#learnwithsteem || Part-4 || Functionality of feed pump & cooling tower in wastewater treatment and how it works. Problems encountered and their solutions.

Greetings dear friends,

How are you all my friends? I hope all of you are well by the grace of Almighty Allah. Alhamdulillah I am also well by the grace of Allah. I am also well by God's grace and your love. It's been a week and I'm here with my next part.

So before I start the new part I am sharing the old part link for your understanding. And topic I discussed in Part -03 is ETP plant equalization tank requirements and how the wastewater treatment process works from there.. And today I will discuss Functionality of feed pump & cooling tower in wastewater treatment and how it works. Problems encountered and their solutions. Besides I also discuss many more things. So let's start.

- Feed pump is used to lift water from equalization tank. Here we have 2 pumps which are run at regular intervals. And we operate these pumps through panel board switches which are operated manually or automatically.

- The pipe depth of these two pumps used here is slightly less than one another. And this pump is used to control the flow of water in our plant. That is, there is a valve on the outside of the pump from where we can control the flow of water transfer. And I mentioned earlier that our plant can treat 180 m^3 of water per hour but we treat 100 to 120 m^3 of water. And the water that accumulates in our plant in equalization goes through all the stages for 27 hours and then comes out after treatment.

- I think one of the reasons I already mentioned above is to create water flow.And another main reason is to cool the water. The temperature of this water is above 38.0°c when it first enters the equalization tank. And since our plant is a biological plant, the water is cooled through a cooling system to make it suitable for bacteria to live in.

|  |

|---|

- The water from the feed pump is first sent to the cooling tower where the water is cooled with the help of fans. A beautiful cooling tower has been installed here. After the water cools down, it is re-piped to the water tank from where the further purification process starts.The cooling tower is installed on the third roof of our plant and from there the water comes back down through pipes.Cooling the water makes it suitable for bacteria to live in. And since ours is a biological plant, we use aerobic bacteria.

In this way the waste water goes from the feed pump to the cooling tower and from there the water is cooled and returned to the plant tank for the next step.

- Since these are machines, they can become useless or have problems at any time. And one of the problems that our plant faces is clogging or leaking water in the feed pump pipe. So we take regular measures for this. Sometimes the problem is solved by changing the pump.

|  |

|---|

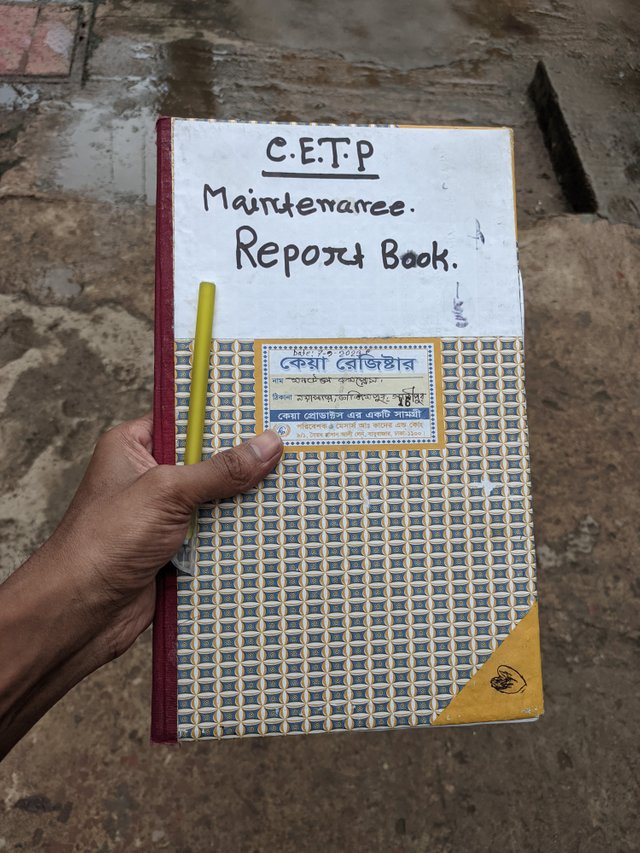

- Again when there is more dirt accumulation the water rise is very low or when the water rise is repeatedly stopped then we write a report and take it to the maintenance room from where the mechanical man comes and repairs it.And this sector is open 24 hours so we can take help in any situation.

|  |

|---|

- Also, we clean the cooling tower 1 to 2 times per month to reduce the amount of dirt and keep the water cool and flowing. And the cooling tower has very few problems so it is only cleaned periodically.

That's it for today. In the next part, I will discuss the next step in the ETP plant's water purification process. Till then stay safe, stay healthy. Have a good day.

@ steemcurator01

@ steemcurator02

@ pennsif

Thank you, friend!

I'm @steem.history, who is steem witness.

Thank you for witnessvoting for me.

please click it!

(Go to https://steemit.com/~witnesses and type fbslo at the bottom of the page)

The weight is reduced because of the lack of Voting Power. If you vote for me as a witness, you can get my little vote.

https://twitter.com/enamul171/status/1710647258419769569?t=5kxfuLg7c81T5oU3TUjoBA&s=19

প্রিয় ভাই, আপনার ইটিপি প্লান্ট দেখে আমার প্রতিদিনের কাজের অংশ গুলো মনে পড়ে গেল। আমাদের ফ্যাক্টরিতে কয়েকটি কুলিং টাওয়ার রয়েছে। হিট এক্সচেঞ্জার রয়েছে। সবগুলো পানি কুলিং এর কাজে ব্যাবহ্রত হয়। আপনার লেখা অনেক সুন্দর হয়েছে। শুভকামনা রইলো আপনার জন্য।

জি, আপনি ঠিক বলেছেন। ধন্যবাদ ভাই আমার পোস্টটি পড়ার জন্য এবং সুন্দর মন্তব্য করার জন্য।

TEAM 1

Congratulations! This comment has been upvoted through steemcurator04. We support quality posts , good comments anywhere and any tags.