How to Make Nata De Coco at Home, Fresh Menu and Favors to Open Fasting

PEKANBARU.- That coconut water is thrown away useless for long time. There are people who fun to count how nian coconut water is thrown away it? Apparently there are 2.4 million liters a day, if true coconut production throughout Indonesia Raya only 2.700 million grains a year.

Water discharged (before the flesh is used) is only 900 million liters a year. On paper is blurred, it's only 2.4 million liters a day.

This amount is meaningless, if we can not imagine how much (actually) 2.4 million liters it. But if we are casually contemplating: with how many tank trucks that amount can be transported?

So, the waste of coconut water there are four hundred trucks a day, if each truck is used to carry 6,000 liters.

Can not, four hundred trucks a day be used as food, such as coconut water in the Philippines, made nata de coco (export quality for Europe)?

Yes, if you want.

Nata de coco is a solid material such as gelatin (but more supple) or like frost (but more soft), transparent white.

It used to be imported into Indonesia as an ingredient in syrup, packaged in bottles, and sold in some capital supermarkets.

But lately, the M and M industries (formerly called P & D) we can already make it ourselves, and enter the supermarket, although it's still not regular, 'rush'.

Because it is obtained from coconut water, the solid white material that is chewy is also called coconut juice, although it is only the water sari only. Usually it is served as a mixture of fruit bowl and fruit cocktail, after lunch, to 'wash the mouth'.

How is it possible, from the liquid coconut water can form a solid clot! None other than acute bacteria Acetobacter xylinum, which we deliberately enslaved.

This bacterium is able to convert glucose sugar (about 5%) in the original coconut water into cellulose (cellulose), a substance similar to glucose.

But if glucose is theorized from a series of molecules C6 H, 2 O6, then the resulting cellulose is considered as C6, H10 O5. It is the same formula with starch substances. Only the arrangement of atoms in the molecule, and the arrangement of molecules in different sets of macromolecules.

Cellulose can strengthen the cell walls of plants that had been soft, become more supple, so that it can protect the contents of the cell. (Then it's easy to remember it, it's called cellulose).

Strangely, the Acetobacter xylinum bacteria make cellulose not to strengthen its own cells, (its work is not attached to its body), but merely because it wants to derive energy from the process of reshuffling the molecule of glucose into the cellulose molecule.

The energy that arises used to overcome the process of exchange of substances in the body.

Although both carbohydrates with starch and glucose sugar, but cellulose is more difficult to digest. For example, cellulose from fibers coarse green skin. Sometimes even some can not be digested at all, like cotton fibers that cover the seeds, for example.

Wow! What happens if we eat cellulose from nata de coco?

Actually, the cellulose that enters our body with daily food is also not small. It is okay! Vegetables and fruits such as long beans (shortened ones), emping melinjo, kangkung cah, jackfruit, all contain cellulose that we swallow everyday (and that's okay).

This material even plays an important role as a driver of our food digestion. Because it is a subal that enlarges the volume of soft food ingredients that have entered the intestine, the cellulose stimulates the intestine to move the food mass pushing toward the 'back door' smoothly. Not jammed in the center of the restroom.

Do not get tired

To obtain nata de coco as a result of bacterial fermentation of Acetobacter xylinum, we may start with 50 liters of coconut water, or 2 ½ 20 liters of plastic jellies. This is enough to make eighty bottles (jam) nata de coco.

Read also: Open Fasting Without Dates Less Afdol, What If Fasting Months Fall Outside The Season Dates?

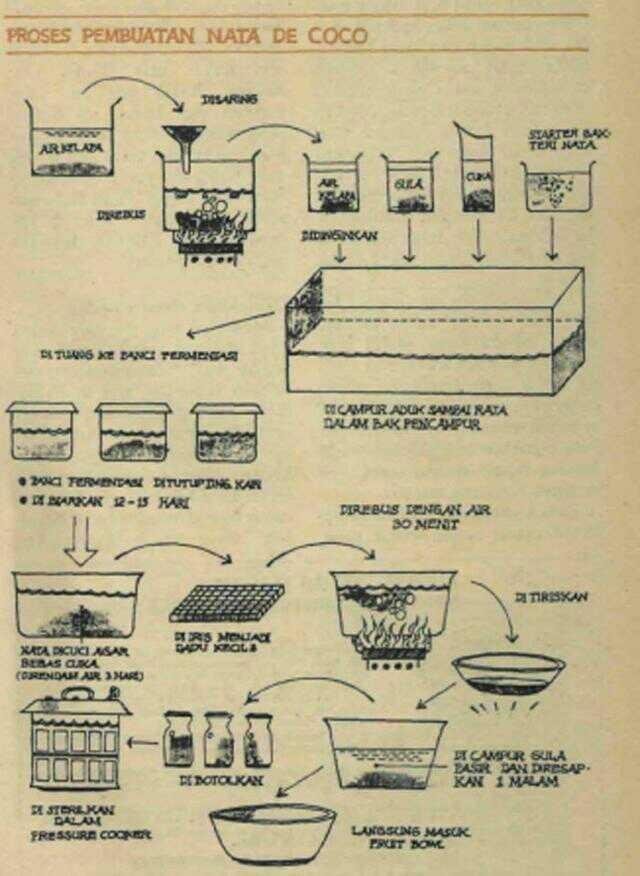

Once filtered with mori cloth (to be completely free of dirt), coconut water was first boiled until boiling first. That is no other so that the seeds of bacteria of various kinds that nebeng in the water can be all utterly crushed.

