The Market for Counterfeit Electronic Parts

A makeshift components "recycling" operation in southern China.

Summary

Despite the industry's best efforts to eliminate it, the scourge of counterfeit manufacturing plagues the electronic component industry. Design or component engineers and buyers require an edge to help eliminate the risk of encountering fakes in the supply chain.

Counterfeiting has a long and ignoble history. In the early days of electronic components manufacturing, counterfeiting has been looked upon as an ever-present plague. However, as the variety and sophistication of electronic components grows, so does the level of effort that counterfeiters employ to fabricate and ply their wares. Buyers of electronic parts face ever-escalating risks at the hands of counterfeiters, and should be aware of what they can do to reduce risk while remaining competitive in the market.

Introduction

Many vendors in the electronic components supply chain advise only to purchase from franchise distributors or manufacturers directly. However, in the real world this is usually neither possible nor practical. In the absence of factory-direct and franchise purchasing, some buyers must turn to the gray market. While the "gray" moniker may invoke images of an unexplored territory to be tread upon with caution, there are indeed many independent brokers that provide legitimate, reliable options as answers to buyers' needs.

Since the earliest days of electronic component manufacturing, counterfeiting has been an ever-present — albeit unpleasant — reality accompanying the gray market. Counterfeiting was virtually unheard of 15 years ago. However, several factors have made counterfeiting a lucrative endeavor for those willing to take up the dark mantle:

- With a ubiquitous acceptance of technology into both commercial and consumer goods, the overall demand for electronic components rises. This provides manufacturers with the ability to operate at a relatively healthy profit.

- This opportunity sets the stage for counterfeit manufacturers to make profits that match — or even exceed — those made by legitimate manufacturers by creating parts that can replace the originals at a fraction of the true manufacturing cost.

- The advent of microscale component manufacturing imposes no barriers to counterfeit organizations willing to invest in faking parts at the same level of detail. Fake parts show up more frequently as sophisticated technologies with an uncannily close match to their genuine counterparts.

- The "cost" of sophisticated components (such as FPGAs) continues to rise and the functionality is so complex that the parts are difficult to test in other than a production environment.

- The laws of supply and demand will never be perfect. Manufacturers continue to experience difficulty in accurately forecasting their component bill of material (BOM).

When it comes to the detection of counterfeits, gone now are the days when simple inspection sufficed. Mere checking for discrepancies between the parts packing list (or spec sheets) and the information shown on packaging and labeling of the box no longer safeguard buyers from illicit parts. Buyers of electronic parts should be aware of what they can do to reduce risk while remaining competitive in the market.

What is a Counterfeit?

There are many interpretations on what "counterfeit" actually means. Below are some of the more common examples. While there may be some overlap to these definitions, this only serves as a testament to the nefarious nature of counterfeiting.

Blanks — Empty bodies of components with no wiring or internal circuitry. These counterfeits have no functionality but look genuine superficially.

Non-functional parts made to look like genuine components. Historically, fake parts of this category show up more often as parts of less sophisticated technology. For example, a simple capacitor is more easily replicated than a chip designed and produced in microscale detail.

Fully functional illicit parts made to look like real parts. While the instance of these parts coming from unauthorized production facilities is relatively rare, these parts can easily be "third-shift" products — products made at an actual manufacturer-approved facility. For example, an approved manufacturer facility may turn out fully functional, fully authorized components during the first and second day shifts of the factory's regular schedule. However, after the factory officially closes, workers may return some hours later for an unofficial "third shift" to continue producing parts which are later sold off the company bill. These parts are made en masse, and are usually not subject to the same production standards that legitimate day-shift parts see — even though they may be fit, form and function replacement. They may be of inferior quality. Worse yet, some do not function at all.

Mislabeled parts that have inferior or unmatched function. These components are introduced into the supply chain by several methods. Most commonly they are components produced against high specifications, but fail one or more standards and are earmarked for disposal — not destruction. After their unauthorized recovery from disposal, these parts may be relabeled to match the specifications of parts whose quality standards they do meet. Other repurposing of these components may include labeling for parts of similar appearance and an entirely dissimilar function.

Partially functional components made to look like the genuine item. Parts such as these may be a variant of the mislabeled parts mentioned above, but which may pass as the actual parts for which they are labeled. These parts are more difficult to detect because frequently they don't show any sign of external manipulation in labeling. They frequently bear their original labeling.

