Drifting fish feed making device Line

The technological advantages attained by RICHI's efforts in drifting fish feed making makers over the years are fully shown in the drifting fish feed production line.

Simple procedure, very easy to learn, specific criterion control, to make sure that the product is finished in a specific temperature level, stress, humidity and time.

Practical framework style, special material, quick self-cleaning efficiency to make certain mechanical security and also very easy upkeep, vivid forms as well as tastes to meet the needs of different fish family pet food.

Related post: floating fish feed pellet making machine

When choosing aquafeed drifting fish feed assembly line, you need to first understand the many attributes of aquafeed:

( 1 )Small pellet size. Due to the brief gastrointestinal system of aquatic pets and related physical qualities, in order to quicken food digestion as well as absorption, the crushed pellet size of water feed ought to be smaller sized than that of animals and poultry feed.

For example, in the manufacturing of eel and shrimp feed, the pellet dimension must get to 80 mesh to 120 mesh.

( 2) High protein web content and low carb content. The protein content of livestock as well as poultry feeds is normally less than 20%, while the protein content of aquatic animal feeds is mostly 30% to 40%, and also the healthy protein content of turtle as well as eel feeds is as high as 65% to 70%.

( 3) The pellet feed has a small framework, high cohesion and also water resistance, and also the stability of the pellet feed in water for more than 2 hours is needed for fish feed.

( 4) In the manufacturing of water feed, cross-contamination is strictly forbidden. Some resources require to be dealt with aseptically.

The picked drifting fish feed making maker is easy to tidy and also has much less residue. Especially in the production of drifting feed, shrimp and eel feed, other kinds of feed should not be generated at the same time to prevent cross-production pollution.

To create premium aquatic feed, we should rely upon scientific and also sensible handling technology and also incorporate it with progressed, reputable and secure floating fish feed making maker. Hereof, the selection of floating fish feed making device is particularly important.

- Process flow of fish feed production line:.

The drifting fish feed making equipment production line can process pellet feeds such as pigs, cattle, lamb, bunnies, poultries, ducks, fish, etc. The conventional handling technique is a number of times more effective, as well as it appropriates for massive farms and drifting fish feed mills to produce full-price feed and the improvement of pellet feed plants.

It can also generate saw wood pellets, timber powder pellets and also straw pellets, and so on. It is a pellet handling device with a high degree of automation. It is a drifting fish feed making device that uses corn, soybean dish, wheat, sorghum, straw, turf, rice husk, etc as basic materials, squashes the raw materials, and straight presses them right into pellets.

Related post: https://aquafeedmachine.com/floating-fish-feed-pellet-making-machine/

- Features of fish feed pellet device assembly line:.

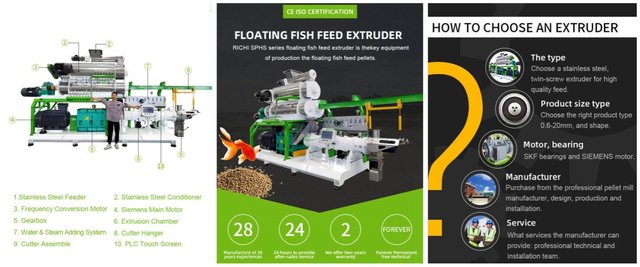

① This series of floating fish feed making devices embrace a heavy steam conditioner, so that the product can be completely matured and the top quality of the pellets can be guaranteed.

② The primary drive adopts high-precision equipment drive, and also the output has to do with 20% higher than that of the belt drive kind.

③ Imported high-quality bearings and also oil seals are chosen to guarantee secure operation, low noise and also high performance of the whole equipment.

④ The feeder adopts regularity conversion electric motor to make certain the high quality of pellet discharge.

⑤ A variety of aperture ring dies are available for selection. The drifting fish feed making machine ring dies have lengthy service life, smooth granulation and premium quality.

⑥ Settlement kind serpentine spring combining of global advanced degree, with unique framework, compactness, safety, reduced noise and low failing performance.

- Drifting fish feed device assembly line procedure.

Drifting fish feed making machine is usually picked according to the manufacturing scale, production ranges, and also manufacturing process problems. As a result, different floating fish feed mills commonly make use of various devices. Nevertheless, some basic floating fish feed making equipment for feed processing is the same.

According to the floating fish feed making maker line procedure flow, it usually includes basic material obtaining and also cleaning up devices, sharing tools, squashing devices, batching equipment, mixing equipment, drifting pellet machine, drifting fish feed extruder machine, liquid splashing devices, ventilation and dirt elimination equipment, packaging tools as well as main control system.

The raw product getting and also cleaning devices primarily consists of weighbridges, main cleaning displays and cylinder containers;.

Frequently made use of communicating equipment are screw conveyors, bucket elevators, scraper conveyors, belt conveyors and pneumatic conveying tools;.

Pulverizing equipment includes magnetic separator, feeder, pulverizer, etc. Amongst them, there are several types of pulverizers, generally made use of are hammer and claw pulverizers and also mini pulverizers that need finer pulverization;.

The batching tools typically embraces digital automatic batching scales; the types of mixers made use of are horizontal double-shaft (single-shaft) paddle mixers, straight screw mixers, vertical mixers as well as waist drum mixers for the production of premixes;.

Granulation equipment includes vapor boiler, conditioner, floating fish feed pellet mill, cooler, rating display as well as crusher, etc;.

Floating fish feed extruder device includes conditioner and also extruder; liquid spraying tools includes liquid tank, vacuum pump as well as circulation meter;.

Air flow as well as dust removal equipment includes suction followers, brakes and also dirt collection agencies, and so on; product packaging devices includes packaging scales, securing equipments, etc;.

The main control system is the "brain" of the whole drifting fish feed making equipment line handling procedure, where the control systems of various equipment are concentrated.

Related post: Feed mill factory in Russia

- Quality control of floating fish feed making device.

( 1 ) Tools pre-design control.

The technical personnel will certainly accomplish scientific as well as affordable design according to the real conditions as well as requirements of the consumer's workshop, electrical energy, location, and so on, incorporated with the floating fish feed making device examination situation.

( 2 ) Spare parts option standards.

Spare components vendors, strictly screen the provider's products, and pick top quality and also affordable suppliers in the same sector. On the facility of guaranteeing high quality, reduce floating fish feed making equipment manufacturing costs and also genuinely allow consumers to purchase affordable devices. For outsourced parts of the exact same range, there are less than three providers ensured, so that the fittest can be purchased.

( 3 ) Production control.

After the sales department obtains the order, it will be submitted to the technological department, as well as the technical division will produce the CAD illustrations corresponding to the floating fish feed making device according to the order information. The production department sets up a appropriate component to acquire, produce and process according to the technological documents of CAD drawings.

( 4 ) Devices and also extra parts approval.

There are full time quality control employees to execute batch assessment of outsourcing and also outsourcing components. Quality assessment is done for key as well as specific spare components. For self-made components, self-inspection, common examination and also general assessment of handling workers must be carried out, and all qualified components can be taken into usage.

After the completed floating fish feed making machine is installed, it will certainly be accepted by after-sales service technicians. On-site equipment can be loaded for on-site debugging just after no-load procedure for over half an hr and also no mistakes. See to it that each equipment fulfills the drifting fish feed mill manufacturing facility conditions and issue the drifting fish feed making maker certificate.

For details please contact: feed machine

WhatsApp:86 138 3838 9622

Email:[email protected]