TRASH REJECTED!! $185 Vacuum Forming Machine Left For Dead Repaired & Sold To An Orthodontics School

This was a fun project that will now help orthodontic students at the school I sold it to treat patients for years to come.

In other words, the things out there for recycling/upcycling/freecycling don't just help the environment and provide income. They can also help others downstream to keep the goodwill flowing forward.

What did you find? Glad you asked.

I found this dental mold forming appliance sitting on top of some bags on the curb. I had no clue what it was at first sight, but it looked like good money.

Proof:

It works by the top heating a dental mold plastic sheet to the point where it can be pliable. The heat source is twisted to the side and the sheet holder is lowered to the base where a vacuum creates powerful suction through a base layer of metal balls. This forces the sheet to contour perfectly over a patient's dental mold resting there. The process is very fast.

Yes, we've all been overcharged for the making of our retainers in the past, but I digress.

Anyway, it was in great cosmetic shape and begging to be saved.

My thought process:

- It could still be functional and they upgraded to a newer model.

- The vacuum motor gave out.

- Blown fuse or internal wiring issue.

Should this have been trash? Perhaps if it was broken and the previous owner wasn't handy or cared enough to get it repaired. If it was working, it should've been donated to a mission in another country to help with the underprivileged. Either way...

Not in my house!!

So what happened?

- The unit didn't power on, so I had some thinking to do

- Step 1: find the fuses

- Step 2: rejoice as one of the two fuses had blown

- Step 3: replace both fuses for insurance... WE HAVE POWER

- The unit had two functions (heat and vacuum)

- The fuses solved the heat, but the vacuum wouldn't work

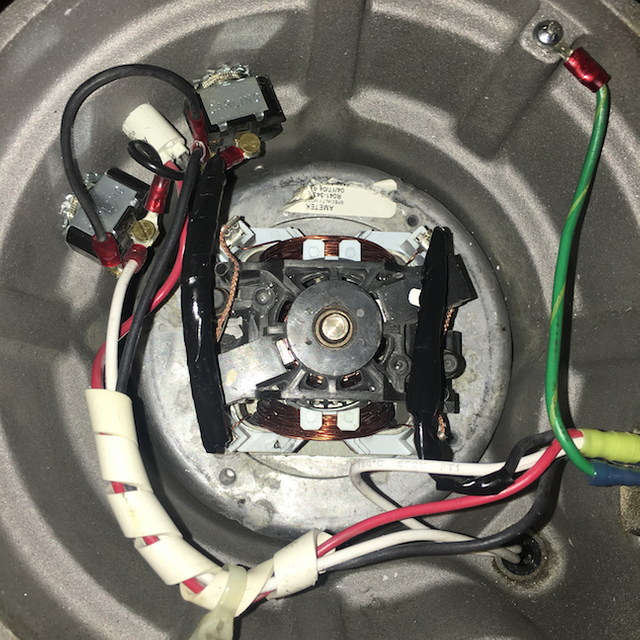

- Step 4: take the bottom off and check the wires. BINGO...

- The two vacuum wires got wrapped around each other and worn through by the spindle in the middle of the motor.

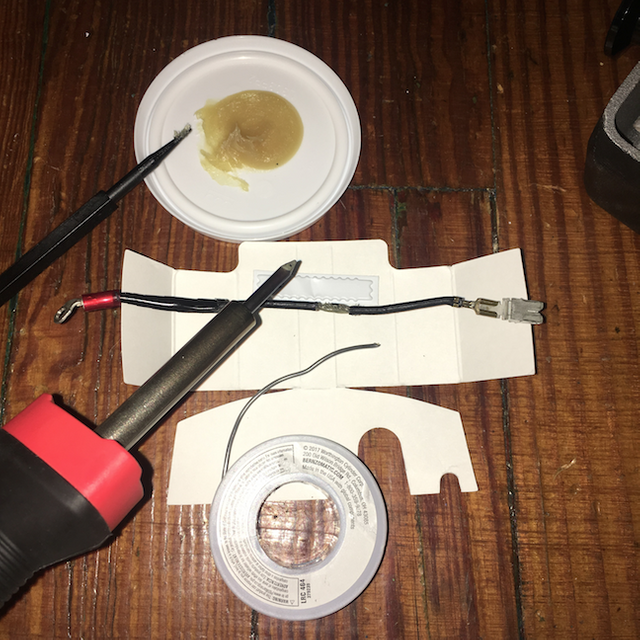

- Step 5: soldering time!!

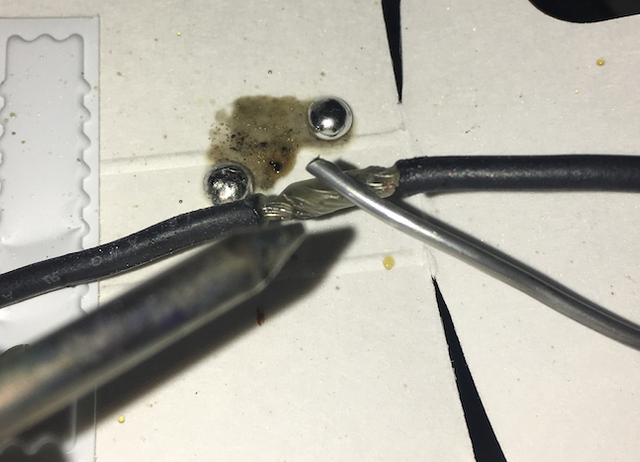

Wire 1's turn with a soldering iron, flux and solder...

Some electrical tape and heat shrink wrap for good measure...

Wire 2 couldn't be removed from the unit, so I had to solder it a little differently. Step-by-step process shown to educate others:

All better now!!

Since the wires originally tangled from a loose motor that was able to rattle around inside, I put some electrical tape on the metal prongs that were supposed to support it in order to prevent any future twisting. Since I reinforced the wires with tubing and tape, and molded them to be firmly on the sides of motor, this shouldn't happen again.

Tip - it's best to heat the flux and solder from under the wire so it drips through via gravity.

Hopefully this was helpful to see how you can find and troubleshoot issues that others simply didn't want any part of. This was an easy fix and good wire work practice.

The unit sold for roughly $185, so it was worth the time. The direct costs of doing this fix were about $5.

El fin,

seems like you can be a legit handy man!

nice!!!!

Excellent work, you got the skills that I do not!

Yes you do... Unless you trip the circuit breaker every time you try to repair stuff.

Well, that's an interesting find! It's amazing the things you find and the people who throw this stuff out. And great that you can get it fixed and put into fresh hands!

Wow...I can see how handy you would be to have around :D Part of the magic is realizing what you are actually looking at, I imagine? I think every person of school age should have to take basic shop classes. Great job!!

Thanks. My Dad never taught me how to do any of this type of stuff. For no good reason, he didn't really trust me much around his tools and "work side" of the basement. Learning these things on my own is more fun than anything since it helps me understand how things work on the inside.