Indulging in Cryptocurrencies (part 2)

I printed out the 5 cryptocurrencies in 3D yesterday evening 8 PM Dutch time, using the Prusa 3d printer and the Slic3r software. The quality of the cryptocurrencies turned out very good but it took very long, much longer than using my old 3d printer, the Printrbot Simple metal in combination with the Cura software. With Cura you can see how long it will take and much filament the model needs and the total weight of the model. These things are not visible with Slic3r. I also noticed that when I print something with the Printerbot Simple Metal 3D printer, it is much faster, but the quality isn't that great. With the Prusa I believe it takes 2 times printing! So when a model takes 4 hours printing with the Printrbot Simple Metal, it takes 8 hours with the Prusa or even more.

So I start printing these logos at 8 PM Dutch time and when I wanted to go to bed, it wasn't finished yet. I am not sure when it was finished. Maybe 2 AM?

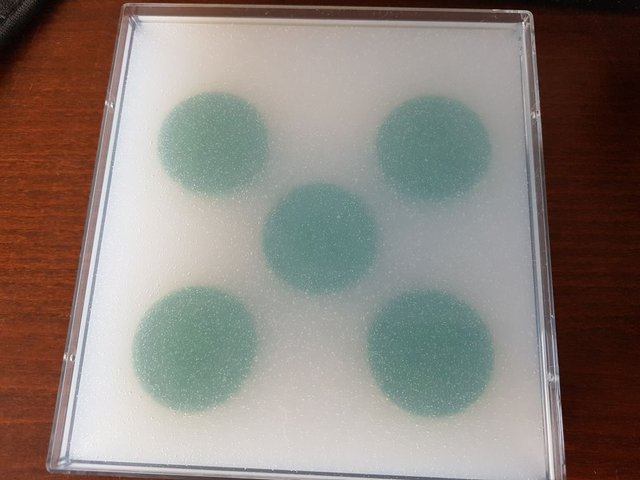

When I woke up I was very curious how they look like. They look very smooth although the Bitcoin logo shows 2 small tiny holes.

At 11 AM (Dutch time) today, I started printing the box for the cryptocurrencies.

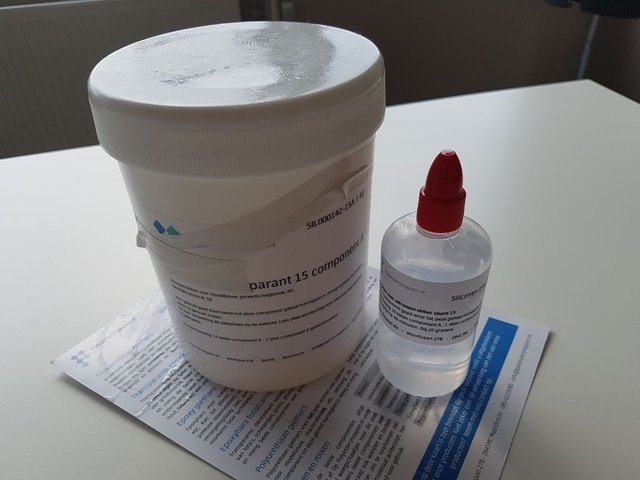

Time to make the silicone mold!

We need liquid silicone rubber Shore 15. They exist of component A and B.

A container.

Dubble sided tape to tape the models

Hand gloves. These are way too big for me and I couldn't find size Small.

A measuring cup with a wooden stick to stir.

A kitchen scale.

And of course the printed cryptocurrency logos in 3D.

So I taped the logos at the bottom with double sided tape and I attached them on the bottom of the container. Then I weighted the two components and mixed them for 3 minutes. I slowly stirred it and poured the silicone into the container. There are many air bubbles and I was just hoping the bubbles would go away. The room temperature shouldn't be higher than 20 degrees in order for the air bubbles to escape. I couldn't open the door or window because it was a stormy day. Today's weather was almost a hurricane!

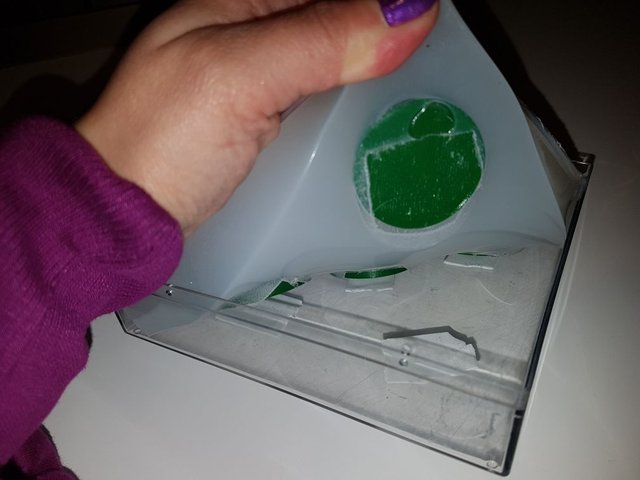

8 hours passed and I could already remove the silicone cold from the container. I was a bit scared because I didn't want to damage the container. It's a container from my previous Samsung phone. I was thinking how I should remove it.

At the end I took a metal ruler and just removed a bit with the ruler and then just pull it with my fingers. The logos came out very easy, especially the Steem logo ;-D.

Look at the Steemit logo! I still have to cut a bit at the opening.

Wow! You even can see the Samsung logo!

