Automated vs Manual Electrical Safety Analyzers - Choosing the Right Tool for the Job

In the high-stakes world of healthcare technology, patient safety is non-negotiable. At the heart of any robust medical equipment management program lies a critical, non-negotiable task: electrical safety testing. It’s the first line of defense against potential hazards like electrical shock, ensuring that every device connected to a patient is as safe as it is effective.

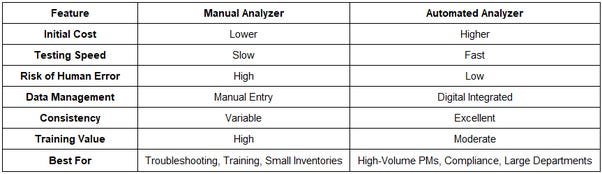

But when it’s time to perform these essential tests, a fundamental question arises: should you use a manual or an automated electrical safety analyzer? The choice isn’t just about price; it’s about efficiency, accuracy, and the specific needs of your department.

Let’s break down the key differences to help you make an informed decision.

Manual Electrical Safety Analyzers: The Hands-On Approach

A manual analyzer is like a sophisticated multimeter dedicated to safety tests. It provides the raw measurements, but the technician is in full control of the entire process.

The Workflow: You manually set the test parameters (e.g., 3000V for a dielectric withstand test), connect the leads, initiate the test, observe the result, and then meticulously record it — often by hand on a paper form or later typing it into a database.

Key Advantages:

Lower Initial Cost: Manual testers are generally less expensive to purchase upfront, making them attractive for smaller departments or tight budgets.

Educational Value: For training new biomeds, manual testers are invaluable. They force a deep understanding of why each test is performed and what the measurements truly mean.

Flexibility for Troubleshooting: When a device fails, a manual tester allows you to probe specific points in the circuit, change parameters on the fly, and truly dig into the root cause of the problem.

Key Drawbacks:

High Risk of Human Error: This is the biggest drawback. It’s easy to misread a value, select the wrong test, transcribe a result incorrectly, or simply forget a step in the sequence.

Time-Consuming: The entire process is slow. Setting up, performing, and documenting tests for a single device can take several minutes, which adds up quickly in a large inventory.

Inconsistent Results: Different technicians might perform or document tests slightly differently, leading to inconsistencies in the data over time.

Tedious Documentation: The manual data entry required is a significant administrative burden and a potential point of failure for your record-keeping.

Automated Electrical Safety Analyzers: The Streamlined Powerhouse

An automated analyzer is a step toward a fully integrated management system. You select the device you’re testing from a pre-loaded library, and the analyzer runs a pre-programmed sequence of tests, often storing the results internally.

The Workflow: Connect the device to the analyzer, select the test profile (e.g., “Ventilator — Annual PM”), and press “Start.” The analyzer executes the entire test sequence automatically, saves a pass/fail result, and can often export the data directly to your computerized maintenance management system (CMMS).

Key Advantages:

Speed and Efficiency: Automated testers are dramatically faster. They can complete a full suite of tests in a fraction of the time it takes to do them manually, allowing you to process more equipment in less time.

Unmatched Consistency and Accuracy: By following a precise, pre-defined script every single time, automated analyzers eliminate technician variability and drastically reduce the risk of human error.

Seamless Data Management: This is a game-changer. Results are stored digitally and can be uploaded directly to your CMMS, creating perfect, auditable records with minimal effort. This is crucial for compliance with standards like the Joint Commission and AAMI.

Enhanced Technician Confidence: The system guides the user, reducing uncertainty and ensuring that the test protocol is followed exactly as written.

Key Drawbacks:

Higher Initial Investment: The advanced technology and software integration come with a higher price tag.

“Black Box” Effect: Technicians may become proficient at running the tests without fully understanding the underlying principles, which can be a handicap when troubleshooting complex failures.

Less Flexibility for Unique Devices: While libraries are extensive, configuring a custom test sequence for a highly specialized or old piece of equipment might require more setup time.

Head-to-Head Comparison

The Verdict: It’s Not Always an Either/Or Choice

So, which one is right for you? The answer often depends on the size and needs of your healthcare technology management (HTM) department.

Choose a Manual Analyzer if: You have a small inventory, a limited budget, or you need a dedicated tool for in-depth troubleshooting and technician training.

Choose an Automated Analyzer if: You manage a large fleet of medical devices, prioritize efficiency and throughput, and need robust, auditable data for compliance reporting.

However, the most forward-thinking departments often find value in having both. An automated analyzer becomes the workhorse for routine preventive maintenance on standard devices, ensuring productivity and perfect records. A manual analyzer remains in the toolkit as a specialized instrument for troubleshooting failures, testing non-standard equipment, and educating new staff.

The Bottom Line

Investing in the right electrical safety testing technology is an investment in patient safety and operational excellence. By understanding the strengths and weaknesses of both manual and automated options, you can equip your team with the right tools to build a safer, more efficient, and fully compliant medical equipment program.