A Quick Lesson on Pumping

How to Size a Pump - 101

AKA - Learning to Defy Gravity

I keep meaning to practice a little bit of writing the last few weeks here, because it's dreadfully quiet out here on the blockchain. However, I couldn't think of anything interesting or entertaining to write about -- been bogged down by the rain quite a bit. So -- considering that I've been working so much the last few weeks, it made sense to me that I should write a little bit about work.

Those of you that know me are probably aware that my day job is pretending to know what I'm doing as a civil engineer in Canada. This is, more or less, a fancy way to say that I make water go downhill in an orderly fashion. I deal with design of sewer systems (storm / sanitary), water distribution networks, water treatment, waste water treatment, stormwater treatment, municipal services, road design, and all the construction that follows. Generally -- If you live in a City with people in it, there's engineers like myself to blame for everything bad that has ever happened to you.

So here's a brief lesson on how to size a pump to move water from A to B. As said before, step #1 is making sure that point B is at a higher elevation than point A. Otherwise, you're dumb.

Find your Static Head:

- Static head or Static "Pressure" head, is pretty much just the "height" or "column" of water you have to pump through. Water is interesting in that, if you have a pool with 1.5m (this post will be using metric, btw) of water in it, you'll have a 'pressure head' of 1.5m exerted on the bottom of the pool. It doesn't matter if it's a backyard sized pool, or an olympic sized pool. All that matters is the HEIGHT of water within.

- Therefore, the static head that you need to overcome is simply the elevation of point B minus elevation at point A.

- ZB - ZA;

- Lets keep it simple and assume we're going from 0m -> 10m -- so our static head is 10m;

Determine your "System Curve":

- As water travels through a pipe, it come into contact with the inside walls of the pipe. Considering that we haven't invented frictionless pipes yet, we accrue friction losses in the pipe, which reduces the internal pressure head along the length of our pumping route;

- Obviously, we need to understand how much "friction loss" we need to overcome over the length of our pumping route:

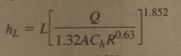

- Because I can't be bothered to write a nicely formatted equation -- here's a photo from a reference book I have:

- HL = HeadLoss in the system (m);

- L is the length of our pumping route (m);

- Q is the flow rate (m3/s);

- Ch is a unitless friction factor specific to the type of pipe material we're using. In this case, we'll use HDPE w/ a C factor of ~110;

- R is the "Hydraulic Radius" of our pipe, which is defined as the cross sectional area of our pipe, divided by the wet perimeter. This is an easy calc for full pipes, but gets more complicated for non-pressurized systems or irregular cross section pipes.

- --> R = A/Wp = (πR2)/(2πR) = R/2

So lets assume:

- L = 1000m;

- Q will vary for each calculation to make our chart; and

- we're using a 450mm pipe

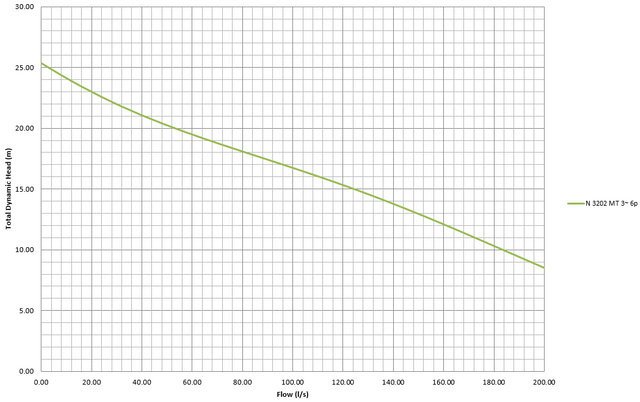

Plugging that gnarly mathy business above into a spreadsheet gives us what we in the biz like to call a "System Curve". This is fancy talk for "a line that shows headlosses, through the pipe, at different flow-rates". Check out the image below:

You can see that we're STARTING at 10m of head, which is the same as our "Static Head" that we need to overcome. As we push higher and higher flow-rates through our pipe, we realize more friction losses, and we increase the total head we have to overcome in our system. We're getting close now.

- Check out some pump curves from various manufactures:

- This is where stuff gets a bit finnicky or frustrating. This generally boils down to reaching out to a pump manufacturer with a lot of the information we've discussed above. OR;

- You can do some background research and find the pump-curve for various models, which are typically listed on a manufacturers website;

- One of the suppliers we typically like to use (because they make high quality pumps) is Flygt. I think they're originally from Norway (could be way off), but they supply pumps globally -- and they've got some really smart guys in Vancouver that deal with a lot of the pump-specific stuff that I don't know how to do (I'm not a mechanical engineer);

- So for example, we can look at the pump curve for Flygt's "N 3202 MT3 - 26kW power" pump:

- This looks similar to our last graph, but going in the other direction.. "What is this telling me?", an astute reader may be asking.

- Generally, the pump curve can be described as "How much flow a pump can produce, as it pumps against a specfic amount of pressure head".

- You can see the starting point or "shutoff head", is a little over 25m. That means that this pump wont be able to move any fluid if it's facing more than 25m of pressure head.

- As the head it's pumping against decreases, it can move more and more fluid through the pipes.

Only now, dear pump-aholic, are we able to see how this pump will operate in our system:

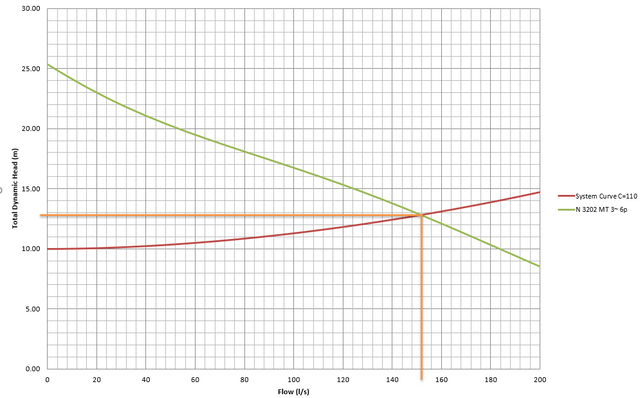

- If we put both of the above curves onto the same graph, we can find the "duty point" of our system, which describes how this pump is likely to operate:

Shown above, we can see that this specific pump will likely move about 152L/s against approximately 12.8m of head

This is just a primer (no pun intended) in pump selection, and is by no means all there is to know.

Realistically, there are many things to consider in this process to ensure this pump is suitable...

- Is 152L/s way too much, or not enough flow?;

- Can our pipe withstand 12.8m of pressure head (spoiler alert -- yes it can);

- Are there other pumps elsewhere in the system that this might need to interact with smoothly...;

- How much electricity does this pump consume?;

- What efficiency is the pump running at? Are we wasting some electricity?;

- How much do these pumps cost? Cost we do the same thing with 2 or 3 smaller and cheaper pumps at a more effective cost?;

If you have any questions -- let me know, and I'll see if I can answer them.

I'm considering writing some more basic engineering / math-y / coding / science-y posts -- so hold on to your butts, and try to enjoy things.

This post has been voted on by the SteemSTEM curation team and voting trail in collaboration with @curie.

If you appreciate the work we are doing then consider voting both projects for witness by selecting stem.witness and curie!

For additional information please join us on the SteemSTEM discord and to get to know the rest of the community!