Toilet Paper

My Dear Steemit Friends, right now I want to talk with you, very briefly, about another friend that is always in our homes, I mean toilet paper. The objective is introduce you, very visually how to produce a roll of toilet paper. The process begins with large rolls of paper, which are produced at industrial level, which then we will review in another publication.

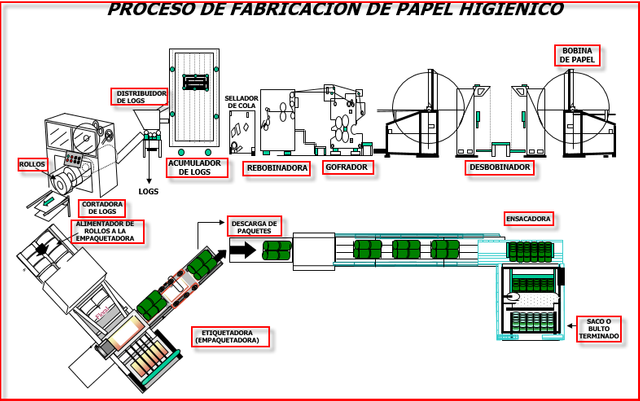

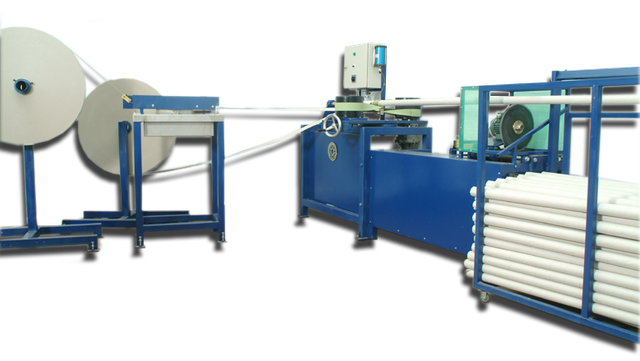

These large paper rolls feeding to the production process of a conversion plant or paper manufacturer tualé. In general terms, the process can be visualized as follows::

