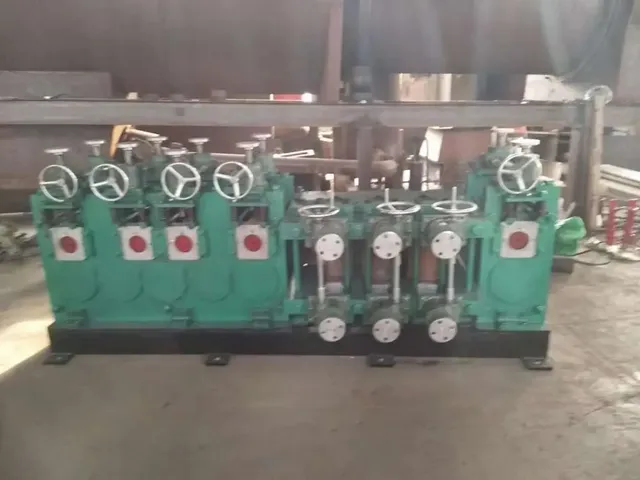

Combination rolling mill

Combination Rolling Mill for Sale: Revolutionize Your Metalworking Operations

In the world of metalworking, having the right equipment can make all the difference in achieving high-quality results, maximizing productivity, and staying competitive. Our combination rolling mill is a top-of-the-line solution that offers a plethora of features and benefits, making it an ideal choice for various metalworking applications. Whether you're a small workshop owner or a large industrial manufacturer, this machine is designed to meet your needs and take your metalworking operations to the next level wire rod production line.

Introduction to the Combination Rolling Mill

A combination rolling mill is a versatile and powerful piece of equipment that combines multiple functions in one unit. It is specifically designed to shape and transform metal sheets, bars, and wires into the desired forms with precision and efficiency. This type of rolling mill typically incorporates different types of rollers and mechanisms that allow for a wide range of rolling operations, such as flat rolling, shape rolling, and wire rolling.

Our combination rolling mill stands out for its advanced engineering and innovative design. It is built to withstand the rigors of continuous use in a demanding industrial environment while delivering consistent and accurate results. With its user-friendly interface and adjustable settings, operators of all skill levels can quickly learn to operate the machine effectively, ensuring a smooth and seamless production process.

Key Features of Our Combination Rolling Mill

Versatility in Rolling Operations

One of the most significant advantages of our combination rolling mill is its versatility. It can handle various types of metals, including steel, aluminum, copper, and their alloys, making it suitable for a diverse range of industries such as automotive, aerospace, construction, and jewelry making.

Whether you need to roll flat sheets for building panels, shape bars into specific profiles for machinery components, or draw wires for electrical applications, our machine has you covered. It offers multiple rolling modes and adjustable settings that allow you to customize the rolling process according to your specific requirements. For example, you can easily switch between flat rolling and shape rolling by simply adjusting the roller configuration and settings on the control panel.

Precision and Accuracy

Precision is crucial in metalworking, and our combination rolling mill delivers outstanding results in this regard. The rollers are meticulously machined to extremely tight tolerances, ensuring that the metal is rolled to the exact dimensions you specify. This level of precision is essential for applications where accuracy is of utmost importance, such as in the production of precision-engineered parts for the aerospace industry or high-quality jewelry pieces.

The machine also features advanced measurement and control systems that continuously monitor the rolling process and make real-time adjustments to maintain the desired thickness and shape of the metal. This not only guarantees consistent quality but also reduces waste by minimizing the need for rework due to inaccurate rolling.

High-Quality Construction

We understand that durability is a key factor in any industrial equipment, and our combination rolling mill is built to last. It is constructed with high-quality materials, including a robust steel frame that provides excellent structural integrity and stability during the rolling process. The rollers are made from hardened alloys that can withstand the high pressures and friction involved in metal rolling, ensuring a long service life without the need for frequent replacements.

In addition to its sturdy construction, the machine is also designed with safety in mind. It comes equipped with safety guards and interlocks that protect operators from potential hazards, such as getting caught in the rollers or being exposed to moving parts. This ensures a safe working environment for your employees while they operate the machine.

Adjustable Rolling Parameters

To meet the diverse needs of different metalworking applications, our combination rolling mill offers a wide range of adjustable rolling parameters. You can easily control factors such as the roll gap, rolling speed, and pressure applied during the rolling process. This flexibility allows you to optimize the rolling operation for each specific metal and task, resulting in the best possible outcome.

For instance, if you're working with a softer metal like aluminum, you may need to adjust the roll gap and pressure to prevent excessive deformation or damage to the metal. On the other hand, when rolling a harder metal like steel, you can increase the rolling speed and pressure to achieve the desired reduction in thickness and shape transformation.

Energy-Efficient Design

In today's energy-conscious world, our combination rolling mill features an energy-efficient design that helps you save on operating costs. It incorporates advanced motor drives and power management systems that optimize the use of electricity during the rolling process. By reducing energy waste, our machine not only benefits the environment but also provides you with significant cost savings in the long run.

The energy-efficient design also contributes to the overall stability and performance of the machine. It ensures that the motor operates smoothly and consistently, without overheating or experiencing power fluctuations, which can affect the quality of the rolling operation.