So do not mess up the fermentation process that we want to do with the culture of Acetobacter xylinum pure later.

Once cooled, the clean coconut water is poured into the mixing bath, and sprinkled with sugar (preferably dissolved in a small amount of clean water first) of 20 kg. Then entirely sprinkled with 5% vinegar as much as 1 liter.

This 5% vinegar is sufficiently concentrated to create an acidic atmosphere for Acetobacter, in order to work diligently to break sugar molecules into cellulose molecules.

After stirring until blended with a plastic stirrer that has also been sterilized, fluid sprinkled with starter (prickly) bacteria nata, Acetobacter xylinum, then stirred constantly until the cultivator was evenly mixed.

The liquid is then poured into smaller shallow containers (eg a 20-30 cm diameter pan as high as 20 cm, or other container of a glass of that size), which acts as a fermentation pt. But pour it not more than 15 cm in height (or inside).

This 15 cm liquid is intended to be involved in the process later only the fluid as needed. Not much will be wasted as a liquid down.

The place of fermentation should be sealed with a cloth, so as not to be invaded by ants or other insects, but still be penetrated by the air needed by bacteria. Thus, solids will form slowly, near the surface. That even if the container was placed on a free shelf-senggolan flat.

The longer the layer of the nata becomes thicker (and thicken it downward), until it can no longer be held back by the fluid underneath. Then crack.

But of course, before the ambrol, nata should be harvested. That is after 12-15 days since the liquid is poured first.

To remove the vinegar that remains attached, nata de coco should be soaked for three days in clean water, and every day renewed the water.

After the vinegar free, nata sliced into ½ x 1 ½ cm dice, or 1 ½ x 2 cm, then boiled for 30 minutes. Certainly sprinkled with enough water so as not to burn.

The purpose of boiling it is that the colloidal fluid formed from the liquid remains gel-like gelatin (gelatin) due to the heated. Not in the form of a continuous sole, as before heated, which can at any time melt back.

With boiled it also, nata that formed so free of bacterial decay.

After boiling for 30 minutes, the nata gel is drained (dried over a sieve, for the liquid to drip down, to dry the wind), then mixed with sugar as much as the weight of nata.

Then left for one night, so that sugar could seep into it.

Sterilized to be durable

The next day, the sweet nata was put into a jam bottle to be sterilized in a pressure cooker pan. It should be packaged in a bottle, so it can be sold in supermarkets that cold room.

Already, the jar of jam to be used should be washed first with soapy water, and boiled with hot water. The lid (which is generally made of strong thick plastic) is also treated similarly.

Nata that have been put into a clean bottle usually given liquid sugar syrup, as a preservative. But the syrup should be hot. So the time it takes to sterilize does not need to be long-winded, because the syrup itself is hot.

This syrup should soak the nata in such a way that the liquid surface is still ± 1 cm below the bottle cap.

Why should not it be full at all? No other so that if the liquid soak it later expands after heated in a pressure cooker he will not press the bottle cap until broken, because there is no air cavity as an insulator.

While filling the nata into this bottle, the pressure cooker pan (of course large) has to be filled with water and heated over the fire, until the water is boiling. Only then he is ready to be filled with bottles that have been closed.

The pot has some sort of syringe or rack to place the bottle. Boiling water should soak the bottle on this shelf altogether, until the surface coincides with the surface of the bottle cap.

Once the pressure cooker's pans are closed tightly, it is heated again until the water inside boils (again), with the air vents kept open. The sign that the water is boiling is that there is smoke coming out through the ventilated open ventilation.

Smoke was allowed to hiss out first for 5-10 minutes. Then ventil may be closed.

Thus, the vapor pressure in the pan will rise until it raises the temperature as well, which can be read on the installed thermometer. If the temperature has reached 120 ° C, then from then on we have to calculate the 30 minute drilling period.

After that, the breaking was stopped (the pan removed from

Starter of bacteria used bacteria can be purchased at Pusbangtepa (Center for Food Technology Development), Campus IPB Dermaga, Boxes 122 Bogor.

But so as not to repeatedly facing Pusbangtepa, starter that we get it should be partially self-breed, in grated pineapple fruit that is ripe. Breeding takes ± two weeks.

Every time we want to make nata de coco from eight glasses of coconut water, we only need to provide half glass of grated pineapple result of this two weeks only.

The work of the material becomes nata, then the same is the way that has been expressed in advance. Namely after boiled and mixed with sugar and vinegar, infected with bacteria from pineapple.

Making Nata de coco

This 'home' coconut water also needs to be poured into a fermentation container (small pan only) and allowed to stand for 12-15 days, complete with a cloth cover as necessary.

The result is also washed and cut into small pieces, then brewed briefly before it begins to sweeten. It's just that the results that have been in the form of this sweet dice did not have to be bottled, but just put in fruit bowl, fruit cocktail, or other, which is programmed as a dessert.

(Written by Slamet Soeseno, as published in January 1984 issue of Intisari magazine)

Pekan baru hom,