ready and set up, I discovered that I had a piece of debris in my tip, so I had to stop and clean it out.

Tip cleaners

File to clean the face.

I will be honest, I butchered up the sides using my oxy/acetylene set up. I haven't welded this way in a long time so I was extremely rusty. I ended up turning my MIG down as far as it would go and that worked okay.

After everything has been painted, I affixed a metal screw in the box for the sensor to mount to.

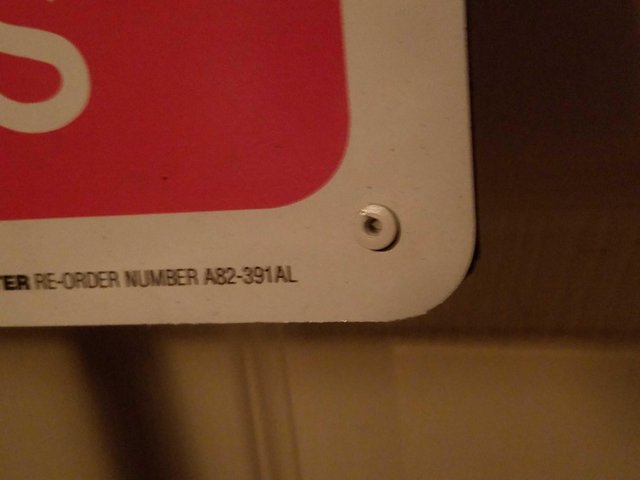

Last step...mount the sign to the plate. I thought about using self tapping screws to secure the sign but I decided to use painted pop rivets instead. It makes for a much cleaner look, dontcha think?

It's finally finished and ready to be stuck in the ground!

Is this a little overkill for just a sign post? Maybe, but I didn't mind doing the work and all the materials were free, so why not? Plus, my dad always told me that if you're going to do something, do it right the first time.

I hope you enjoyed this post about making something from nothing. If you have any questions, please feel free to ask!

@bluelightbandit

Non Ducor, Duco

Absolutely nothing wrong with overkill...it is seriously underrated today with everything (it seems) being manufactured to fail prematurely.

Ha! Preaching to the choir, girlfriend!

That was a pretty awesome job, @bluelightbandit! I do like the way you work! If you are going to do a job, do it right the first time!

Thank you CC!

Nice job!

Thanks!

Thank you for your continued support of SteemSilverGold

Nice work and it look's like it will last a long time! I'm not that good at welding so I would use nuts and bolts.