Mislabeled parts that have an entirely different function.

Older parts relabeled as new parts.

Refurbished and recycled parts reconditioned to look new and relabeled as a different product.

What Counterfeit Is Not

It is legal in some countries to recycle fully functional parts from IC boards and sell them as they are — without relabeling. However, depending on how sensitive the parts are and how they are handled during the process, the parts may appear damaged but work well. With rougher handling they provide only partial or substandard functionality or, may not work at all.

Why is There a Counterfeit Market?

Inefficiencies or weaknesses in the supply chain abound. With such abundance come just as many opportunities — opportunities that counterfeiters seek out.

Obsolescent / Hard-to-Find Stock — All components undergo the same stages of market maturity. The electronic components industry defines' these stages, but they all conclude with obsolescence. For those components which some buyers need to keep in continuous supply for long-term products — such as military and aircraft systems — there is little recourse but to turn to the gray market. When this happens, opportunity arises for counterfeiting. The customer need is high and so the normal "risk threshold" increases with the need. Re-designs are out of the question due to support costs.

"Fab Shortages" — Manufacturers ("fabricators") use all manner of forecasting to determine how much product they turn out and when they produce it. Whether their forecasting is accurate is sometimes out of their hands. Manufacturers may inadvertently create "fab shortages" when their production based on estimated demand falls short of real-world demand. Perhaps their product exceeds forecasted demand, and then the manufacturer becomes hard-pressed to match a sudden rise in demand. Any unfulfilled market demand and accompanying lead times create the opportunity for counterfeit suppliers to fill in the gap.

"Lean Mentality" — Within recent decades, EC supply chains have adopted and supported Lean Manufacturing and just-in-time (JIT) fulfilment. While these methods have helped to promote efficiency in the supply chain, they also contribute significantly to opportunities for counterfeit supply. By not keeping ample stock on-hand, suppliers without genuine stock on-hand now force buyers to turn to the gray market. This increases the chances of coming across counterfeit products.

Lack of Alternative or Upgrade Parts — Some counterfeiters see opportunity in supplying illicit parts that mimic specialized or one-of-a-kind components that are either discontinued or have few to no alternatives available. Ideal alternatives to parts like these would either be produced by OEMs or CMs tasked with short-runs. Yet another, perhaps better, alternative to an original part would be an upgrade component that provides similar or superior performance when compared to the original. However, because these alternates are in scarce supply — or were never produced at all — shortages on the original component amplify the desperate component buyer's need. This provides an ideal opportunity for counterfeit production.

Extreme Supply Chain Interruptions — Sudden catastrophes — best exemplified by the recent Japan earthquake — may knock out a manufacturers' production capability. If no alternate manufacturer is available, this provides an opportunity for counterfeiters to "fill in the slack" with illicit components.

Long-term Component Demand / Life Cycle — For electronic assemblies that will be used for the long-term, these assemblies may remain in use well after OEMs and regular CMs manufacture them. Authorized and unauthorized manufacturers may be willing to keep up with continuing demand. This long-term market opportunity allows counterfeiters time to acquire and reverse engineer genuine components, and thus ramp up on their technology for creating convincing fakes. Military and high-investment / slow ROI industries (such as aircraft / aviation) are especially susceptible to long-term component counterfeit markets.

Allocations — Allocations are also cause for shortages of components otherwise available for general consumption. Allocations may occur at any time in a part's availability life cycle. One such example of allocation arises from RoHS component lots earmarked for government applications.

Long Lead Times — While long lead times may occur at any time of a product's maturity, they usually take place in the early stages of a new product's introduction. In the early phases of its introduction to market, component production is limited or sporadic. Assuming the product is widely accepted and generates sudden demand, lead times may lengthen as the manufacturer struggles to ramp up production to meet rising demand. The gap between orders and fulfilment may create an opportunity for counterfeiters to provide product to fill that gap.

"Back Door" Sales — "Back door" selling of excess manufacturer stock to independent distributors. This may possibly allow indiscriminate access of real parts to counterfeiters who in turn reverse engineer the product and turn out inferior or non-functional knock-offs.

Electronic Waste — As time goes on, more and more electronic waste accumulates and provides the fodder from which the refurbishing trade arises.

