What air compressor do I need?

In this purchase guide, I explain exactly what to look out for when you want to buya new air compressor. I will cover the basic specifications and help you find the right type of air compressor for you.

Which air compressor to buy?

• You want to buy an air compressor, but you are overwhelmed by the many options and the many types of air compressors?

• You want to buy an air compressor, but do not know where?

• You are worried that you are buying the wrong type, size, or model of air compressor.

• You do not know if you need a single-stage, two-stage or rotary screw compressor.

Do not worry, you're in the right place. Welcome to the purchasing guide for air compressors!

In this purchasing guide for air compressors, you will learn:

• What is the right kind of air compressor for you?

• What is the right air compressor for you?

• This saves you money when buying your air compressor.

• How to save money in the long term: energy costs and maintenance costs

• Which options you need and do not need

• The most common mistakes when buying an air compressor.

Ready? Let's go!

The right air compressor for you

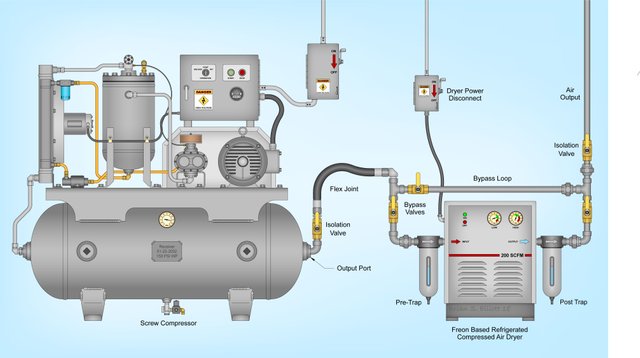

There are so many types and models of air compressors that are easy to confuse. In addition to the many models and sizes, there are additional options such as dryers and filters.

Do not worry. Once you know what to look for, buying the right air compressor is pretty easy and straightforward.

Pressure against capacity

The right type of air compressor for you, and the right model / size depends largely on the required pressure and capacity.

It is important to know the difference between pressure and capacity and how they work together.

Overview of the brands and series of screw compressors

There are a few compressor manufacturers that are interesting to us. These manufacturers all have different rows (or lines) of screw compressors.

They differ in capacity, pressure or options (but they are all screw compressors).

To make you understand the available screw compressors, I have created this overview.

Next: Overview of Screw

Compressors Manufacturers, Models and Models Buy your screw air compressor.

Now you should have a pretty good idea of it:

• Which air compressor is suitable for you?

• The pressure you need

• The capacity you need.

Now is the time to find the perfect air compressor for you!

I have created two buying guides for you: the purchase instructions for reciprocating compressors and the purchase instructions for screw compressors.

Compressor types - The right air compressor for you

There are so many types and models of air compressors that are easy to confuse. In addition to the many models and sizes, there are additional options such as dryers and filters.

Do not worry. Once you know what to look for, buying the right air compressor is pretty easy and straightforward.

To make the right decision, we need to know:

• The best kind of air compressor for our application.

• The required pressure.

• The required capacity (flow rate) of the air compressor.

• Extras and options...

There are basically two types of air compressors that are of interest here: the screw air compressor and the reciprocating compressor. It is very important to choose the right type for your situation. I'll give you some basic rules of thumb so you can be sure to buy the right type.

Then there is the pressure and the capacity of the compressor. This is about size and power.

A too small air compressor will not do the job, but too big a compressor can be even worse (think: wasting money on too expensive a compressor, higher maintenance costs, and higher energy costs). In this case an 8 gallon compressor will be perfect to do this type of job.

Ultimately, we have to decide if we need extras like compressed air dryers, filters and the like.

I will treat these points individually.

But let's talk about the basics first: air pressure and compressor capacity.

What type of air compressor do I need?

The two most popular types of air compressor are:

• Reciprocating compressor (piston)

• screw compressor

Other types include scroll, turbo and rotary vane compressors, but these are mostly used for special applications. Forget it now, let's focus on the two main types of air compressors: the reciprocating compressor and the screw compressor.

The piston compressor

The reciprocating compressor compresses air using one or more cylinders / pistons. The pistons move up and down within the cylinders to compress the air. For a detailed explanation, see my Piston Compressor page.

Piston compressors:

Can be up to very high pressure (7 - 1000 bar or 100 - 15,000 psi)

Low capacity

Designed for intermittent use

Piston compressors are relatively small compressors. They go up to about 10 hp (or 7 kW). They are often found or used for:

• workshop

• garages

• Do-It-Yourself / Home

• Small businesses

• Construction work (Nagler etc.)

I will discuss the differences and benefits of single-stage versus two-stage and duplex air compressors in the piston compressor purchase instructions.

The screw compressor

The screw compressor compresses air through two screws (rotors), which rotate in opposite directions in the housing. Air is trapped and compressed between the rotors. For a detailed explanation, take a look at my screw compressor page.

Screw compressors:

• Are low pressure (7 - 15 bar or 100 - 215 psi)

• Are high capacity

• Are designed for continuous use (24 hours a day)

Screw compressors are large, industrial machines. They start at about 10 HP (7 kW) and go up to more than 1000 HP (700 kW). The biggest machine I worked on was a 2000hp (1500kW) air compressor!

How do you know which type of air compressor is right for you

If you need a small amount of air, use a reciprocating compressor and do not use compressed air continuously (for example, in a pneumatic tool workshop). If you have some large tools that need a lot of air (but you only use them occasionally), it is better to install a larger air tank than to buy a larger piston compressor or even a screw compressor.

If your compressor is over 60% of the time, it is often better to get a piston compressor. Piston compressors do not mind resting (even better not running all the time). Keep in mind, however, that when using compressor air, the capacity of the reciprocating compressor is high enough.

If you need high pressure (over 1500 psi), a piston compressor is the only way to go. Screw compressors can be operated up to a maximum of 10 bar.

Get a screw compressor if you need air all the time. If you have a large workshop that uses compressed air all the time, or if you have a factory with one or more machines that use compressed air.

Screw compressors do not stand still; it makes you rusty and old.

Get the best air compressor here, buy today. We have a range of state-of-the-art piston, screw and dental compressors. You can buy your screw air compressor from here.