CE licensed natural fertilizer pellet making device

The organic fertilizer pellet making device is utilized to powder numerous natural materials after fermentation. Before granulation, the raw products do not need to be dried and grated, as well as round granules can be refined directly with active ingredients, which can save a great deal of power.

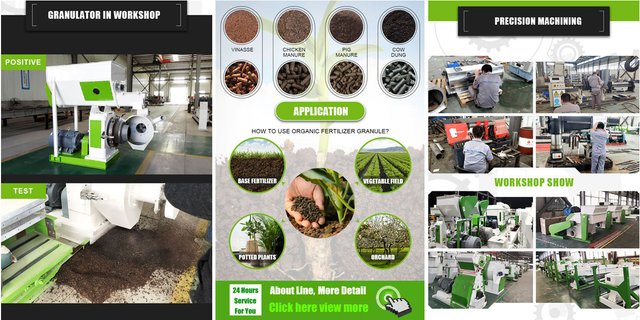

The organic plant food pellet making maker is made up of a reducer, a combining, an electrical motor, a feed port, a discharge port, a frame, a cylinder, and also a bearing. It is commonly used in the granulation of fermented plant foods such as livestock and chicken manure, trash sludge, composting plant foods, straw rice husks, cassava residues, a glass of wine trough deposits, green manure cake fertilizers, peat, and also soil miscellaneous fertilizers.

Related post: chicken manure pellets machine

The shell of the natural fertilizer production machine is made from thick smooth steel pipeline, which is tough and also sturdy; combined with a secure base, it makes its procedure extra stable. It is selected as the ideal product by the bulk of individuals.

1. Review of organic plant food pellet making equipment

This organic plant food pellet making maker is a kind of natural fertilizer pellet mill for processing grainy resources into granules, which appropriates for high nitrogen material items such as organic as well as inorganic compound plant foods. This natural plant food pellet making maker is made up of a frame, a drum, an internal mixing tooth granulation device, an inner transmission mechanism, an outer transmission system and various other parts.

Related post: organic fertilizer pellet making machine

a. The structure is welded with thickened network steel.

b. The drum is welded by enlarged steel plate and adopts the kind of a drum natural fertilizer pellet making maker.

c. The granulation system embraces the tooth stirring granulation technique.

d. The internal drive embraces the soft link approach of the combining.

e. External transmission embraces cast steel gear meshing for transmission.

2. Organic plant food pellet making equipment item attributes:

The pellets produced by natural plant food pellet making equipment are spherical.

The natural web content can be as high as 99%, understanding pure organic granulation.

Using the function that natural pellets can grow up with each other under appropriate force, no binder is required throughout granulation.

The granules are firm and can be sieved after granulation, lowering drying power usage.

The organic matter after fermentation does not require to be dried, and also the moisture content of the raw material can be 20-40%.

Related post: organic fertilizer production plant cost

3. Advantages of organic plant food pellet making device

The principle of the organic fertilizer pellet making equipment is easy, the granulation rate is quickly, and also the fine powder material is constantly mixed in the equipment by using the mechanical mixing pressure of high-speed turning and the wind resistant pressure generated therefrom.

High granulation top quality, this organic fertilizer pellet making device is especially suitable for the granulation of light as well as great powder products. The finer the basic bits of the great powder product, the greater the sphericity of the bits as well as the better the quality of the ball.

No binder is needed, and the natural pellets can be installed with each other under the activity of the force, as well as no binder is called for throughout granulation.

Sturdy and also durable. The organic fertilizer pellet making equipment tooth removal is strong and durable, as well as has a splitting and blending result on the product.

Related post: horse manure pellet machine

4. Installation and debugging of fertilizer pelletizer:

( 1) Installation: This series of natural fertilizer pellet making equipment generally have the adhering to components after leaving the manufacturing facility:

① The main body of the disc granulator, the main body consists of the framework of the framework, the modification part as well as the granulation disc; make the structure according to the tools structure map given by the fertilizer pelletizer supplier.

② One main reducer, the input shaft is geared up with a wheel, and also the output shaft is geared up with a pinion;

③ One bottom line electric motor and one sheave; place the organic fertilizer pellet making maker on the ready-made equipment structure, and then bonded the tools and the ingrained iron externally of the structure with each other. Before checking the device, pay attention to the turning instructions of the maker, the cylinder body as well as the main shaft rotation instructions are the same.

④ Assistance granulation disc device, consisting of one primary shaft, two sets of roller bearings, and 2 sets of bearing seats;

⑤ Accessories: V-belt, edge bolts.

Related post: cow dung manure making machine

( 2) Debugging: The raw materials used by this organic fertilizer pellet making device are different. Generally, it has been changed before leaving the manufacturing facility, as well as passed the strict quality and technical assessment and accepted the certified factory, but it still needs to be adjusted because of on-site maintenance or issues after operation and usage.

5. Operating treatments of plant food pellet machine

Prior to starting the natural plant food pellet making machine, first check whether the screws hang, and whether the rolling belt, supporting roller, pinion equipment, and also big ring equipment are covered with butter.

Inspect whether there are any sundries or products inside, and clean it up in time.

Inspect whether there are sundries wrapped around the interior stirring and also granulating teeth, or there are too many bonding materials, and they must be cleaned up in time.

After the natural fertilizer pellet making machine is begun, the product needs to be uniformly fed. If it can not be big or little, it will affect the granulation and also damage the life span of the electric motor.

Throughout the granulation process of this natural fertilizer pellet making equipment, it is necessary to manage the thickness of the product, the percentage of the material, the thickness of the material, and also the dimension of the dampness of the product. Furthermore, the dimension of the wetness of the material is symmetrical to the size of the particle.

When leaving work, the product inside the maker should be drained easily to avoid load from sticking to the inside of the organic fertilizer pellet making equipment.

6. Maintenance of organic plant food pellet making equipment.

On a regular basis examine whether the screws of numerous parts of the devices are loose.

On a regular basis inspect whether there is oil in the revolving and rolling parts of the organic fertilizer pellet making machine.

The reducer must be changed with brand-new oil every 6 months.

Related post: https://www.pellet-richi.com/wood-pellet-machine/chicken-manure-pellet-machine.html

Regularly inspect whether the internal wall surface of the cylinder is stuck to the product, as well as the front end of the mixing tooth is abided by the product, which must be taken care of in time.

Regularly check the distance between the cyndrical tube and the stirring teeth, and also the range ought to be 3mm ~ 6mm.

The range between the cylinder body as well as the mixing teeth is too huge to develop granules. The organic fertilizer device mixing tooth head at the front end of the mixing tooth ought to be readjusted in time. If the stirring tooth head of the natural fertilizer pellet making equipment is seriously used, the new stirring tooth head should be changed in time.

For details please contact: Richi Pellet Machine

WhatsApp:86 138 3838 9622

Email:[email protected]