"Third Shift" Parts — "Third shift" production of parts. (See the previous sections discussion of "third shift" products.)

Lack of Accountability — Lack of accountability on the counterfeiters' part is a condition of the counterfeit industry. Because they are not subject to numerous development hurdles that legitimate manufacturers face in the real world, counterfeiters are able to produce high-quality fakes on short notice. This makes the introduction of counterfeit parts into the supply chain relatively easy.

Buyers Exacerbate the Counterfeit Supply Market — Whether component products are either in plentiful or short supply, component buyers themselves can be a significant factor in illicit part manufacture. When a component reaches a supply shortage, buyers often move from mainstream distributors to the spot market. In doing this they sometimes put the word out that they require hard-to-find components. Some unwittingly put the signal out so fervently, that they "heat up" the market. In so doing, they often create a market for "hot" parts — or even phantom parts. Phantom inventories "miraculously" become available, and desperate buyers either purchase these bad parts, or place deposits down for parts that may not even exist.

If buyers work hard to put out the word that they are seeking hard-to-find components, they inadvertently "heat up" the counterfeit supply market, thus exacerbating the counterfeit market supply.

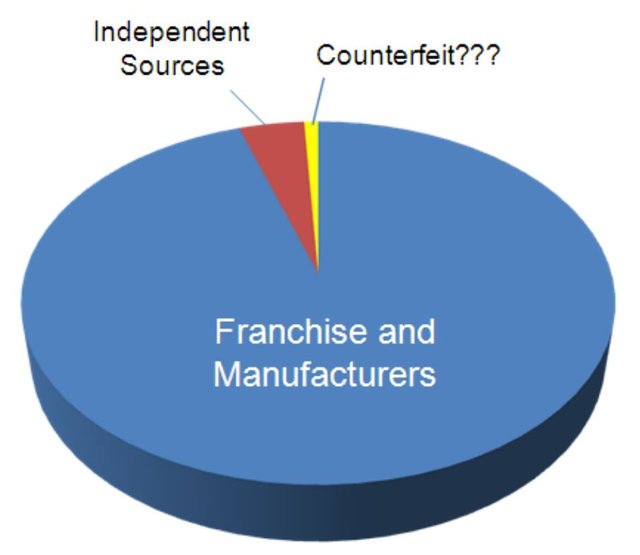

How Large is the Counterfeit Industry?

The overall component market is estimated to be $320 billion2. Industry experts estimate that on any given BOM, 1-5% of the parts may need to be purchased from the broker market. This means that anywhere from $3-16 billion worth of these products could be at higher risk as counterfeits. A 2010 US Commerce study of 98 authorized and unauthorized distributors of electronic components determined that 54 reported counterfeit products, and 44 of these were independent distributors — neither manufacturers nor franchisers'. During a three year period, 613 incidents of fake parts were reported. 576 of these incidents involved unauthorized distributors.

While the chance of encountering counterfeit components is small when compared to the overall market, the risks and costs associated with failing to detect them can be devastating.

- Based on analysis of information provided by New Venture Research Corp, 2010.

- As reported through Carbone, 2011.

What is the Cost of Counterfeit Parts?

Cost to the buyer depends where in the chain counterfeit components are caught.

Lowest cost at the supplier level — If the buyer seeks parts in the broker market, it is important to work with trusted brokers that screen components. The only expense here is the cost of screening and testing for, and replacing counterfeit parts. At this part of the supply chain, it is easiest to catch occurrences here.

Moderate cost if caught at the manufacturing plant before entering production line. Detecting fake parts at this stage may affect the production line. Because components here might have already passed the bulk of quality inspections, it is slightly more difficult to catch all occurrences of counterfeiting here. Rework charges are the main cost when counterfeits are detected at this stage.

High cost if not caught prior to manufacturing, but instead during QA screening. If caught before entering the end-user supply chain, you still face substantial reworking and screening costs, and may impact the ability to support ongoing product demand. Moderately difficult to catch all occurrences here.

Extremely high cost if caught after products have entered the end-user supply chain. Very difficult to intercept counterfeits at this phase. Manufacturers may need to recall products from multiple locations for rework and screening costs. They may also need to pull back and screen more units to determine the extent of the issue.