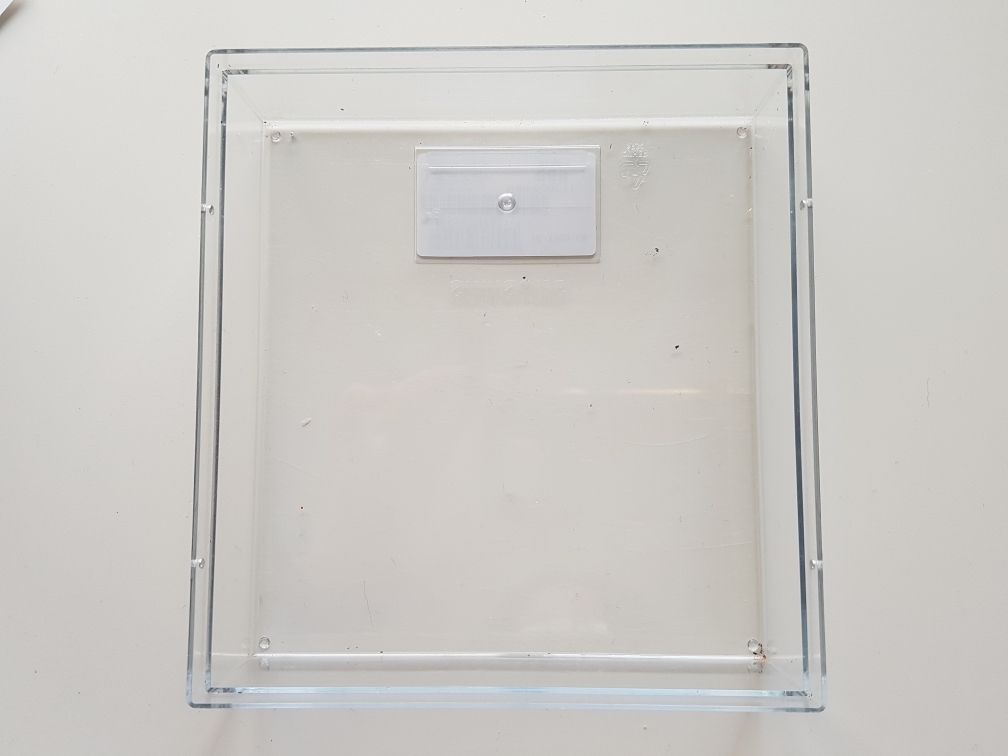

What do I hear? The 3d printer stopped printing meaning the box is ready. So I started printing this box at 11 am and it just finished at 9.45 pm. That's almost half day printing! It looks beautiful but it has some warping issues :-(. They are not visible on the picture. It doesn't look nice so I didn't make a picture of the sides. Maybe I will in my next post. I still need to print out the cover of the box....

Sangat menarik kak, sukses terus kakak

Terima kasih @fikri. :-).

Sama-sama kakak @fathin-shihab

Apakah punya discord? Ada yang saya ingin ajak diskusi.

bisa di steem chat.

I'm betting that your Cura and Slic3r configurations for your printer are very different, particularly in print speed. There definitely shouldn't be a factor of two difference between them unless the head movement speed is greatly different – and mechanically they shouldn't be.

I'm betting that the Printerbot is printing with a head speed of more than 60 mm/s if you are seeing appreciably better quality at twice the time on the Prusa. If I remember correctly, Prusa configurations default to something between 20 to 40 mm/s.

Also, there's no reason you shouldn't be able to use Cura with the Prusa; both printers just interpret gcode that's sent to them from processing the STL. I've found that the ideal solution for my purposes is to drop a few bucks on a Raspberry Pi and use OctoPrint as the print manager for the 3D printer. That lets me put gcode on the printer server from any of my machines and using any slicer, which is vastly more flexible. It also means that you can monitor printing from anything with a web interface, including a tablet or your phone.

I think you're going to find that is going to be the way forward if you can.

I asked my husband (@tarekadam) if Cura can be used for Prusa, he said unfortunately no because of the settings I believe. Maybe one day he can check again because I prefer Cura over Slic3r. That would be cool to check from your tablet or phone :-)

amazing ,, you are very creative. i like @ fathin-shihab.

Thank you @yanakellen :-)

Awesome idea! Very fun and creative. You put so much time and care into your projects, and it really shows.

Hubby keeps hinting that he wants a 3D printer, but we are going to have to wait until we can move and have more space... we already have no room! haha I could totally see myself making good use of it though, especially with such fun inspiration.

Thanks @offbeatbroad. Yes, i always try to make good content posts :-). Many men like to have a 3d printer nowadays. In the beginning i thought it was wasted money and i told my husband not to waste his money on a 3d printer. : -D. Now im taking over hahaha! You should indeed get one. :-)

wow that is very addictive to see wonderful this is so nice :)

Outstanding post and amazing photo , so creative Thank you for sharing!

resteemed

Congratulations! This post has been upvoted by SteemMakers. We are a community based project that aims to support makers and DIYers on the blockchain in every way possible. Find out more about us on our website: www.steemmakers.com.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.

Thanks @steemmakers! I can not wait till you are ready to be used! :-). Good luck!

Its pretty creative cryptocurrency products. Various looks cryptos you've produced. Awesome creativity.

Go ahead with steemit.

Wow it turned out pretty neat! I'm playing with my 3D printer as well, might try something similar :)

Thanks! I would like to see some of your designs printed :-)