Upgrading a Chinese K40 Laser Cutter to USA Brand-Name Quality

Previously I mentioned my Chinese K40 40w laser and how I was planning some upgrades. This is the first follow up - this weekend I fitted a couple of them and did some test cuts!

- Smoothie board replacement for the main GRBL controller board

- Activated Carbon filter

- Lightburn software

Can the upgraded machine achieve USA Brand-Name laser quality, at 1/10 the price? Let's see ...

Smoothie Controller

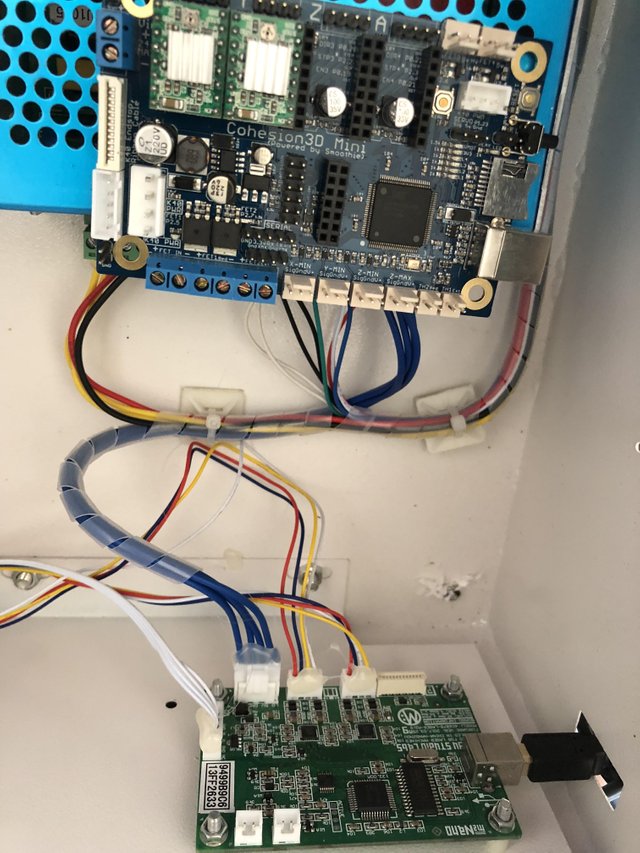

I bought my controller and software license from Cohesion3D.

This board is a 1:1 replacement for the existing electronics, but offers much better performance. While the original board "works", using my upgrade I have more control, using PWM to fire the laser, giving the opportunity for greyscale rather than simply power the laser on/off.

Technology-wise you can see a visible improvement, due to the higher performance processor and more advanced firmware (lots of math that I don't understand!).

It took me minutes to swap out the boards without checking instructions. Unfortunately, I did have to swap one stepper around due to the controls driving the laser head in the wrong direction ;)

This upgrade alone has seen a huge increase in capability and performance. Highly recommended!

Air Filter

This was a bit more of a let-down. Not because of the principal, or even necessarily the product, but my experience with my filter specifically was sub-par.

When I opened the box it was full of carbon, the packet had burst, plus the filter itself appears used. I will contact Amazon.

If I don't manage to get a replacement or instructions to put it right, I may just go with a longer hose. I'm not keen on the idea of making a whole in my garage wall right now.

Software Upgrade

I'm a big fan of Open Source, but there are times when free software just doesn't ... um ... cut it ;)

LightBurn will appear familiar to people who are accustomed to the software that often comes with laser cutters, but this software is in English and actually works.

So, while it operates in a familiar way, it produces better results.

Previously, I had been using InkScape and a plugin, then a GRBL sender. I will probably continue to create my vectors in InkScape, but this software handles SVG files well, and allows you to finely control speeds and power.

Definitely check this software out.

Next Upgrades

Next time I will work on the lenses, mirrors, air assist, and try and resolve the lack of Z axis/focus ...

Posted from my blog with SteemPress : https://makerhacks.com/k40-laser-upgrades-part2/

Laser cutters are great! :) Thanks for sharing!

I've been thinking about buying one for years, still not decided, mostly worried about the fumes...

BTW, Autodesk Fusion 360 supports laser cutters... It's free for hobbyists and small businesses. Give it a try! It is definitely better than Inkscape with that plugin. You might even like it better than LightBurn...

Yeah you have to be careful. I just ordered a loooong hose so I can put the fumes outside, and an in-line fan to suppliment the extractor.

I've used Fusion for CNC, but I like the layer support in LB. It's a personal thing because I first learned on a Leetro/mach based chinese machine that used LaserCut.

When we upgraded to a trotech using a printer driver I felt a bit lost ;)

You know what would be a great topic for one of your future posts? Laser cutting for dummies! There seems to be a lot of information about laser cutters on the Internet, but it's hard to tell which is false advertisement and which is true. Most of the videos I've seen seem to be speeded up, no one ever talks about laser cutting out of focus because of uneven or bent stock sheet.

It would be great if someone with your experience could tell us the truth, share first-hand knowledge! :) Like to what depth can you realistically cut on a 40W CO2 machine? Will it cut 6 mm plywood? What would be the speed? Which is better - multiple fast passes or only one slow pass to full depth? How soon CO2 tube will degrade and will it degrade even without use? Are there any good and bad brands or types of protective glasses? What materials you can cut, and what you should not ever try cutting of a laser cutter...

I look forward to your next post :)

Ooh good idea, yeah I will look at doing that when my day job work settles down :)

Oh this is a good news that K40 Laser are update in part2.

I see K40 Laser in part 1.

I will see it for first time.

Thanks for sharing sir @makerhacks.

Join our Discord Channel to connect with us and nominate your own or somebody else's posts in our review channel.

Help us to reward you for making it ! Join our voting trail or delegate steem power to the community account.

Your post is also presented on the community website www.steemmakers.com where you can find other selected content.

If you like our work, please consider upvoting this comment to support the growth of our community. Thank you.