Exorbitantly high cost if caught after delivery and installation to end-user. Depending on the counterfeit type (for example, if it causes a product failure), the manufacturer could face product liability suits/damage claims, in addition to substantial rework and screening costs.

Other Costs

Other costs exacerbate the operational costs already incurred resulting from the failure to detect counterfeit components. Among these more expensive additional costs are:

Contract losses — Some contracts stipulate dates by buyers may receive bonuses for on-time or before-schedule deliveries. Contract losses may arise from missed productivity goals and late delivery of component-dependent products due to late counterfeit detection.

Bad faith and loss of later business — Component buyers may suffer bad faith and loss of later business from their customers.

Legal costs incurred in litigation arising from on-the-field failures of end products, subsequent recalls, and expensive reworking. In the medical device industry, these costs are especially high-risk, as defective or substandard components may result in the misdiagnosis — and even death of — a patient who otherwise may have benefited from the accurate readings a properly operating medical device.

Criminal costs and penalties. Whether they knowingly or unknowingly use, buy, or sell counterfeit electronic components, both buyers and their suppliers (including brokers) run tremendous risks. Judgments can be extremely harsh, and cannot be taken lightly. Stiff fines, closure of business, and even imprisonment may be rendered against buyers and suppliers based on judgments entered against them both by government authorities and the customers to whom buyers deliver their products.

Best Practices to Avoid Counterfeit Products

While the majority of gaps in the supply chain are out of the buyer's control, fortunately there are many points of influence the buyer can leverage. These add up to a system of best practices the buyer can use to greatly reduce the chance of encountering counterfeit products.

Implement an Interim Plan — In the absence of a short list of existing trusted suppliers, implement an interim plan whereby you continue buying from trusted sources — existing suppliers such as manufacturers and franchise distributors.

Ramp Up — Establish a selection process for qualifying new brokers with which to start doing business. How long has the broker or distributor been in business? What is their QA process? Do they have certification credentials (such as ANSI/ISO) that indicate they use mature quality systems?

Establish in-house quality standards, policies and procedures that cover the known gaps in your processes and those of the broker. Share these standards with brokers so as to level-set expectations. As the "risk" increases, then "test" more.

Verify your broker's QA process. What processes does your broker have in qualifying and disqualifying their suppliers?

A vendor vendor tracking system supports ranking of suppliers based on transaction history including dealings in counterfeits transactions.

Request parts traceability, verification, and "try-before you buy". Use caution with traceability: As there is no globally accepted standard for traceability, what's to stop a counterfeiter from producing traceability paperwork and reports for the parts they sell? Start with the basics. By asking "Where exactly are the parts now?" some interesting answers may arise. If a broker is willing to arrange for it, ask for photographs of the parts in the broker's supplier warehouse. Pictures may prove that the vendor has the stock in-house, or at least has a relationship with the true owner of the stock. Always ask for pictures of labels, packaging and the parts themselves. Contact the manufacturer for lot code identification. As a further step, ask the broker to have random samples of parts shipped for in-house testing.

Know thy broker — Demand intimate knowledge of brokers, their operations and their suppliers. Keep a running history of each broker and evaluate them periodically for risk. When in doubt, just walk away.

Incorporate flexibility into designs that reduce risk — By producing designs that accommodate alternative parts, replacement parts, and upgrades, you are broadening the overall choice for the parts which you could use to complete your design. Greater choice helps to reduce the counterfeit risk associated with using only one hard-to-find part. By having alternatives available, you are able to choose from a broader range of parts and suppliers whom you can evaluate and rank with the least risk. Determining alternate suppliers and products requires access to listings available in Intelligent Product Selection Technology vendors.

References

Carbone, J. (2011, April 19). Counterfeit components problem worsens.

Retrieved May 2, 2011, from Digi-Key Corporation - PurchasingPro:

http://www.digikey.com/us/en/purchasingpro/articles/supply-

chain/counterfeit-components-problem-worsens.htmlNew Venture Research Corp. (2010, July, September). New Venture

Research Reports. Retrieved May 2, 2011, from New Venture Research:

http://www.newventureresearch.com/products-services/reports/

© 2016 John Melendez - All rights reserved worldwide.

A very well documented article, i found by first time electronic counterfeit buying a usb storage....it was a really wrong experience (at end i lost all the data)