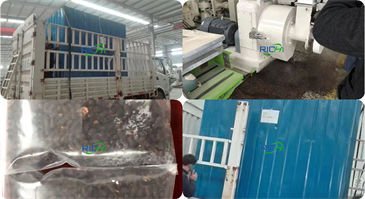

Assembly line of natural plant food pellet making equipment

The natural plant food device is composed of organic fertilizer fermentation turner, plant food pulverizer, mixer, natural plant food pellet making device, natural plant food clothes dryer, cooler, screening maker, storage container, automated packaging device, belt conveyor, and so on.

Handling animals and also fowl manure, straw rice husks, biogas sludge, cooking area waste, community waste as well as various other natural materials into organic plant foods can not just lower environmental pollution however additionally transform waste right into treasure.

Related post: pellet making machine

1. Refine circulation of organic plant food pellet making maker line

① After the fermentation of the natural fertilizer raw materials is completed, it goes into the organic fertilizer pulverizer as well as is pulverized into powder. The powder goes into the organic fertilizer mixer as well as adds supporting materials for stirring.

After mixing evenly, it gets in the organic plant food pellet making maker to make granules, and the produced granules are dried out. The dampness of the bits is decreased to 10-20% in the machine, and then goes into the air conditioning maker for air conditioning.

After cooling, it gets in the screening machine for testing, and the unqualified items are screened as well as come back right into the pulverizer by the return belt conveyor to be squashed, and screened out. The finished product can be packaged straight.

② The treated livestock manure is straight carried to the raw material silo (or raw material mixer);.

③ The animals manure is transported to the disc homogenizer as well as uniformly contributed to the rotating disc of the disc organic fertilizer pellet making machine; the fluid component or an proper quantity of water is sprinkled on the fluid element distributor of the disc natural plant food pellet making device.

The product in the disc can meet the fluid stage needed for round formation; the turning disc and also the edge of the disc create friction and also centrifugal impact on the material, to ensure that the material can move in a circumferential direction, and the powder bits can be massaged as well as pressed versus each other.

https://www.richipelletmachine.com/organic-fertilizer-pellet-making-machine/

Because of the difference in bit mass, the resulting gravitational and centrifugal impacts are not the same. When the gravitational as well as centrifugal results are raised sufficient to conquer the rubbing in between fragments, they will be tossed out of the disc. Tiny particles still remain in the disc and remain to agglomerate great fragments;.

④ Transport to the natural plant food clothes dryer, as well as exchange warm with the heat from the hot blast oven;.

⑤ The pellets are transferred to the warm testing for sorting, as well as the great particles are directly gone back to the disc organic fertilizer pellet making machine, as the core to remain to join the bond of the particles into balls;.

⑥ Transport to the natural plant food colder, as well as cool down the plant food by all-natural cold air or compelled chilly air;.

⑦ Transported to the ended up product testing maker, the large particles are crushed by the pulverizer and also returned to the disc homogenizer to remain to participate in ball development;.

⑧ The certified products after evaluating are sent out to the coating maker for finishing therapy;.

⑨ Transportation to automatic product packaging range for weighing, packaging as well as storage;.

⑩ Drying, cooling as well as workshop dirt are left as much as the requirement after three-stage therapy by cyclone dust collector, maze dust elimination chamber as well as wet washing.

2. Benefits of making manure pellets.

The manufacturing of animals manure natural fertilizer by granulation procedure has the following advantages:.

( 1) The operation is instinctive, and also the procedure of the natural plant food pellet making device can be understood at any time. If it is located to be uncommon, it can be readjusted in time;.

( 2) The dimension of the fragments is established by the disposition angle and turning rate of the disc, and also the inclination price and also turning speed of the disc can be readjusted. Therefore, the disc organic plant food pellet making device granulation procedure has a broad control variety for particle dimension, strong flexibility, and a extremely high spheroidization rate., can get to 70% ~ 90%;.

( 3) The organic plant food pellet making maker manufacturing process of the chicken manure natural plant food is short, the framework is easy, the investment is low, and the operation is very easy, which is preferable for little and medium-sized enterprises.

The natural fertilizer pellet making maker is lined with polypropylene polymer smooth plastic plate, which is challenging to stay with the wall surface. It is suitable for the annual output of more than 100,000 to 300,000 lots. It has steam problems for nitro as well as urea thaw spray granulation as well as water spray granulation.

Compound fertilizer granulation is a procedure in which standard fertilizer is blended and also granulated with a drum natural plant food pellet making machine as the core equipment; the mixed acid as well as artificial ammonia are reacted in a tubular reactor in proportion to produce substance plant food slurry which is directly sprayed right into the drum for granulation.

A certain proportion of nitrogen, phosphorus and potassium is generated in the organic plant food pellet mill to produce a sulfur-based compound plant food. The product has the features of consistent granulation, bright color, steady high quality, sufficient nutrients, simple to liquify and be absorbed by crops, etc, specifically as seed fertilizer is fairly risk-free. Appropriate for all kinds of dirt and also plants.

Richi Machinery is a assigned maker of natural plant food pellet making maker marked by the Green Development Committee, with a plant location of 39,800 square meters. Our business has solid technical pressure, high-grade staff as well as CAD design center, as well as has been committed to the research, production and development of natural fertilizer tools and also substance BB fertilizer devices for a very long time.

Provide new and also old clients with comprehensive solutions of organic fertilizer pellet making machine assembly line procedure design, equipment manufacturing, setup and appointing, and formula one-stop solution. The products cover all parts of the country and also are exported to South Africa and also Southeast Asian countries.

For details please contact: Richi Machinery

WhatsApp:86 138 3838 9622

Email:[email protected]