Flexible Batteries for Flexible Electronic Devices

Currently, one of the most active research issues is the development of flexible electronic devices. A few examples of applications for these technologies range from electronic skins (flexible electronic devices that can sense environmental conditions, such as human skin) to artificial muscles and wearable health monitoring systems.

When subjected to mechanical loads, flexible materials with good conducting qualities maintain their conductivity. This is one of the most fundamental components necessary for all of these devices. Such materials, on the other hand, are tough to come up with.

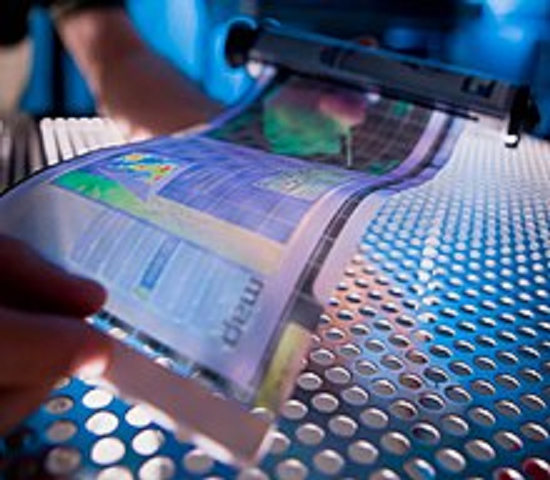

Image

To present, two technologies have been used to make flexible, conductive materials: elastomer and carbon nanotubes. In the first technique, electronic components measuring nanometers (billionths of a meter) were attached to flexible polymers using adhesives (long chain molecules made up of repeating units).

However, the amount of conductor present in the materials produced in this manner was insufficient, and the conductivity of the materials produced in this manner was inadequate. During the second procedure, conductive fillers were distributed throughout the flexible polymer matrix. This process results in materials that are both capable of carrying a huge amount of current and of self-repairing themselves.

The amount of hard, conductive material in them, on the other hand, grows as the amount of flexible polymer in them increases, and as the quantity of hard, conductive material in them increases, the amount of conductivity declines.

Dr. Nicholas Kotov, from the University of Michigan, led an international team of researchers that developed a revolutionary method for producing flexible, conductive materials. Flexible, conductive material is used to construct a tiered framework in the new technology. Each layer contains both positively charged polymers and negatively charged gold nanoparticles, which are alternating in charge. The compositions of the strata, on the other hand, differ from one another. Depending on the layer thickness, the mass fraction of gold nanoparticles can reach up to 90% in the outermost layers and drop as low as 50 percent in the middle layers.

According to the researchers, the layered structure of the material allows for fine tuning of its mechanical and electrical properties. Although the material has been stretched in either direction and has had its length tripled, it has retained its metallic properties (conducting electricity with very low resistance).

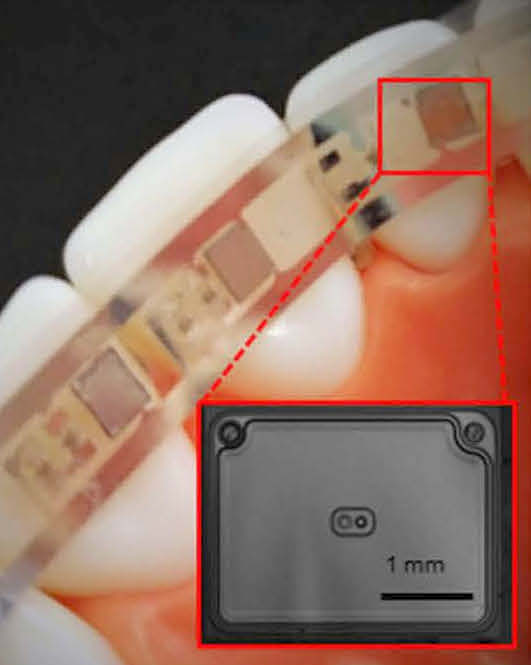

Image

The researchers used their new material as an electrode in a lithium-ion battery to put it through its paces. According to the results, the battery has a charge-discharge capacity of 100 mAh/g at a current density of 0.5 A/g and a charge-discharge capacity of 100 mAh/g at a current density of 0.5 A/g. Even after 1000 recharges, the battery retains 96 percent of its original capacity, demonstrating its durability.

Flexible batteries, according to the researchers, can be created by combining flexible conductive materials with the novel process of manufacturing. These batteries have the potential to be employed in medical implants as well as the construction of flexible robots that can replicate the behavior of living organisms.

References: