The Absolute Beginner's Guide to Circuit Board Manufacturing

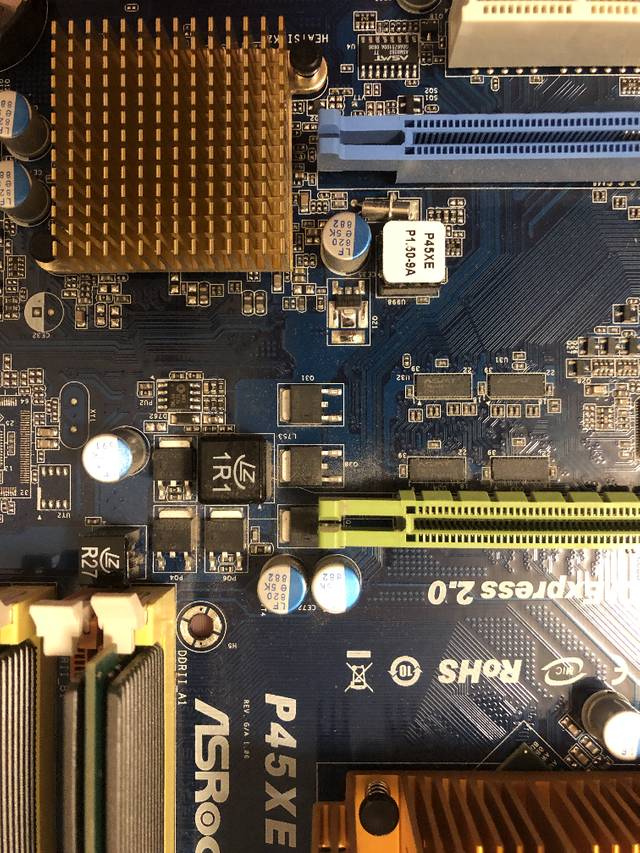

In a former life, I worked in a factory that made circuit boards. You know the things - they're found in every piece of electronics in your house. Here are a couple I found in my own home.

| Remote Control | Motherboard |

|---|---|

|  |

So what exactly does a circuit board do? All by themselves, nothing at all. See how in the pictures there are different components mounted on top of the circuit boards? Those little guys are the brains behind -- er, on top of -- a circuit board. Remember words like "diode", "transistor", and "resistor"? No? Well, no worries. The "stuff" on top of a circuit board is what does all the work.

So, what does a circuit board do?? Well, it connects all the "stuff" that sits on top of it. I like to think of a circuit board as a road network. If we take that analogy, then the "stuff" would be the stores and offices where work gets done, and the cars themselves would be electricity. The roads provide a path for the cars to get to and from offices. The circuit board provides a path for electricity to get to and from the electrical components that do all the work.

You know how you can't stick a fork in a socket without getting a nasty shock? Did you also know that if someone is holding your hand while you do it, they'll get shocked too? Well, that's because electricity is like water in that once it's out of the pipes, it will spread all over until something stops it. Lots of things stop electricity though, like air. But metal won't stop it. So the reason why a circuit board has all kinds of fine lines on it is because the different "streets" that the energy can travel need to be separated from each other. No intersections in this city!

Time for some terrible illustrations to explain things in a bit more detail.

In Theory

Imagine we want to make a simple toy. There are only three pieces to this toy: a power source, a processor, and some memory. We plop them all down on a piece of plastic and now we need to wire them together.

Let's draw some wires to connect all the components. There we go! Whoops, everything is all connected to each other right now, so just like when you stuck the fork in the socket, the moment you turn this toy on, everything will just fry. We need to provide some better paths for the power to take, so it doesn't go all over the place all the time.

