How to not get ripped off and make junk – Big trouble in little China

I want to talk about the common things that people worry about when trying try to source from China. It can be pretty intense. First , doing business with someone very very far away feels strange. How can you possibly make this work ?

At the same time, it is different then doing business in your home country. There is a lot to take in. I have been doing it for 10 years, I am always learning something new.

So let me share some of the common feelings and problems that people enocounter when doing this business in China.

1.Don’t know where to start

In the beginning it is very daunting. There are so many questions.

How do I make a product?

What is this product made out of and what I do I know about that?

How do I start finding a supplier?

How do I know if the quality will be good?

There is a lot of doubt here. Just like anything, starting will get you the answers you need.

2.Nervous they are being taken advantage

This is because you are not armed with the tools to protect yourself. For the sake of ease, you are letting someone else call the shots. This is a sure fire way to get something you don’t want.

The tools you need are called knowledge and experience.

3.Doing a lot of hard work for just an ok product

Again, it is because there is not a plan. You are trying to put out all the fires at once.

The goal here is to prevent fires from even starting. Once you have a plan, you are just on maintenance mode and making sure your project is meeting its goals

4.Missing important timelines that cost real opportunities and business

This is a sure fire way of killing your business. While you have been putting out fires, opportunity slips by you AND you are out money.

This is the worst of the worst and puts your business at risk

5.Giving up because it does not produce the results you want.

Putting in the time and hard work will get you there, just not very fast. This can kill any momentum you may previously had. So what happens when we face mounting adversity? Possibly revert back to the previous method that worked for you. Which might mean fire fighting.

6.Using a middle man/ agent to do the work, but not getting what you want out of the relationship.

First, using an agent is not all bad, IF they provide a service that is valuable. I know a lot of people that are just caught with an agent because they think they have no choice OR boxed themselves into ONE supplier and that is NO good.

I see this a lot. People have one person that holds the keys to their business. This limits your ability to make important decisions and make changes when YOU need to.

Stop fire fighting, start managing. The common thread of all these is a lack of understanding and control, which leads to real business problems

3 Core strategies for manufacturing your goods in China

Here are our 3 Core Strategies we think about for every project to help solve these common problems and get you in control. Let’s start general, later we can get down to the devil. ( details that is )

- Prospecting

- Setting up for success

- Understanding manufacturing/ getting your product

Prospecting

Prospecting is more than just finding a product or a supplier. It is about setting up a Roadmap to follow. A clear path to a goal you would like to achieve for a certain project.

But what does that mean?

For Prospecting, think about these items:

- What is your product

- What is your time frame to get this complete or specific goals?

- What type of project is this? Is it a One time order OR a long term relationship with a supplier.

- Finally, think about what matters to YOU.

Cheap price and great quality all I need, Jamon! ... So does everyone else and it is not that easy to obtain. T here is a lot more to it then that

I suggest the 4 items to think about to get the right product and supplier.

- Quality

- Quantity

- Price

- Speed

These are going to be ground rules you operate by. This will help you to move forward to find products and suppliers.

Setting up for success

Once you have written out the items for yourself from the prospecting sections, you now move on to figuring out what items you need to get in line NOW so you can move easily in the future.

Now that you know what your product is, you need to know the specifications of that product. If we are talking about whisky stones for example, you need to know some of these:

- What material do you want it to be?

- How many colors do you need?

- What type of accessories you need?

- How many you need?

- Any special regulations for these?

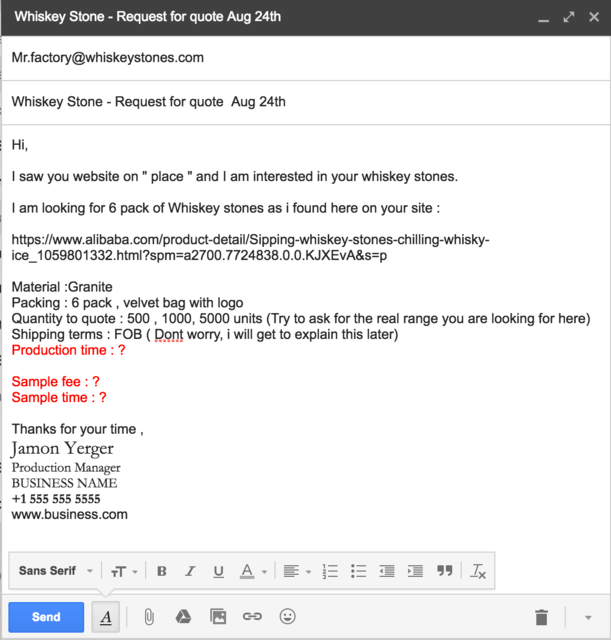

Take all these details, place them in and word or excel document later for easy referencing. You will need these specifications to send in your first email to the supplier.

Which leads us to our next step, make a template email with your requests to make your 1st contact easy and efficient.

Remember : Kiss – Keep it simple stupid

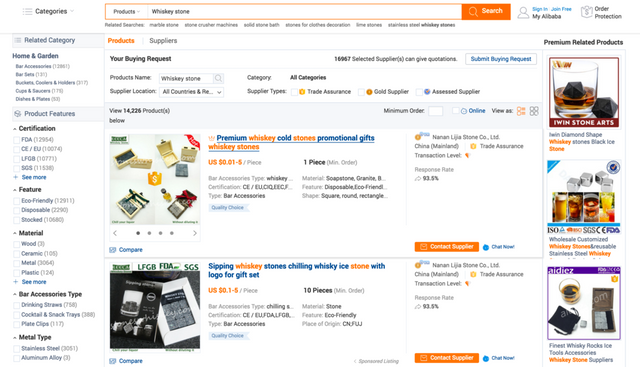

Now is the time to have a look on Alibaba or Made in China to look for your product. You now know what you are looking for, how many and what timeline you need achieve. Feels pretty good at this point right?

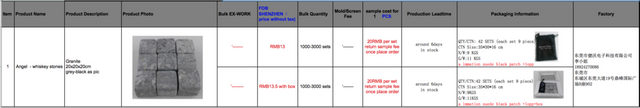

You should be getting some quotes back. This a great starting point! You should be taking all the quotes you are getting back and putting them in an excel sheet for you to compare. It will be important that you are able to compare these suppliers and prices easily. This will help you make the best informed decision as possible.

Understanding manufacturing/ getting your product done

This starts with getting a sample made of your product. This takes time and is also vital to your future production being as smooth as possible. Remember FAST IS BAD, STEADY IS GOOD. You got to keep repeating this mantra. All of the major mistakes we have made are from going to fast. Nothing good comes from rushing a complicated project.

Getting a sample made of your product could range from simply adding a logo and changing some packing items to completing making something custom and taking 2 months to make. BUT This should have been found out in Prospecting and Setting up for Success. In the end, you should get a perfect or almost perfect sample BEFORE you put down a deposit on a large order. You need to make sure YOU and the supplier all understand the project and what potential problems it may have.

At this point, start thinking more about Quality control. Just think, you just did:

- The first leg of QC by cross comparing your suppliers and quotes.

- You figured out what supplier(s) you are going to continue with.

- Making a specification sheet for your supplier to follow about your product.

- You just confirmed your sample to be correct OR what need to be improved.

It is important we take that same diligence in to bulk production.

You should be checking in with your supplier often and confirming important milestones of your production.

Like this girl:

Is the bulk material right? Did you get this part on time so we can meet our final date? Can I see Inline production pictures of the goods, so I can scan for mistakes or improvements we can make?

Don’t be shy to try to talk to your supplier often and ASK questions. IF they are not answering your questions now, they will not in the future. You will need to find a better partner if this is the case.

Let’s go through it one more time. I went pretty fast back there:

Prospecting

What is your product?

What is your time frame to get this complete or to hit certain goals?

What type of project is this? Is it a one time order OR a long term relationship with supplier.

4 items to think about what is important to you:

- Quality

- Quantity

- Price

- Speed

Setting up for success

- Understand the specification of your product.

- Make a specification sheet and record those points to share with suppliers and keep record for yourself.

- Create template email to make first contact easy with many suppliers.

Understanding manufacturing/ getting your product

- Understand what it means to make your first sample and how much it cost.

Understand how much time you need to complete this VITAL step. - FAST IS BAD, STEADY IS GOOD

- Expand and continue to think how you will QC

- Your supplier communicating well with you? Are you comfortable continuing in this way in the future.

A lot of meat & potatoes here. I will have another tomorrow to give some examples on the ideas above. Dig in!

Honeslty one of the best articles I've ever seen on this anywhere, and not just because it has one of my fave movies in it and tells us about your "whiskey stones". It's because it is unpretentious, straightforward, and comes from hard experience. It also shows you follow your own advice--KISS. Nice work, man.

Thanks Thorny

Much appreciated! Try to take the mystery out of it all.