Diesel Generator : Device and principle of operation

When purchasing a diesel generator for a particular purpose, it is important to understand the principle of its operation, because without understanding what exactly you are dealing with, you can accidentally lose sight of the signs of malfunctions, and simply violate the rules for operating this unit.

The most common diesel generator (which is suitable for a home or small business as a source of backup power supply) consists of several main units installed inside a frame, often protected by a noise-absorbing casing: a fuel tank, a diesel engine, a manual starter, an electronic automatic control and voltage stabilization unit. , alternator (directly alternator ), battery with charger. In addition, the engine lubrication and cooling systems, as well as the exhaust gas system, are implemented within the diesel generator frame.

The principle of electricity generation in this type of generator is based on the use of a diesel engine in combination with an alternator. Diesel overhead valve internal combustion engine allows for reliable mechanical rotation of the generator rotor without excessive noise, overall build-up and excessive exhaust, in comparison with other solutions on liquid fuel.

The energy of the combusted fuel is converted here first into the energy of the expanding gas, which presses on the pistons, and they rotate the crankshaft. So the chemical energy of the fuel is converted into mechanical energy of the crankshaft rotation. The crankshaft, in turn, transmits rotation to the generator rotor.

Source

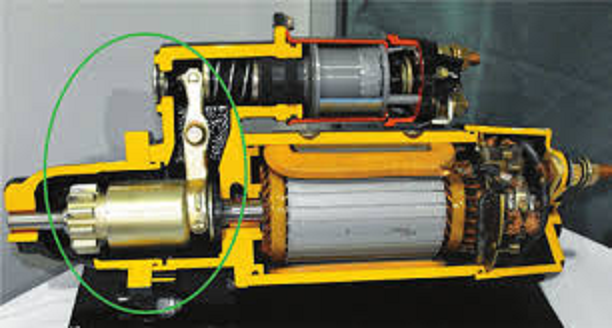

An alternator (or alternator) can be synchronous or asynchronous, inside its housing is a rotating rotor (with or without brushes) and a stationary stator with a winding. The magnetic field of the rotating rotor crosses the stator winding, inducing EMF in it, thus creating an electric voltage and current with the parameters required by the consumer.

It is believed that a synchronous alternator is more suitable for powering high-power loads, and for voltage-sensitive consumers such as refrigerators, an asynchronous alternator with a better ability to maintain a constant output voltage is more suitable.

Source

So, a diesel internal combustion engine transmits rotation to the rotor of an alternator. And for the normal operation of the internal combustion engine, it is equipped with a battery with a charger, a manual starter, a lubrication system with a pipeline and filter, a cooling system, as well as a fuel supply system with a pump, pipeline and fireboxes. Large industrial models of diesel generators are additionally equipped with a system to maintain the thermal regime of the engine at an acceptable level, as well as an electrical distribution system.

The cooling system in a modern diesel generator can be liquid or air. The simplest household generators are traditionally air-cooled, while industrial models are liquid-cooled. There are turbocharged and naturally aspirated air systems.

Source

The operating time of a diesel generator is limited by the amount of fuel in the fuel tank and depends on the power taken from the generator. Typically, fuel consumption for diesel generators of different models ranges from 6 to 50 liters per hour, depending again on the power taken off and the rating of a particular unit.

The range of output voltages typical for a mobile diesel generator is from 200 to 400 volts, and the output voltage can be either single-phase or three-phase. More efficient three-phase versions are rated at 380 volts, single-phase at 220 volts. Mobile diesel generators are available in power ratings from 1.5 to 20 kW. Industrial - from 20 to 100 kW or more.

Wow, I'd employ this type of machine while doing some of my home work. Although, I still dont know how to use it fully. Lol

Nice post