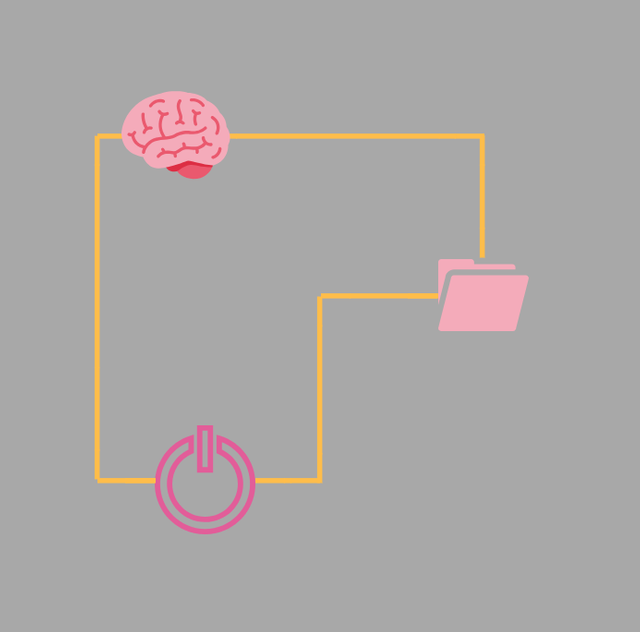

Much better! Now the power has nice insulated pathways to travel between the battery, the processor, and the storage. Well done! But this was grossly simplified; real life is much more complex. Remember my "simple" remote control from the picture above?

So this is a tad more realistic. Lots of bits and pieces here. And they all need to be wired together in just the right way for the electricity to flow properly. This is not unlike how a truck needs to stop at the oil well before it can go to the refinery before it can go to the gas station to drop off gasoline. The power needs to go in a particular order, and since it flows more like water than a smart truck driver, we can only give it one path to choose. So how on earth are we going to find the space on this circuit board to put down that many roads without any of them overlapping? If you tried, it might end up looking something like...

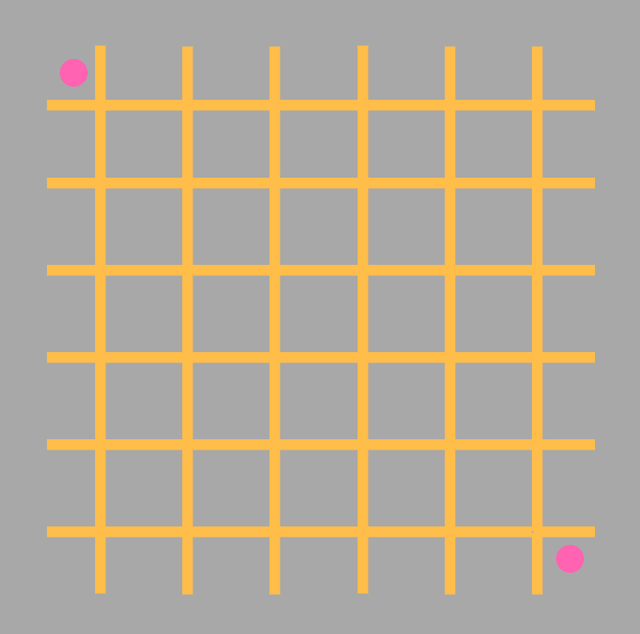

...This mess. Ugh, electricity flying all over the place. If I want to connect the two pink dots, what in the world can I do? Well, think back to our roads in a city example. When the streets get too close together to add another one, what does a city like New York do? They dig. Go underground, and you can fit a whole subway line. Flip over a circuit board, and you'll see paths all over the backside too in all but the most simple examples.

There we go, drilled down one level and now we have a nice clean path that doesn't touch any of the other circuits. If you sandwich three or four of these boards together, you can get really complex networks of circuits inside a very small footprint. But that's getting ahead of ourselves. Let's back up all the way to the beginning again. Since you can't very well draw copper wires onto a circuit board with any degree of precision, speed, or repetition, how can we actually manufacture tons of these things? It all starts with a sheet of copper.

