History of mirror

Left: Bronze mirror, New Kingdom of Egypt, Eighteenth Dynasty, 1540–1296 BC

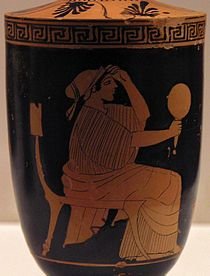

Right: seated woman holding a mirror; Ancient Greek Attic red-figure lekythos, c. 470–460 BC, National Archaeological Museum, Athens, Greece

Roman fresco of a woman fixing her hair using a mirror, from Stabiae, Italy, 1st century AD

Adorning Oneself', detail from 'Admonitions of the Instructress to the Palace Ladies', Tang dynasty copy of an original by Chinese painter Gu Kaizhi, c. 344–405 AD

A sculpture of a lady looking into a mirror, from Halebidu, India, 12th century

The first mirrors used by humans were most likely pools of dark, still water, or water collected in a primitive vessel of some sort. The requirements for making a good mirror are a surface with a very high degree of flatness (preferably but not necessarily with high reflectivity), and a surface roughness smaller than the wavelength of the light. The earliest manufactured mirrors were pieces of polished stone such as obsidian, a naturally occurring volcanic glass. Examples of obsidian mirrors found in Anatolia (modern-day Turkey) have been dated to around 6000 B.C.[3] Mirrors of polished copper were crafted in Mesopotamia from 4000 B.C.,[3] and in ancient Egypt from around 3000 B.C.[4] Polished stone mirrors from Central and South America date from around 2000 B.C. onwards.[3] In China, bronze mirrors were manufactured from around 2000 B.C.,[5] some of the earliest bronze and copper examples being produced by the Qijia culture. Mirrors made of other metal mixtures (alloys) such as copper and tin speculum metal may have also been produced in China and India.[6] Mirrors of speculum metal or any precious metal were hard to produce and were only owned by the wealthy.[7] These stone and metal mirrors could be made in very large sizes, but were difficult to polish and get perfectly flat; a process that became more difficult with increased size; so they often produced warped or blurred images. Stone mirrors often had poor reflectivity compared to metals, yet metals scratch or tarnish easily, so they frequently needed polishing. Depending upon the color, both often yielded reflections with poor color rendering.[8] The poor image quality of ancient mirrors explains 1 Corinthians 13's reference to seeing "as in a mirror, darkly."

In her history of the mirror, Sabine Melchior-Bonnet draws significant attention to the relation of the mirror to Greek philosophy, specifically Socrates:

If well used, however, the mirror can aid moral meditation between man and himself. Socrates, we are told by Diogenes, urged young people to look at themselves in mirrors so that, if they were beautiful, they would become worthy of their beauty, and if they were ugly, they would know how to hide their disgrace through learning. The mirror, a tool by which to "know thyself," invited man to not mistake himself for God, to avoid pride by knowing his limits, and to improve himself. His was thus not a passive mirror of imitation but an active mirror of transformation. (p.106)[9]

Glass was a desirable material for mirrors. Because the surface of glass is naturally smooth, it produces reflections with very little blur. In addition, glass is very hard and scratch-resistant. However, glass by itself has little reflectivity, so people began coating it with metals to increase the reflectivity. Metal-coated glass mirrors are said by the Roman scholar Pliny the Elder to have been invented in Sidon (modern-day Lebanon) in the first century A.D., although no archeological evidence of them date from before the third century.[10] According to Pliny, the people of Sidon developed a technique for creating crude mirrors by coating blown glass with molten lead.[11][12] Glass mirrors backed with gold leaf are mentioned by Pliny in his Natural History, written in about 77 A.D.[13] Because there were few ways to make a smooth piece of glass with a uniform thickness, these ancient glass-mirrors were made by blowing a glass bubble, and then cutting off a small, circular section, producing mirrors that were either concave or convex. These circular mirrors were typically small, from only a fraction of an inch to as much as eight inches in diameter.[14] These small mirrors produced distorted images, yet were prized objects of high value. These ancient glass mirrors were very thin, thus very fragile, because the glass needed to be extremely thin to prevent cracking when coated with a hot, molten metal. Due to the poor quality, high cost, and small size of these ancient glass mirrors, solid metal-mirrors primarily of steel were usually preferred until the late nineteenth century.[15]

