Underground Transmission Line (Draw-in-system Method)

In my previous post I outlined the rules and descriptions of laying a direct cable among the three methods of laying Underground Transmission Line. You can also read my previous post. Today I will share with you some general ideas about Draw-in-system.

Draw-in-system

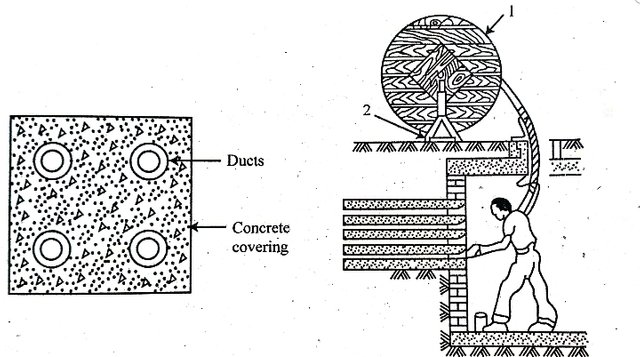

Where repeated digging is costly, inconvenient, and in the case of rail or road crossings. Laying cables in some pipes or ducts in the ground or placing cables in them is called draw in system. In this system, one or more parametric concrete or iron pipes are placed directly in the trench or inside the concrete casting in the trench as required.

These pipes are called ducts. In some cases, a multiway duct is also used. The ducts are placed in such a way that the surface of the duct is 75 cm below the ground for voltages below 33KV and 105 cm below the ground for voltages above 33KV and above.

The diameter of the duct is given

The overall diameter of the cable | The inside diameter of the duct |

|---|---|

| 60 mm ( to 2⅜") | 100 mm (4") |

| 60-90 mm ( to 2⅜" - 3⅝") | 125 mm (5") |

| 90 mm (up to 3⅝") | 150 mm (6") |

The three core cable is placed in a ducted duct. Three core cables of multiple circuits should be placed in the duct as well. Three ducts should be placed in triangles for three single core cables of three phases.

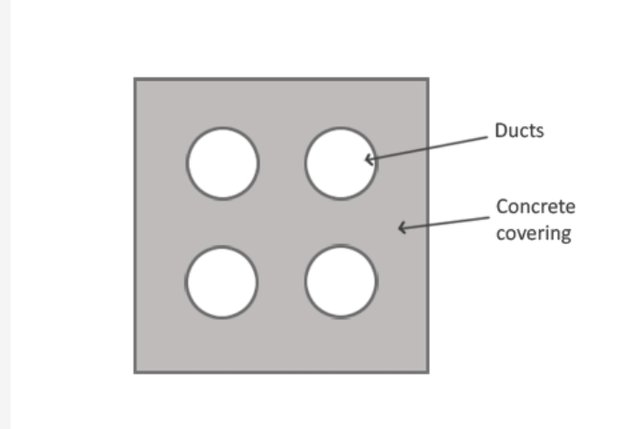

Manholes or Draw-Pits have to be placed occasionally (75m to 125m apart) to facilitate cable pulling in the duct. A guide bell should be attached to the mouth of the duct in the manhole to prevent injury to the cable during insertion into the duct. Once the duct is installed and the manhole is made, first a rod of 2-3 m length from the manhole with patch cut on one side and socket on the other and inserted into the duct across each other. When the head of the rod reaches the other manhole, a rope of steel wire is tied to the head of the last rod of the rail and the rod is pulled from the next manhole one by one and the rope is pulled to the manhole. This time the cable is tied with the rope and pulled into the duct. Pulling grip is used for narrow and short sections and pulling eye is used for heavy and long sections to attach the cable with rope. The cable in the duct is usually not given to me. The cable joint is to be made into the manhole.

Advantages and disadvantages of Draw-in-System:

Benefits:

- In this method cable network can be repaired and replaced without lifting the soil.

- Cables are not armored so joining is easy and maintenance cost is low.

- In this method, the cables are mechanically strong, so there is less chance of mechanical error.

- It is especially useful for densely populated areas.

Disadvantages:

- The initial cost is very high.

- Current carrying capacity decreases due to proximity of cable grouping.

- This method is used in all places (e.g. workshops, road crossings, important installations etc.) as excavation work is costly.

Not used. - Fault is difficult to identify.

Nice to read your post .

Keep posting and stay with our community.

Thank you

This post has been upvoted by @boss75 from @steemcurator07 Account with support from the Steem Community Curation Project.

For more updates, keep following @steemitblog.

Best Regards!!!