In Practice

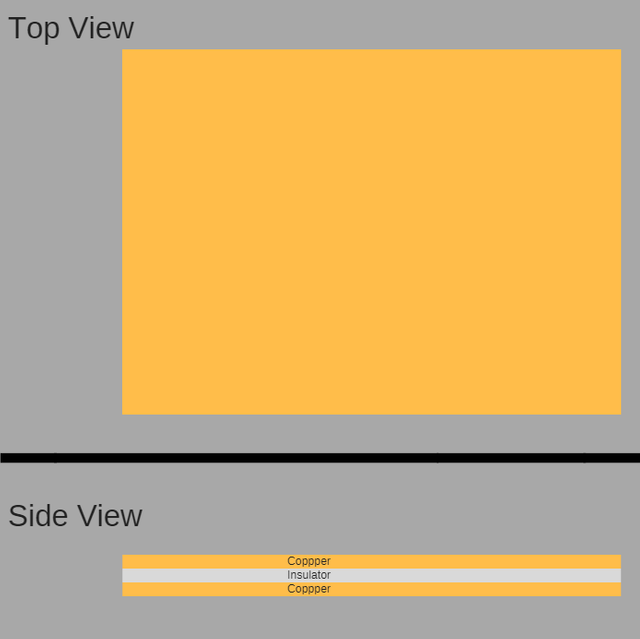

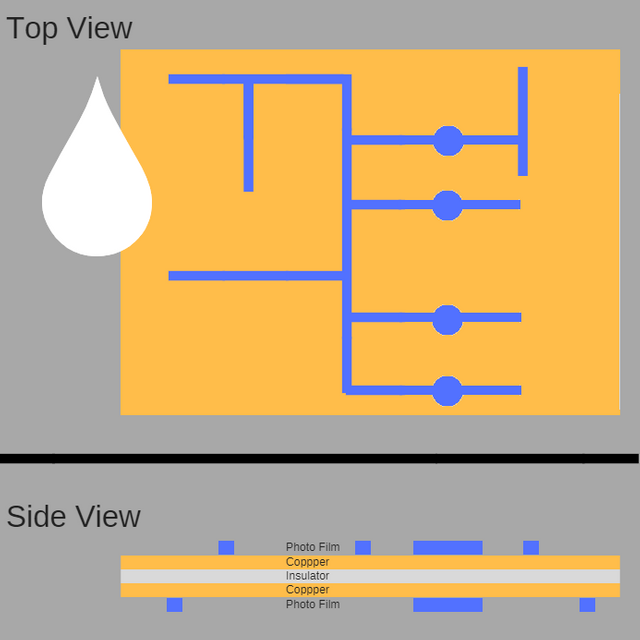

Well, in most cases two sheets of copper sandwiched around a piece of plastic. If you apply electricity to the top side, it won't travel to the bottom side. But the entire top side will be electrified, which does us no good if we want to mount some components. So how do they do it in the real world? The next step is more plastic!