Parabolic mirrors were described and studied in classical antiquity by the mathematician Diocles in his work On Burning Mirrors.[16] Ptolemy conducted a number of experiments with curved polished iron mirrors,[17] and discussed plane, convex spherical, and concave spherical mirrors in his Optics.[18] Parabolic mirrors were also described by the physicist Ibn Sahl in the tenth century,[19] and Ibn al-Haytham discussed concave and convex mirrors in both cylindrical and spherical geometries,[20] carried out a number of experiments with mirrors, and solved the problem of finding the point on a convex mirror at which a ray coming from one point is reflected to another point.[21] By the 11th century, glass mirrors were being produced in Moorish Spain.[22]

In China, people began making mirrors by coating metallic objects with silver-mercury amalgams as early as 500 A.D. This was accomplished by coating the mirror with the amalgam, and then heating it until the mercury boiled away, leaving only the silver behind.[23]

The problems of making metal-coated, glass mirrors was due to the difficulties in making glass that was very clear, as most ancient glass was tinted green with iron. This was overcome when people began mixing soda, limestone, potash, manganese, and fern ashes with the glass. There was also no way for the ancients to make flat panes of glass with uniform thicknesses. The earliest methods for producing glass panes began in France, when people began blowing glass bubbles, and then spinning them rapidly to flatten them out into plates from which pieces could be cut. However, these pieces were still not uniform in thickness, so produced distorted images as well. A better method was to blow a cylinder of glass, cut off the ends, slice it down the center, and unroll it onto a flat hearth. This method produced the first mirror-quality glass panes, but it was very difficult and resulted in a lot of breakage. Even windows were primarily made of oiled paper or stained glass, until the mid-nineteenth century, due to the high cost of making clear, flat panes of glass.[24]

The method of making flat panes of clear glass from blown cylinders began in Germany and evolved through the Middle Ages, until being perfected by the Venetians in the sixteenth century. The Venetians began using lead glass for its crystal-clarity and its easier workability. Some time during the early Renaissance, European manufacturers perfected a superior method of coating glass with a tin-mercury amalgam, producing an amorphous coating with better reflectivity than crystalline metals and causing little thermal shock to the glass.[25] The exact date and location of the discovery is unknown, but in the sixteenth century, Venice, a city famed for its glass-making expertise, became a center of mirror production using this new technique. Glass mirrors from this period were extremely expensive luxuries.[26] For example, in the late seventeenth century, the Countess de Fiesque was reported to have traded an entire wheat farm for a mirror, considering it a bargain. These Venetian mirrors were limited in size to a maximum area of around 40 inches (100 cm) square, until modern glass panes began to be produced during the Industrial Revolution.[27] The Saint-Gobain factory, founded by royal initiative in France, was an important manufacturer, and Bohemian and German glass, often rather cheaper, was also important.

The invention of the silvered-glass mirror is credited to German chemist Justus von Liebig in 1835.[28] His process involved the deposition of a thin layer of metallic silver onto glass through the chemical reduction of silver nitrate. This silvering process was adapted for mass manufacturing and led to the greater availability of affordable mirrors. In the modern age, mirrors are often produced by the wet deposition of silver, or sometimes nickel or chromium (the latter used most often in automotive mirrors) via electroplating directly onto the glass substrate.[29]

Vacuum deposition began with the study of the sputtering phenomenon during the 1920s and 1930s, which was a common problem in lighting in which metal ejected from the electrodes coated the glass, blocking output. However, turning sputtering into a reliable method of coating a mirror did not occur until the invention of semiconductors in the 1970s. Evaporation coating was pioneered by John Strong in 1912. Aluminum was a desirable material for mirrors, but was too dangerous to apply with electroplating. Strong used evaporation coating to make the first aluminum telescope mirrors in the 1930s.[30] The first dielectric mirror was created in 1937 by Auwarter using evaporated rhodium, while the first metallic mirror to be enhanced with a dielectric coating of silicon dioxide was created by Hass the same year. In 1939 at the Schott Glass company, Walter Geffcken invented the first dielectric mirrors to use multilayer coatings (stacks).[31]

.jpg)

Congratulations @raees786! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOP