What is going on with that CNC mill?

Well first of. It has proven to be a lot more work than I thought.

First there was the software. I downloaded fusion 360 and learned how to set up a relief milling job, but never reaaly liked it. first because of the licensing thing, but also because if you have the free version, everything happens in the cloud apparently (maybe I just dont know how to do it locally)

then I stumpled upon camlab. It is based on Kiri:Moto and is also webbased. It is however much more simple to use than fusion360 and has a premade shapeoko profile.

The gcode generated by it, can be used directly with the shapeoko cam software. Thus I was satisfied I had a working pipeline that was to my liking and that would work. Time to mill ! or not -

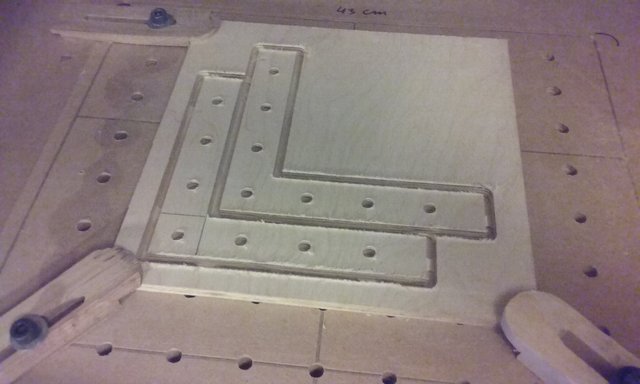

To be able to secure my work I needed some holders. Traditionally these are made on a cnc so that would be my first real project.

Holders can be grouped into two kinds, the ones that push down and the ones that push from the side.

I made a few of both. but I needed some holders for this as well - hm chicken and egg problem, so I made 4 holders by hand that could work for a short while. They where made from some scrap pinewood I had and worked alright. With these I could make 2 oak holders and then after that 2 angular holders . These are used to make sure the x and y axis are aligned when you insert a new piece of material.

With the two angular holders finished I could start making some circular holders that would fit on top of the angular ones. That way, they can both hold the material from the side and push it down from above. the circular ones are 40 mm across, while the angular one is 30 mm across. That way the circular holders will have a 5 mm lip. to use the material more effectively I decided to also make a beer coaster.

I chose one of the designs by @katharsisdrill that you can see here and made a tool path using a v-bit.

V-bit tool paths work by letting the cad program choose the depth of the cut to control the width of the cut.

Unfortunately the v-bit I have is not really good quality, it is both too flat at the tip (almost 2mm broad) and not sharp enough for precision work. It was part of a cheap set of router bits I bought to make sure I had something to use when i got the mill. They are alright for classic woodworking stuff, but for precision work, they are really not up to par. Even so I think the result in this case was acceptable

At least I got to check my holders and I got the chance to see what the mill can do. The coaster itself is also still usable even if the pattern is a bit blurry

I milled it from 9 mm birch plywood. Not the prettiest wood, but cheap and fairly sturdy, and not bad looking I think.

It is better than most plywoods at least. It is nice for experimenting with, because the result is good enough for using and the cost if it doesnt work isnt too much.

Some of you may have noticed the holes in the wasteboard of the mill and wondered if they were there when i bought the machine. No they werent. I have also made them using the mill, but that will be another post.

until then.

Im EvilHippie, a compulsive creative and jack o' trades. If you want to know more about me, check out my introduction post here

If you like what you see, feel free to upvote, follow and resteem

or you can check out my accounts on these sites:

Looks cool, I like the result :) Those holders sure came in handy !

Thanks. it is amazing how much it means to be able to hold down the workpiece effectively.

Congratulations @evilhippie! You have completed the following achievement on the Steem blockchain and have been rewarded with new badge(s) :

Click here to view your Board

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Hello @evilhippie, thank you for sharing this creative work! We just stopped by to say that you've been upvoted by the @creativecrypto magazine. The Creative Crypto is all about art on the blockchain and learning from creatives like you. Looking forward to crossing paths again soon. Steem on!