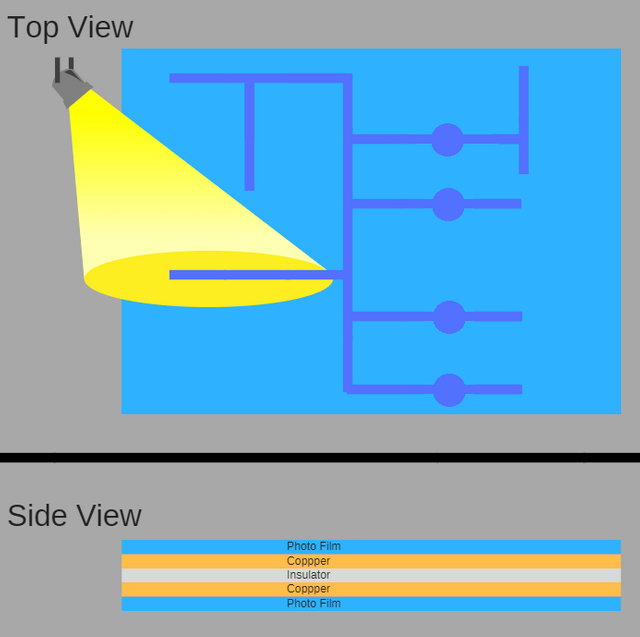

The copper gets covered with a film of photo-sensitive plastic. It sticks to the copper like glue. Then a light or laser gets shined on the film in a particular pattern, either by tracing a shape or by using a stencil that blocks some of the light. Wherever the light hits, the plastic undergoes a chemical reaction and hardens and darkens. When the circuit board comes out the other side, you can see where the circuits are going to be, but there is still a solid sheet of copper under there. Time for the next step.

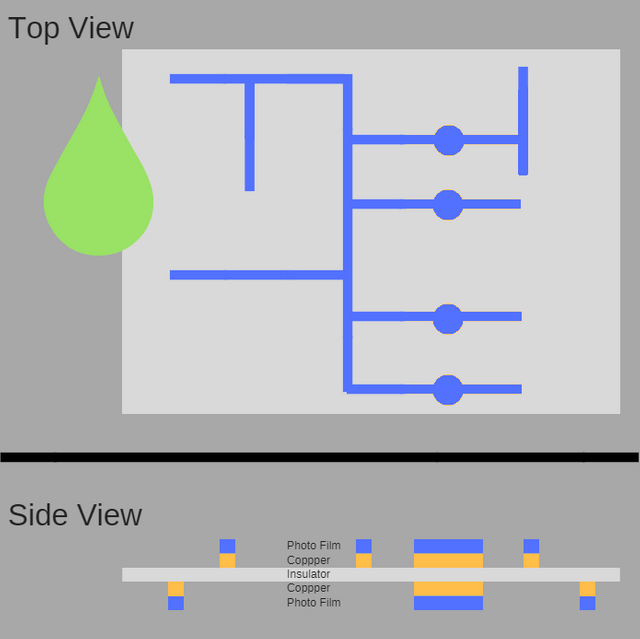

A soapy solvent is used at just the right strength to wash away the film that did not get hardened by the light while leaving behind the rest. Now the only film remaining is on top of where we want the circuits to be, but we still have a solid sheet of copper. So how do we get those circuits? More chemicals!

Remember in Breaking Bad when they would dissolve bodies in plastic tubs of acid? That was because the acid wouldn't react with the plastic. So in circuit board manufacturing, we rely on that same property of plastic again. We rinse the board with acid, which eats away at all the exposed copper. However, the copper that still has the blue film on top is protected from the acid and stays behind. When it comes out of the acid shower, you can see the plastic of the core is now exposed, and your circuits are now clearly visible. Time to take the film off!

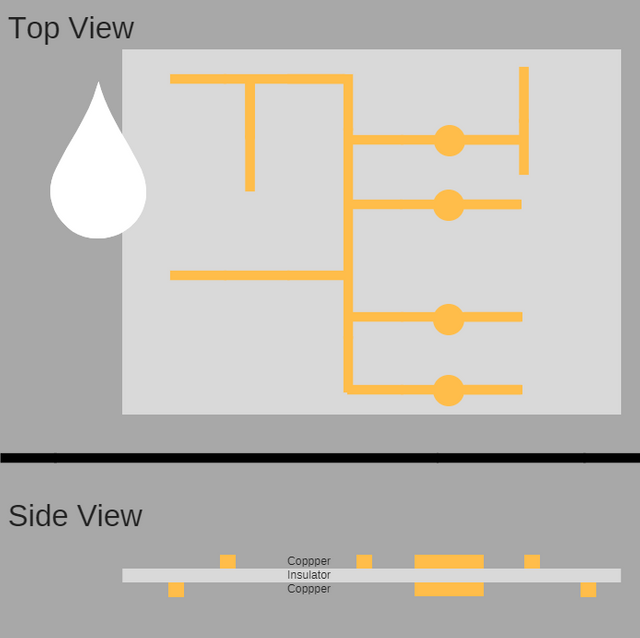

Using a stronger concentration of the solvent from earlier, we wash the rest of the film off. Now you have nice, neat, chemically etched circuits, ready to ferry electricity from point A to point B! But we wanted to make use of more than one layer, so for today there is one more step.

