Yet another ATX Benchtop Power Supply

Yet Another ATX Benchtop power supply

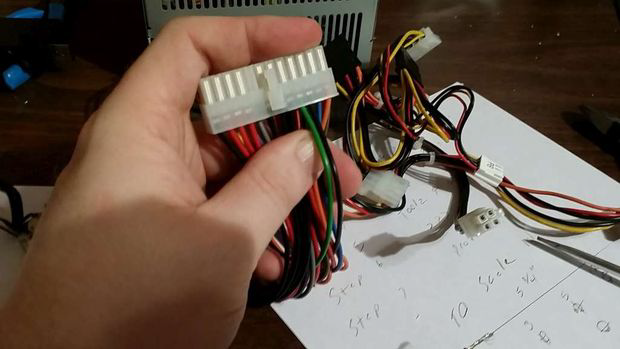

Today I am going to give you a quick rundown of how I turned the Above ATX computer power supply, into a decent benchtop supply. The desire is to charge batteries other gadgets and provide a base to power other gadgets made of salvaged stuff. Oh yeah and the standard disclaimer WARNING ELECTRICITY, SHARP OBJECTS, DO THIS AT YOUR OWN RISK: If you drill into your leg (, table, hand, arm, etc...) or shock/electrocute yourself, burn down your house (shop, dog, garage, etc...) I cannot be liable as there is inherent risk in life.

List of Materials:

1x ATX power supply (pulled from scrap pile at work)

3x Red 5 way binding posts (scrapped from junk speakers )

3x black 5way binding posts (junk speakers)

1x 12v single throw automotive switch (stripped from wrecked fire truck)

1x 12v red LED marker light (stripped form wrecked fire truck) piece of scrap light ply

Misc. crimp ring terminals, wood glue, wire nuts, double stick and electrical tape.

Tools:

Drill with bits (or something to drill a hole)

Exacto Saw (or something to cut the ply)

Ruler

Pencil

Paper

Terminal crimper

Wire Stripper

Wire Cutters

Step 1: What wire is what.

I decided to leave the bundles of wires for hooking up drives and peripherals as they are pretty standard and I would be able to plug a standard PC component into them with out any hassle.

I could rehash everything anyone has ever said about an ATX power supply but instead, I am going to just link the Wikipedia article on them. There is a lovely color-coded chart of what does what

https://en.wikipedia.org/wiki/Power_supply_unit_(computer)

After reading that article you will know that there needs to be some sort of dummy load on the power supply and the green wire needs to be grounded to turn it on. I decided that the Green wire will be attached to a single throw switch and that my dummy load would be a LED light so that my fool head knows that the power supply is

on. I could listen for a fan but that would indicate I am not listening to the radio whilst I tinker.

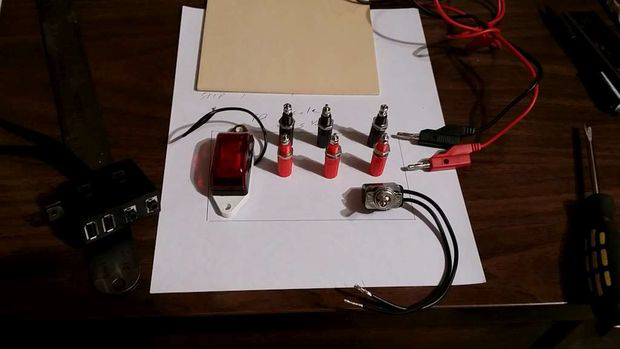

As I don't have a fancy laser cutter or access to one I do things the old-fashioned way. I use a saw an drill and as many existing edges as I can. My piece of light ply was about 6 inches wide so that is my width. the height is determined by the length of the LED marker light and everything seemed to fit in the resulting 6x3 inch panel. I took my ruler measured 3 inches back from the edge in several places and made my line to cut the panel face.

Now that you have a basic rundown of what wire is what it is time to start the planning and sketching phase of this party. I thought I had a picture of my sketch but I apparently didn't. After mocking up where I wanted to put things on the panel I had to start making it. I measured where I had things on my 1:1 panel sketch and

started marking them out on the board.