Applications of Our Combination Rolling Mill

Automotive Industry

The automotive industry relies heavily on metal components that are precisely shaped and formed. Our combination rolling mill is used to produce various parts such as body panels, chassis components, and engine parts. It can roll flat sheets of steel or aluminum into the desired shapes for car bodies, and shape bars into profiles for suspension components or engine brackets. The precision and versatility of our machine make it an essential tool in the automotive manufacturing process.

Aerospace Industry

In the aerospace sector, where the highest standards of quality and precision are required, our combination rolling mill plays a vital role. It is used to produce components such as aircraft wings, fuselage sections, and engine turbines. The ability to roll metals to extremely tight tolerances and transform them into complex shapes is crucial for ensuring the structural integrity and performance of aerospace components. Our machine can handle the specialized alloys used in aerospace applications and deliver the necessary precision and quality.

Construction Industry

The construction industry uses a vast amount of metal products, from structural beams to roofing sheets. Our combination rolling mill is employed to produce these metal components with ease. It can roll flat sheets of steel or other metals into the desired thicknesses for building panels, and shape bars into profiles for structural supports. The versatility of our machine allows it to adapt to the different requirements of various construction projects, whether it's a small residential building or a large commercial complex.

Jewelry Making

In the jewelry industry, precision and aesthetics are of utmost importance. Our combination rolling mill is used to roll precious metals such as gold, silver, and platinum into thin sheets for making jewelry pieces. It can also shape wires for setting gemstones or creating intricate designs. The ability to work with small amounts of precious metals and achieve high precision makes our machine a valuable asset in the jewelry making process. Technical Specifications

Rolling Force Capacity

Our combination rolling mill is available in different rolling force capacity options to suit various applications. The rolling force capacity ranges from [X] tons to [Y] tons, depending on the model. A higher rolling force capacity is required for rolling thicker and stronger metals, while a lower capacity may be sufficient for lighter metals or thinner sheets.

Roll Diameter and Width

The roll diameter and width also vary depending on the specific model of our combination rolling mill. The roll diameter affects the contact area between the rollers and the metal, which in turn influences the rolling process and the final product quality. The roll width determines the maximum width of the metal sheet or bar that can be processed. We offer a range of roll diameters and widths to accommodate different metalworking requirements.

Maximum Sheet or Bar Thickness

The machine can handle maximum sheet or bar thicknesses ranging from mm to mm. This flexibility allows you to process both thin and thick metals with ease. Whether you need to roll a thin aluminum foil or a thick steel bar, our combination rolling mill has the capacity to handle it.

Motor Power

The motor power of our combination rolling mill is another important technical specification. It ranges from kW to [J] kW, depending on the size and capacity of the machine. The motor power determines the speed and force with which the rollers rotate, which is crucial for efficient and effective rolling of the metal. A higher motor power is required for machines with larger rolling force capacities and higher processing speeds. After-Sales Service and Support

Installation and Commissioning

When you purchase our combination rolling mill, we provide comprehensive installation and commissioning services. Our team of experienced technicians will travel to your site to install the machine and ensure that it is up and running smoothly. We will also conduct initial tests and calibrations to make sure that the machine is operating within the specified parameters. This ensures that you can start using your combination rolling mill right away without any hassles.

Training

We understand that proper operation and maintenance of the combination rolling mill are essential for its long-term performance. That's why we offer training programs for your operators and maintenance personnel. Our training courses cover all aspects of the machine's operation, including control panel operation, routine maintenance tasks, and troubleshooting techniques. This ensures that your team is well-equipped to handle the machine and keep it in optimal working condition.

Spare Parts and Maintenance Support

We maintain a large inventory of spare parts for our combination rolling mill. This ensures that in the event of a component failure, we can quickly provide the necessary parts to minimize downtime. Our maintenance support team is also available to assist you with any maintenance issues that may arise. We offer regular maintenance contracts to help you keep your machine in top shape and prevent unexpected breakdowns. Why Choose Our Combination Rolling Mill?

Quality and Reliability

Our combination rolling mill is built to the highest standards of quality and reliability. We use only the best materials and advanced manufacturing techniques to ensure that the machine can withstand the demands of continuous operation in a harsh industrial environment. With our combination rolling mill, you can be confident that you are investing in a piece of equipment that will deliver consistent and high-quality results for years to come.

Customization Options

We understand that every metalworking operation is unique. That's why we offer customization options for our combination rolling mill. Whether you need a specific rolling force capacity, a different roll diameter, or a custom-designed control panel, we can work with you to create a machine that meets your exact requirements.

Competitive Pricing

We strive to offer our combination rolling mill at competitive prices without sacrificing quality. We believe that affordability is an important factor in helping businesses of all sizes access the latest in metalworking technology. Our pricing structure is designed to provide you with excellent value for your investment, making it easier for you to expand your metalworking capabilities.

Industry Experience

With years of experience in the metalworking industry, we have a deep understanding of the challenges and requirements of our customers. We have used this experience to design and develop our combination rolling mill to meet the specific needs of different industries. When you choose our combination rolling mill, you are choosing a partner with a proven track record of success in the metalworking sector.

If you are looking for a reliable and efficient combination rolling mill to enhance your metalworking operations, look no further. Our combination rolling mill for sale offers the perfect combination of quality, versatility, and affordability. Contact us today to learn more about our products and how we can help you achieve your metalworking goals.