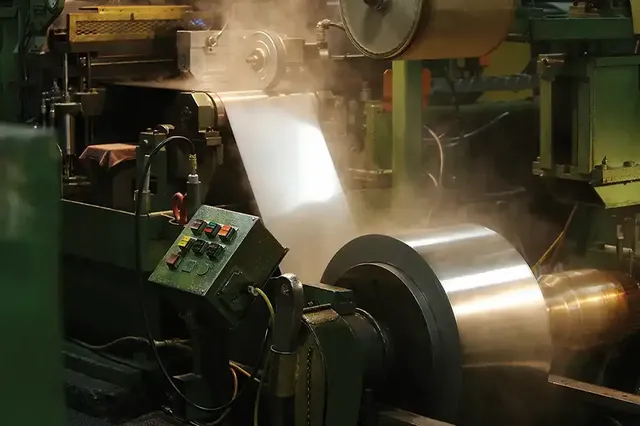

Continuous rolling mill

Rolling mills compress metal into a uniform thickness, bend it into custom shapes, and create custom-sized stripping. There are many different types of rolling mills, and the optimal mill for your product depends on the metal and rolling process your manufacturer will use.

Contact Details

https://api.whatsapp.com/send/?phone=008617538889778&text&type=phone_number&app_absent=0

Email:[email protected]

Wechat/Whatsapp:008617538889778

Tel:86-379-65188091

All sorts of markets require custom metal products to function. And because so many industries require custom-rolled metal, these products are extremely common in daily life. You’ve almost certainly used something produced by rolling mills at some point, even if you haven’t realized it! From your car to your cell phone to your jewelry, products created by rolling mills are used every day.

4-High Rolling Mill

Rolling Mill Uses

Just about all metalwork is custom in some regard. Because of this, there are many different types of mills—and different uses for each one. For example, one mill might specialize in flat rolling and another in working on grooved rolls. A large mill will have a higher rolling load capacity, but not all jobs are large enough to require so much raw material.

Custom metalwork requires fine-tuned machines that can create products like wires, strips, and banding out of a variety of metals. The rolling operation and equipment used will depend on what material is needed and what the end result will be.

Main Types of Rolling Mills

The different types of metal and the specifications of the final product will help determine which type of rolling mill your product will be produced with. Here are a few of the main types of rolling mills:

Continuous rolling mill. Sheet metal passes through several rolling stands, each pressing the metal thinner.

Cluster rolling mill. A cluster of metal rolls are lined up to be thinned out.

An example of a cluster rolling mill would be a 20-High Cluster Rolling Mill. These mills offer impressive accuracy tolerances by bearing the rolling force along the entire width of the rolling mill through the backing bearing. Some featured advanced technology, including automatic gauge control and dynamic power crown adjustment.

Planetary rolling mill. This type of roll mill is mainly used to crush or grind down raw metal rolls.

Two-, three-, and four-high rolling mills. Determined by the mill stand quantity, these mills roll in opposite directions to press and finish the metal.

In addition to the different types of rolling mills, your metal manufacturer might use a cold rolling mill or a hot rolling mill to work certain types of metals and create different products.

Continuous rolling mill rolling is an efficient metal processing method.

Working principle

The continuous rolling mill consists of multiple rollers, through which the metal billet passes in sequence. During the rolling process, each roller exerts a certain pressure on the metal, making the metal gradually thinner and longer, while changing its shape and properties. The speed and rolling force of each roller cooperate with each other to ensure that the metal maintains a stable speed and tension during the continuous rolling process.

Advantages

High production efficiency: Due to continuous rolling, the number of heating times and intermittent time of the billet are reduced, which greatly improves production efficiency.

Good product quality: The continuous rolling mill can accurately control the rolling parameters, so that the product has high dimensional accuracy and good surface quality.

Energy saving: Compared with traditional single-frame rolling, the energy consumption of the continuous rolling mill during the rolling process is relatively low.

Application field

Continuous rolling mills are widely used in steel, non-ferrous metals and other industries to produce various plates, strips, pipes and other products. For example, in steel production, continuous rolling mills can produce hot-rolled steel plates, cold-rolled steel plates, galvanized plates, etc.; in non-ferrous metal processing, they can be used to produce aluminum plates, copper plates, zinc plates, etc.

Ensure the normal operation of the equipment: Before rolling, the continuous rolling mill should be fully inspected and debugged to ensure that all components operate normally and the electrical system is stable and reliable.

Control rolling parameters: Strictly control rolling temperature, speed, tension and other parameters to ensure product quality and equipment safety.

Do a good job of maintenance: Regularly maintain the continuous rolling mill, replace worn parts in time, and keep the equipment in good condition.

How to protect steel pipe from corrosion?

What does salt do to aluminum?

Induction furnace and steelmaking