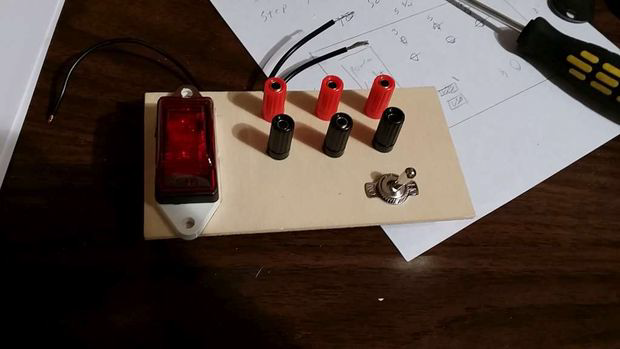

I then measured the diameter of my 5 way binding posts and drilled the appropriate holes, with a slightly larger hole for the switch. After drilling the appropriate holes secure the switch and the binding posts to the board with their appropriate lock nuts and washers.

Step 2:

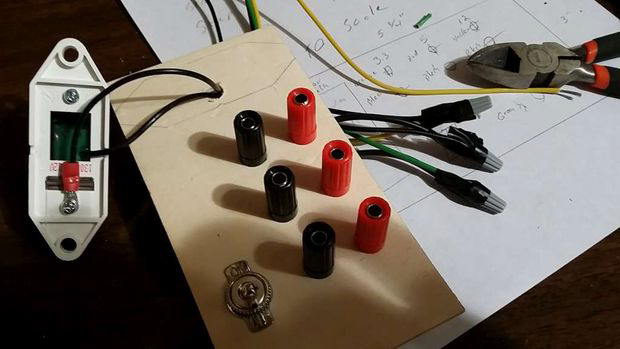

With the 24 wire bundle shown in the last step and the chart gained from Wikipedia, we know that Green is the signal wire and black is ground. I stripped 1/4 inch of the insulation from the green wire and ground to twist to the leads coming from the switch. You can either solder the leads or use wire nuts. I went with wire nuts as I may

want to take this all apart some day and reuse the switch and LED.

After twisting on the wire nut I like to secure them further with a wrap or two of electrical tape.

The LED is a little complicated as it is designed to mount to a vehicle where the whole truck is the negative grounding plane. So there is only 1 wire coming from the LED, As it came from a truck I twisted the positive wire to a yellow (12V) wire from the PSU ( as I am only clipping wires as needed I can leave the unused leads alone in the 24

wire plug.)

I clipped another Black Ground wire from the bundle and crimped on a ring wire terminal end. There is a screw on the underside of my LED lamp assembly that connects to a plate that would connect to a mounting screw. I backed this screw out. I liked it so I put my ring on it and screwed it back in.

At this point, you can test the PSU to ensure that it turns on with the power switch. Plug your grounded cable into the PSU then into the wall, Flip the switch and the LED should illuminate and the PSU fan should spin. If not check the connections you have made so far. (My first time the ground was not aligned properly on the LED)

Did it light up? Great now it is time to start wiring up the binding posts. Turn off the switch, and unplug and remove the power cable from the PSU. Get some double stick tape or wood screws and fasten your LED to the panel.

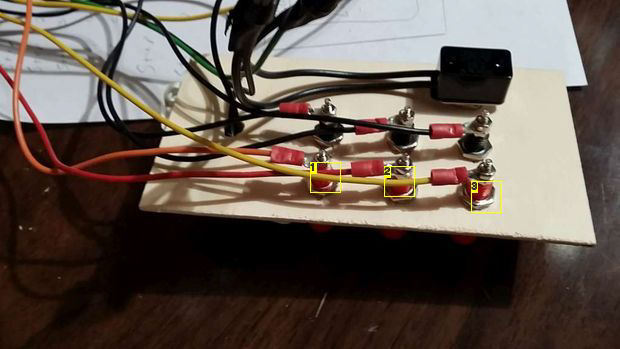

Find an orange wire (+3.3V) a red(+5V) and a yellow (+12V) and 3 Black (ground) wires. Strip 1/4 inch of insulation off the end of each wire and crimp on a ring terminal.

There is a small nut on each binding post I placed my ring terminals between the 2 nuts and then tightened them together with the needle pliers jaws on my wire cutter.

I wired my panel so that the voltage ascended in value from left to right. with 12V on the right, however, you can use whatever layout you choose. The panel is now wired up and now it is time to test it all out clean up the bundle and label the terminals.

I used small zip ties to keep the wires from the panel to the PSU neat. And made small triangular end plates for the panel out of more scrap light ply. It keeps it looking neat and tidy and small parts from rolling behind it. The LED received a piece of electrical tape on the face to dim it down a bit as it is freaking bright and you can see from my multimeter (set on DC) readings what poles are which to label.