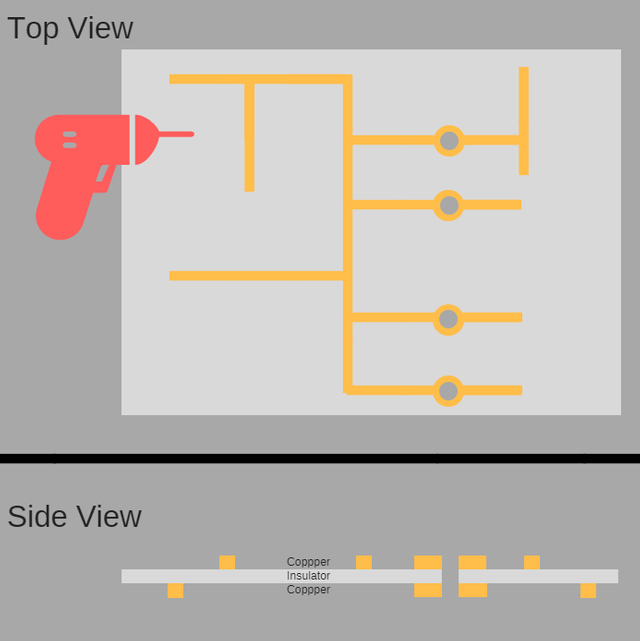

We drill a literal hole through the copper pads to join the layers together. Think of this like a subway station. People can get in at street level, and head down to get on a metro train. Then they travel somewhere else and pop back up again. Same principle at work on your circuit board!

In Closing

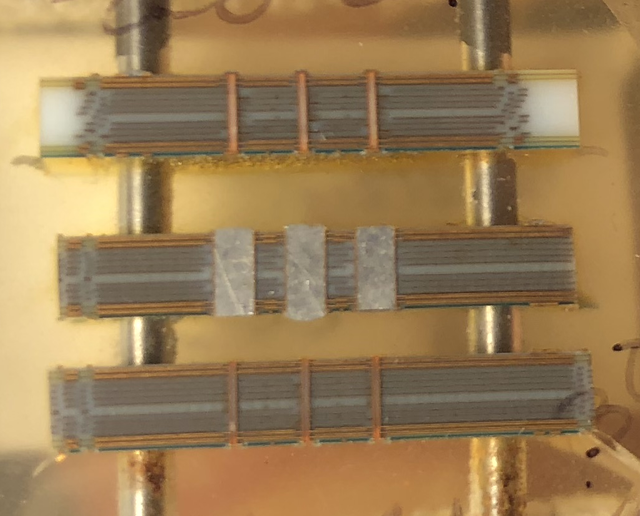

That only scratches the surface of the crazy things they make in these factories. I've seen circuit boards with over a dozen layers, all sandwiched together in a board no fatter than a pencil. As a matter of fact, here's what a cross section of one of those looks like:

The zoom is pretty rough, which just goes to prove how tiny they make these things! You can see the different layers, as well as the holes or "elevators" or "subway stations" that connect them all to each other.

Once you get a little deeper into this field, you learn about all the incredible things they do with this stuff. Trust me, I know -- I have a copy of the bible of circuit board manufacturing:

Anyway, I hope you enjoyed my little intro into this field. If you have any questions, feel free to ask and I will do my best to answer them! So the next time you look at a circuit board, think of all the wires we're saving by shrinking down the pathways into tightly packed and narrow conduits of electricity, connecting all the components. Another fun learning exercise is to break out an old motherboard and see if you can trace some of the pathways yourself.

Oh, and that green stuff? That's just a special paint called "soldermask" that get's applied towards the very end of this whole process. Before I got hired at the factory, I used to think that circuit boards were built out of that green stuff! So there really are no stupid questions.

Keep on learning!

Sources

- Two years personal experience in PCB manufacturing

- Coombs, Clyde F. Printed circuits handbook. New York: McGraw-Hill, 2008. Print.

@DollarsAndSense is a father, veteran, participant in the rat race, freelance writer, and volunteer EMT. Want to read more of my "educational" posts? Well, there aren't many just yet. Should I do more?

In today's news: Paywalls Are Everywhere

Unless otherwise noted, all text and images in this post are my own and may not be reused without my permission.

Join us @steemitbloggers

Animation By @zord189

Have you played with the Raspberry Pi? It is an inexpensive computer with a few exposed terminals to which one can attach electronic devices. The device appears to have spawned a great deal of interest in circuit boards and basic computer electronics.

You know, I've heard a lot about it, including several posts right here on Steemit, but no I've never gotten into it. It seemed sort of like LEGO Mindstorms for grown-ups (which is very cool by me, no put-down intended by that statement).

I guess if I had more time to "tinker" I would consider picking a kit up, but sometimes I feel like I just don't have enough hours in the day as it is! (as evidenced by the fact that I meant to actually get back to you about 20 hours ago!).

I've noticed that the Raspberry Pi is really popular among high school and college students. It seems to be the new entry level drug for young hardware nerds.

I cut my teeth on the 8086, but I never could get external devices to interface with the computer as doing such used to involve creating drivers. So, i put the Raspberry Pi on the list of things I hope to buy with my STEEM fortune.

Good luck finding time to tinker.

We are SO proud to have you as a member of our

FANTABULOUS @steemitbloggers family!

uvoted and resteemed!

❤ MWAH!!! ❤

interested in joining the Steemit Bloggers Community?

Really interesting read!

Thanks! I was trying to strike a balance between simplicity, thoroughness, and making it easy/fun to read. Any suggestions for if I try something like this again? I could easily write two or three more of these about other parts of PCB manufacturing.

Personally, I like variety from the people I follow. You are a good writer, the stuff you write is well organized and illustrated and easy to read and follow. Then again, other people expect more consistent stuff from the authors they follow. I have no clue what people expect from me lol, and looking at my blog I am all over the place but then again it's not like steemit is people subscribing to "home and garden" when they follow you and then being horrified when they get an issue of "heavy metal."

I sense I am rambling, I do that...

I think you did a great job in your write-up and I enjoyed it, learning things I didn't know.

If you were to do part 2, I'd enjoy it as well.

If you were to write an article about sheep farming in New Zealand I'd probably enjoy that too =)

Hah, you and I have similar tastes then - probably part of the reason for the mutual follow 😅

Wow, completely interesting for me! I'm happy to resteem this as part of the steemitbloggers relay!

It’s pretty crazy to me how much was done with chemicals versus mechanical processes! Thank you, much appreciated!

I already knew some basics of it, but you have a good explanation!

No screwdrivers and soldering irons small enough to get into a circuit board with this amount of miniaturisation! It starts to get crazy with the manufacturing of CPUs...

Ugh, I can’t even imagine! Our boards were actually large enough that you could get away with picking out copper shorts with an X-acto knife to save a board from being scrapped. But yeah, you can get TINY. I looked at the board in my phone once and was just floored at how tiny the circuits are.

Upvoted and resteemed!

Proud member of #steemitbloggers @steemitbloggers

Thank you, sir! Much appreciated 🙂

I see circuit boards from old battery operated toys. Now I have an idea how it works. Your beginners guide is awesome. Great way with the explanation connecting to breaking bad by the way. Loved the show.

Thanks! Yeah I remember being amazed at how this acid could eat through solid metal but leave this flimsy plastic alone. Cool stuff, and that show was smart for talking about it.

This was a very cool explanation! Perhaps more than I wanted to know. LOL

Thanks for educating us and have a good weekend!

🙌