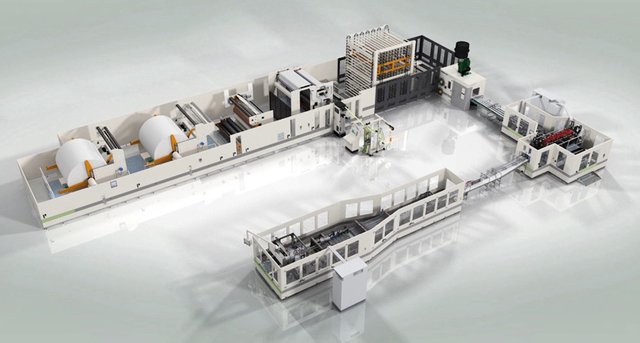

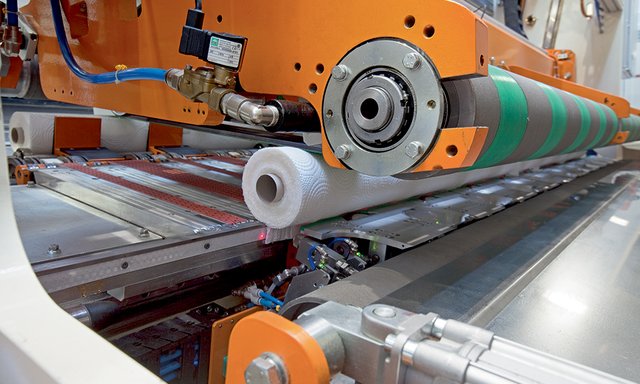

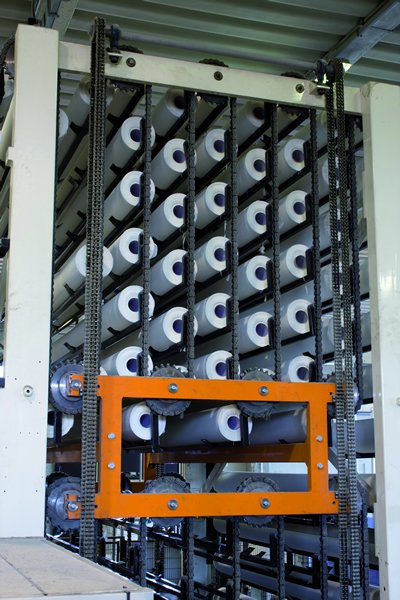

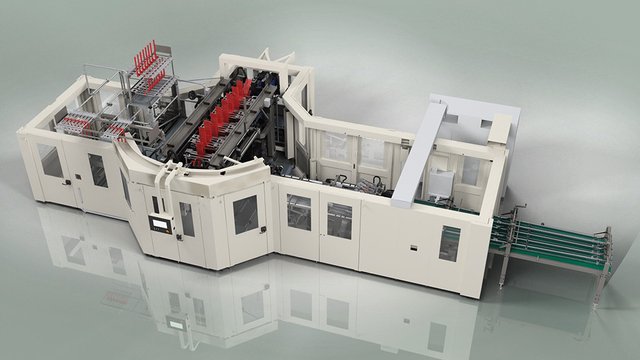

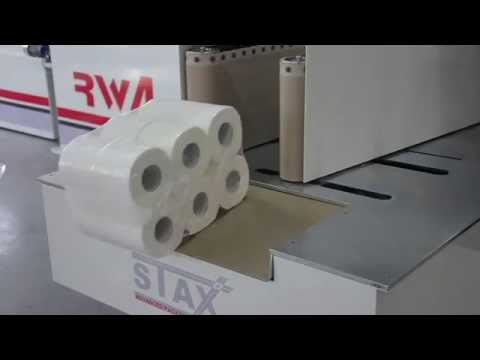

Drawing of my authorship made in Power Point. In photo it would be something like this:: We start with big rolls of toilet paper (called parent rolls which are industrial production), which are manufactured in paper machines (this other great process that we will be reviewing in another post). These parent rolls are mounted on the unwinders (desbobinadores in spanish), of the converting line:: View of the parent rolls mounted on the unwinders where they will begin to unwind. It is like a large spool of thread that will begin to unwinding From the unwinders, the unrolling paper will now go through an engraving system called embosser system, whose function is simply to make an engraving or marks on paper. Note: Many papers are not engraved, they are plain without engraving: If we follow the initial general diagram, we will see that the paper that is unrolling will go to the section of the rewinder. Here the paper will be transformed into a kind of paper logs, of low diameter (usually between 108 and 120 mm in diameter), with a previously defined footage (in our country the standard footage has usually been over 30 meters although you can get them different footage) and with a width that is equal to the width of the parent roll that was mounted on the unwinders (note: each paper log will subsequently give rise to a specific number of rolls, for example if a log of 262 centimeters in width was produced and each toilet roll to be produced is going to have 10 centimeters high, then 25 rolls per log must be produced, considering that a % of the log is lost as waste in the process). In the rewinder, by means of a roller system with installed blades, the perforations are made on the paper, which is where we normally cut it when we use it: Already here the LOG comes perforated, with the required footage and goes to a station known as a tail sealer, where a special glue is simply placed on the end of the paper so that it sticks to the log. This is the adhesion that we remove when we are going to proceed to use the roll in our bathrooms. LOG leaving of the Rewinder- Note: the log is like a roll of toilet paper but very long; It still needs to be cut into rolls. Log is entering to the tail sealer system. Then the LOG leaves the tail sealer and it is going to enter to the Log Accumulator (It's a stock of logs in vertical arrangement): View of the log accumulator. The quantity of logs can vary in each machine: 100, 200 or more logs. Then the process continue at the log saw, here we cut each log to a specific number of small rolls de toilet paper: Now the small rolls (toilet paper), leave the log saw and they going to enter to the wrapping machine. Of course between log saw and the wrapping machine we use a conveyor: . The small rolls entering to the wrapping machine. General view of the a wrapping machine. In the wrapping machine the small rolls will be wrapping with plastic in diferents configurations: two, four, six, eight, twelve small rolls or more.: Plastic package is sealed with heat in a system of thermic belts. Now the packages of rolls leave the wrapping machine and ther are going to enter to the bundler or baler(ensacadora in spanish): Now the packages are ordered in groups of two, four, six, eight, etc, at the feeding system of the bundler. At the end of this process we will have a bigger package, wraps in plastic, with more rolls per bale.: Bale of toilet paper leaving the bundler or baler. Ah by the way, the core (cardboard tube) of the small of toilet paper is produced in a equipment off machine. This core was incorporated to the LOG in the rewinder process: With this we conclude this quick and general overview of the production process of the toilet paper, hoping that you have been able to learn something new from this famous companion that it does not lack in our homes. The objective is posting more information like this. Greetings Carlos J.

I thought this would be some kind of joke when i clicked it. But is really interesting to read about toilet paper. I thought the paper would be cut first and then rolled. I really learned someting today. Thank you for your clear explanation.

It's good that you liked it and that you learned. Greetings

Muy buena publicación, es increíble ver el proceso de producción de algo que usamos a diario y a veces no tomamos por importante su elaboración. Gracias por presentarnos esta publicación.

Very good publication, it is amazing to see the production process of something that we use every day and sometimes we do not consider it important. Thank you for submitting this publication.

Gracias por la buena valoraciòn del post y que te haya gustado el proceso; es solo parte breve de lo que implica convertir y producir papel. Saludos.

No hay nada que agradecer! El trabajo y la dedicación para hacer un post así se valora, lastima que mi poder de voto sea nada, sino la historia seria otra!