ELECTRICAL PANEL 3: UNDERSTANDING SYNCHRONISIN PANEL (POWER SOLUTION)

Electrical Power is very important to our day to day activities. As the power supply is important so it is very not okay in some countries because of power outage experiencing in this area. As bi as some country is they has utilities power issue and that is why they cant do without some electrical panel if they will enjoy constant electricity supply. This piece will explain some detailed fact about another electrical panel called Synchronizing Panel. This is one of the panel designed/used to meet power system requirement. The panel function both manually and with an automatic synchronizing function for one or more generators or breakers.

Another word for synchronizing in electrical system is Parallel Connection. In parallel connection there are some factors that needed to be considered before this can be done.

Before any construction can be done the synchronization must matches the waveform of the output voltage of one generator with the voltage waveform of the other generator (s). That means the generator can be more than two connected in parallel.

Factors considered when synchronizing/paralleling generators

1.) Capacity: The construction is based on load demand. That is powering on a set when demand increases and switching off a set when demand decreases.

2.) Redundancy: ensuring a soft power transfer as the outgoing generator is switched off and the incoming one is powered on. The design should avoid a situation where the load is not powered or allowed to run on the UPS.

3.) Safety/Compliance: Compliance with the electrical standards in terms of safely, protection and operation.

When considering this panel construction we need to know that generators may have equal or different engine speeds, there must be speed control that will locked into the final speed of the system, which means there must be speed control consideration. In synchronization the resulting output must be in phase, with the same frequency and voltage hence compatible with load.

What are the components used in Construction of This Panel?

The under listed components are involved when considering construction of synchronizing panel.

1.) Cabinet IP 54

2.) Copper Bus-Bar

3.) Insulations

4.) Wires/Cables

5.) PVC Channels

6.) Transformers

7.) Protection circuits with fuse holder.

8.) Electronic automatic battery charger

9.) Meters and Switches

10.) ACBs, MCCBs or Contactors

Working Principle of this Panel

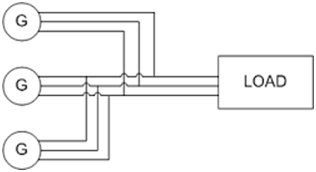

Panel Diagram Image Credit

Firstly, we need to understand that the panel will operate on an automatic mains failure system, so that immediately the main supply is being interrupted (after the delay period) the generator will start-up together. That means in synchronizing panel we have more than one generating set in operation. After the warming up period the en set will synchronize with each other by means of contactors or motorized circuit breakers onto a common bus bar. Read about Contactor here

Shortly after this above explained, the motorized change-over switch will trier/closed and the load will be connected to the main distribution box for operation.

The good about this panel is that during the running of the en set if there is a drop in the load one or two generators will be shut down automatically to save fuel consumption. On the other hand if the load increase again the second or third generator will be restarted, synchronized and reconnected to the load. Should the mains power supply returned, the motorized change-over switch triggered the whole system and send signal to the generator to shut down after the change-over to the mains supply has been done.

Importance of synchronizing panel

More control and savings on generating costs: The total amount of power supplied from several small generators is equal to the power supplied by one large unit. In considering small generator there is more control and balancing than in bigger generator.

Also in the areas of reliability considering this panel it will Improve reliability and redundancy for both critical and non-critical loads. What I understand is that the system ensures that there is always constant power to critical loads, and if one of the generators fails, the load is supplied by the other one or more parallel unit. The reliability of this panel is what make many organization go for this panel not even considering the cost implication it will cost them.

In conclusion modern power plants typically utilize automatic synchronizers and remember that an automatic synchronizers(motorized circuit breaker/contactor) send pulses to the generator exciter and governor to change the voltage and frequency of the unit. The synchronizer will automatically close the breaker when it is within an allowable window.

Thanks for taking time to read this short piece on synchronized panel.

Thanks for Following Me, I Remain My Humble Self Engr. Samest

Thanks to @stellabelle for gifs

It is good to know about what controls and keeps electric power in checks. Thanks for sharing your knowledge of the electric panel

thanks for commenting

uwc

Have been expecting this kind of post from you....

(My first question is that can this work with single change over switch?)

The second question is that, (can this work with single phase generator size 1.8 to be precise?)

if you are looking for single phase with this panel is not advisable. if you are considering a single phase changeover it means that the load can be too much which cant lead us to construction of synchronized panel. Synchronize panel is basically for an industry with heavy equipment of three phases not single phase.

Thanks for your reply @samest... This is what I just need to know:

It means the panel is useful for industrial electrical installations alone?

Thanks for giving the information on how to power our business. THis will really help a lot of people.

Thanks for commenting

What made you go into this field? I'm always impressed by people who can Master such technical subjects. It's a very informative post.