How to get Steel from Iron ore

“If you wish to make an apple pie from scratch, you must first invent the universe.”

― Carl Sagan, Cosmos

The Iron Rolling Mill (Eisenwalzwerk), 1870s, by Adolph Menzel. Source

In the last article the advantages of steel where presented. But how do you get steel from iron ore? That will be shown here.

Ways to get Steel

Steel is made by smelting iron: During this process other elements are added or taken away from the alloy to get the needed steel. It is then casted into form for further processing.

Smelting Ore

Smelting iron ore has a long tradition. The right material had to be found. Iron ore can be mined and partly found outside.

The iron ore is heated in the smelter until it melts; the heavier iron will separate from the other components by gathering in the bottom of the furnace. This process needs time, because the metal must get to the right temperature and then drip through all the other layers. The process can be speed up by increasing the purity of the iron ore and choosing more optimal ways to heat the metal.

As an example: A crude way to heat the smelter is using coal, on which the iron ore is stacked. The iron now has to flow through the still solid ore components AND the coal.

There are several ways to heat the furnace:

- Fire: Mostly by firing with coal, coke, gas or what else is available.

- Electricity: An electrode is introduced into the ore and runs high enough currents through it to melt it.

- Microwave: Microwaves energy can be used for smelting, but is mainly used for artesanal gold smelting because of the small amount.

Simple Fire

The oldest and still reliable method of heating the steel with burning coal, coke, oil or gas is also very reliable. The fuel can be transported to the steel mill and stored in sufficient amounts to guarantee an interruption free operation.

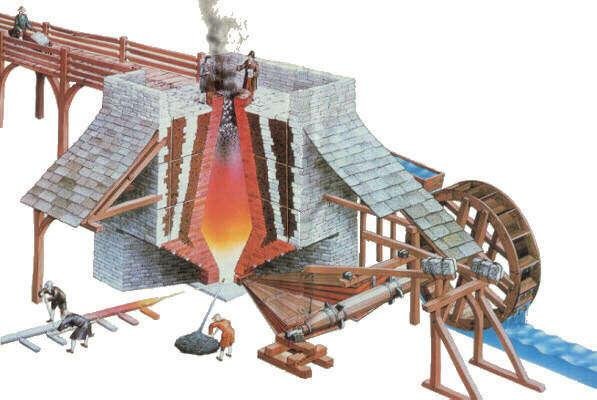

An old design of a blast smelter that burns coal and rises the temperature by blowing air trough it. Source

The heating of the material is done through convection, so transfer of molecule movement to another neighboring molecule. This means that the heat travels slowly from the outside to the inside of the material. This takes time and can lead to an inhomogeneous heating process.

Electric Arc Furnace (EAF)

A beautiful steel mill producing new metal from scrap with an EAF.

The smelting with pure electric power is possible with energy being cheap and abundant. The smelting with an EAF takes less time than with conventional techniques due to the high temperatures of the arc. The process slowly consumes the electrodes.

The arc is produced by graphite electrodes and is many thousand °C hot. A homemade version was even used to melt stones in a couple of minutes.

A variant is a plasma arc furnace, which is used mainly in the titanium melting industry.

Induction Furnace

A small furnace, but the big ones work in the same way.

An induction furnace melts the metal by generating a changing, magnetic field. This creates a changing strong current inside the conducting metal in the furnace, which heats it to the desired temperature. The benefit is that the complete material is heated up at the same time. This makes it very efficient and fast.

Microwave Radiation

A repurposed microwave. Source

While it is not used for industrial steel production, it is possible to use microwaves to heat metals over 3000°C. Hobby gold diggers repurpose microwaves to smelt their findings into bars. Like an EAF it is relatively quick and efficient, but like the induction furnace it is still a little bit faster because it heats the complete material at the same time.

There also exist industrial microwave ovens for smelting, but they have only a small market size.

Smelting Treatments

To reach the desired alloy and not only a piece of metal, smelting involves the following tools:

- Roasting: Heating the ore at "lower" temperatures of a few hundred degrees to remove unwanted carbon or sulfur, leaving an iron oxide.

- Reduction: This is done to remove the oxide. The metal gets heated in a air-starved furnace, which pulls the oxygen out of the raw metal.

- Fluxes: This can be lime for example, which traps sulfur and carbon dioxide to prevent it from going back into the metal.

After the iron and the desired alloy components are added and molten, the steel can be casted into form and cool down.

Casting

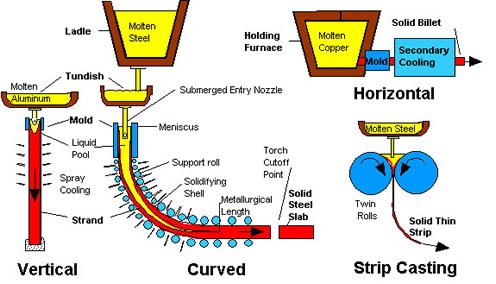

The molten metal is mostly cast into a continuous block which rolled into a desired dimension and either rolled to a coil of sheet metal or cut into pieces for further rolling and forging.

Steel ingot casting. Source

Today approximately 96% of steel is continuously cast, while only 4% is produced as ingots. The reason is that it is a lot easier to directly cast the metal into the production line where it comes out ready to work with at the end. This is also possible with a lot bigger smelters, because the material doesn't need forms to be cast into, but is collected at the end of the production line.

The main benefit of continous casting may be that there is no casting form which needs to cool down.

Continuous casting. Source

The end product can be coils of sheet metal, profiles, rails, or just blocks that are transported to the next production facility.

Recycling

Scrap metal waiting to be recycled. Source

Steel can be smelted again and again as one of the world's most-recycled materials. Over 60% of the steel globally is made through recycling old steel parts. In the United States alone, over 82,000,000 metric tons of steel were made in 2008. In that year it made up 83% of the countries steel production.

But even thought the recycling rate is very high, it can't keep up with the increasing hunger of the industry for more machines, buildings and tools. Thus the mining of steel continues.

Thank you for reading!

If you like this article, I would be very happy if you did me a favor and resteem it!

Follow me also for more on Engineering and Technology.

If you have questions regarding the development of your product, feel free to contact me on: