7 Years in the Making - Building the Perfect Engine [Super Extended Version]

I don' t think any steemit logo has ever rested on the idle switch of an engine :). With that out of the way welcome to my complete journey of how I built an engine, installed it and built a matching exhaust system. This will result in sth like this:

Looks small and thin right? Those were my first thoughts as well. This is a signature BMW straight 6 engine, 2 valves, one overhead camshaft and electronic engine management, internal code M20. Currently good for around 200bhp and propelling the little E30 sometimes called 'matchbox' sometimes called 'bear' and sometimes simply 'THE' BMW to around 150mph.

As part of my series '7 years in the making - Rebuilding and Restoring a 30 year old BMW' this is a special dealing only with the engine of that car. It combines the engine relevant sections of parts 2 and 3 and extends heavily on details and pictures and finishes with the final welded stainless steel exhaust setup as well as complete listing of all components.

Planning

Maximum performance without compromising daily usability or engine durability over the long haul was the goal.

So first thing to deal with was finding someone who can actually build the engine and preferably has some experience with the M20. My mechanic referred me to a guy who's been building engines for 30 years and used to build race engines for endurance sport. We went to this farm out in the countryside with a small garage attached to it. When I saw the Denso hat the guy was wearing and listened to him speak for 5 minutes I was sold. He had enough tools in that place to build a f***ng F1 engine let me tell you.

When I told him that I planned to build a 2.7L M20 with all new components he took a good look at me and literally went: "you're the first person to walk into this shop who wants me to build this engine since 1997". Not sure how that made me feel but at least then I knew he's done it before.

He asked me about the head how hot I wanna go with it, I told him Alpina have used a 268 degree camshaft in their engine which was my reference. Since I didn't wanna push it too far I decided to go with a Schrick 272 cam, he nodded approvingly. Valve springs? Also Schrick, slightly tighter than the regulars, my goal was a head that was bullet proof up to 7500rpm. Regular redline is at 6.500 and anything over 7500 is overkill anyway. "You're gonna need new valve stem seals, that's no problem." he said. "What about the valves you want me to prop up your old ones?".

I'm telling you guys in a moment like that you literally feel like you're standing in some garage at Le Mans planning you're next race engine. It was an incredible feeling and for the first time I realized what that sparkle in people's eyes is about when they tell you 'I built it'.

Back to the dimly lit shop way out in the countryside with two guys looking at me with a mix of disbelief and excitement. "Valves will be new Schrick ones all around." I later found out that original valves are perfectly fine and rarely fail but wanted to make sure everything is rock solid. He went on "Rocker arms, planning to take the regulars?". Good question as these parts tend to break which can have grave consequences so I asked if there's an alternative. "Race parts" he said "close to 800EUR for a complete set". Mind you the standards can be had for 200 bucks - all of them. I put it down on my to do list.

## Compression ##

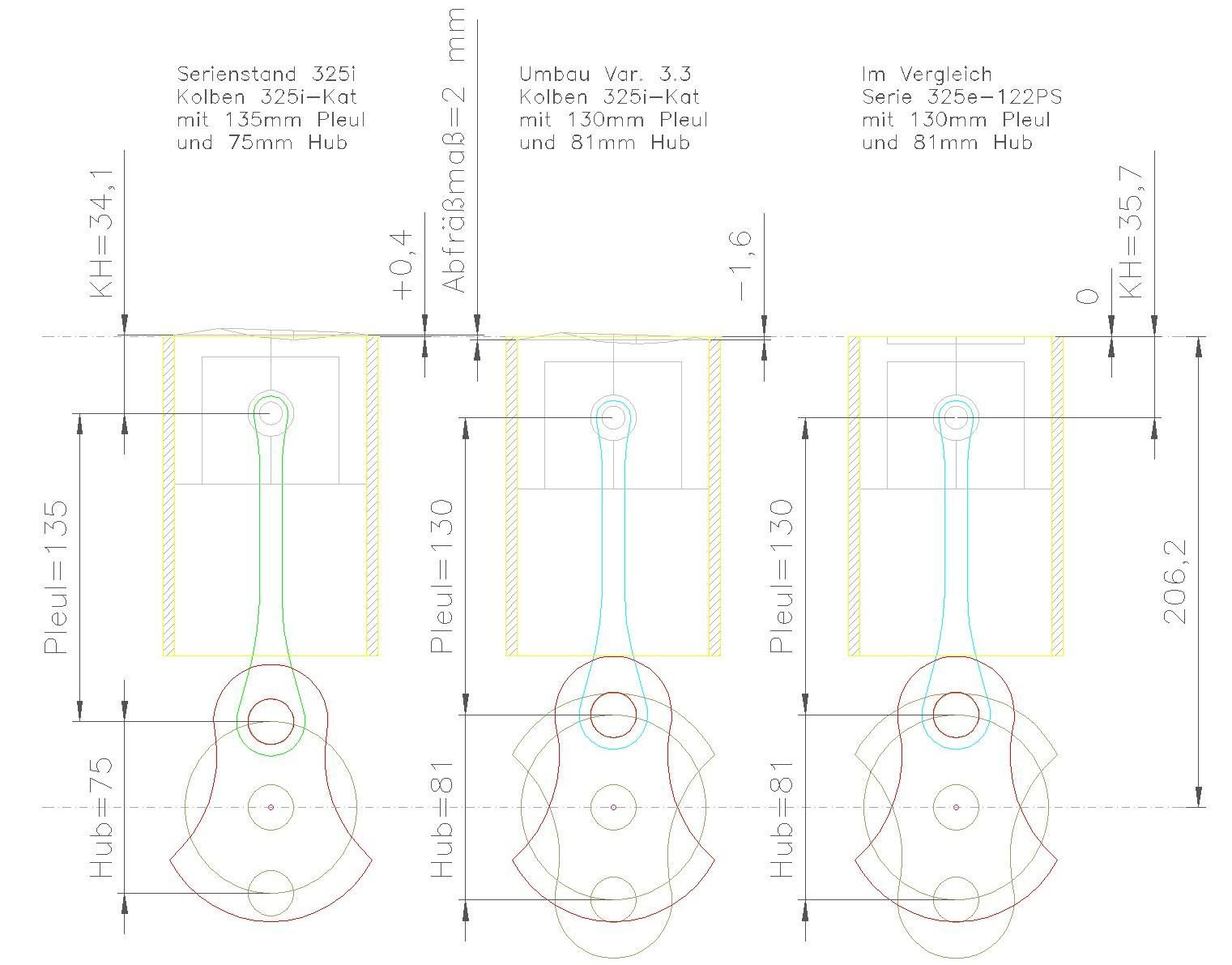

(Picture courtesy of www.e30.de)

See the way you increase the displacement here is by increasing the stroke which is achieved by using the crankshaft and piston rods from the M20B27 eta engine. In order to get to high compression though you must use the pistons from the original 325i engine.

On the left you see the regular 325i with a crankshaft with 75mm stroke and on the right the 'eta' one with 81mm stroke, that's the crankshaft we want. As we've seen before the 325e is a low compression motor so when combining that block with the 325i head and pistons we have to offset the low compression by bringing the chamber closer to the piston. This is achieved by decking the cylinder head i.e. milling off some material.

The problem is that the regular 325i piston skirt collides with the 'eta' crankshaft weights. Alpina have used specially produced MAHLE pistons to solve this problem (thousands of dollars again). Cutting the existing piston skirt on the other hand creates the issue of having to balance the pistons later on - something I wanted to avoid. Early 325i versions without a catalytic converter had pistons that would fit, so called 'catless pistons'. But they're just about as rare as the Alpina ones and equally expensive.

In the end I settled for so called 'weight optimized' late 325i pistons which do fit and are a bit more common. I only had to buy two sets until I found one that wasn't damaged - welcome to the world of hunting for spare engine parts :).

"If you provide the pistons" he went on "I'll put the head and the block together, see how much I have to deck each and mill the valve pockets in the piston to create the necessary crushing gap for high compression." If you just didn't understand a single word of that - neither did I at the time.

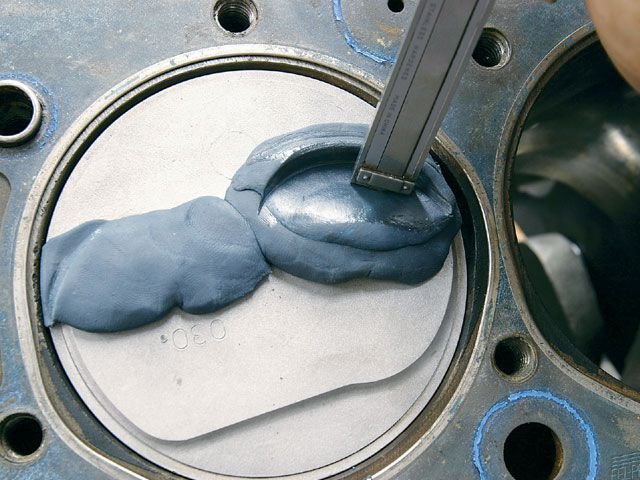

He's talking about this:

(Picture courtesy of GrumpysPerformanceGarage)

After decking the block and the head the motor has 2.7L displacement and a compression ratio of close to 10-1 but now the valves will collide with the piston as it moves to the dead center so what you do is measure how much it indents and then mill the valve pockets into the pistons accordingly. The way this is done you can see above.

So we were good to go and all I needed to do was bring him the head, the parts and the block and I'll get back my new engine...or something like that.

"What you're building here this is a beautiful motor, you won't regret it. Can't compare them engines to the planned obsolescence of today..." how right he was.

Headwork

After ordering some beautiful engine parts from Schrick and a wonderful BMW parts store in California called 'Ireland Engineering' I had it all together for the upper part:

Schrick 272deg symmetric camshaft, new valve springs and 12 shiny valves. Valve seats were standard BMW parts.

Check the difference here between the top and bottom shots, the milling and finishing qualities are vastly different. Imagine this thing ticking down on a valve several thousand times per minute...

The solution for the rocker arms came from the Cali guys. Above a nice comparison of a standard (truly terrible quality) part and their offering. Much more refined, strengthened and stable up to 8000rpm - I like! In addition to that they were even cheaper than the regular part and light years away from the 'race grade' parts.

Ireland Engineering adjustable cam-wheel. Because I changed the distance between camshaft and crankshaft by decking the parts this wheel helps to offset that difference by tightening the drivebelt.

In October 2012 the head was ready:

Shortly after all components were installed and it looked beautiful. Excuse the poor quality, didn't have my camera on me at the time:

So I had a rebuilt cylinder head, decked by 2.1mm to get a crushing gap of 0.8mm, an estimated compression of 9.9-1 and around 2.69L of displacement.

Just to give you an idea this is the cylinder head valvetrain after 247.000km:

This is the newly rebuilt one:

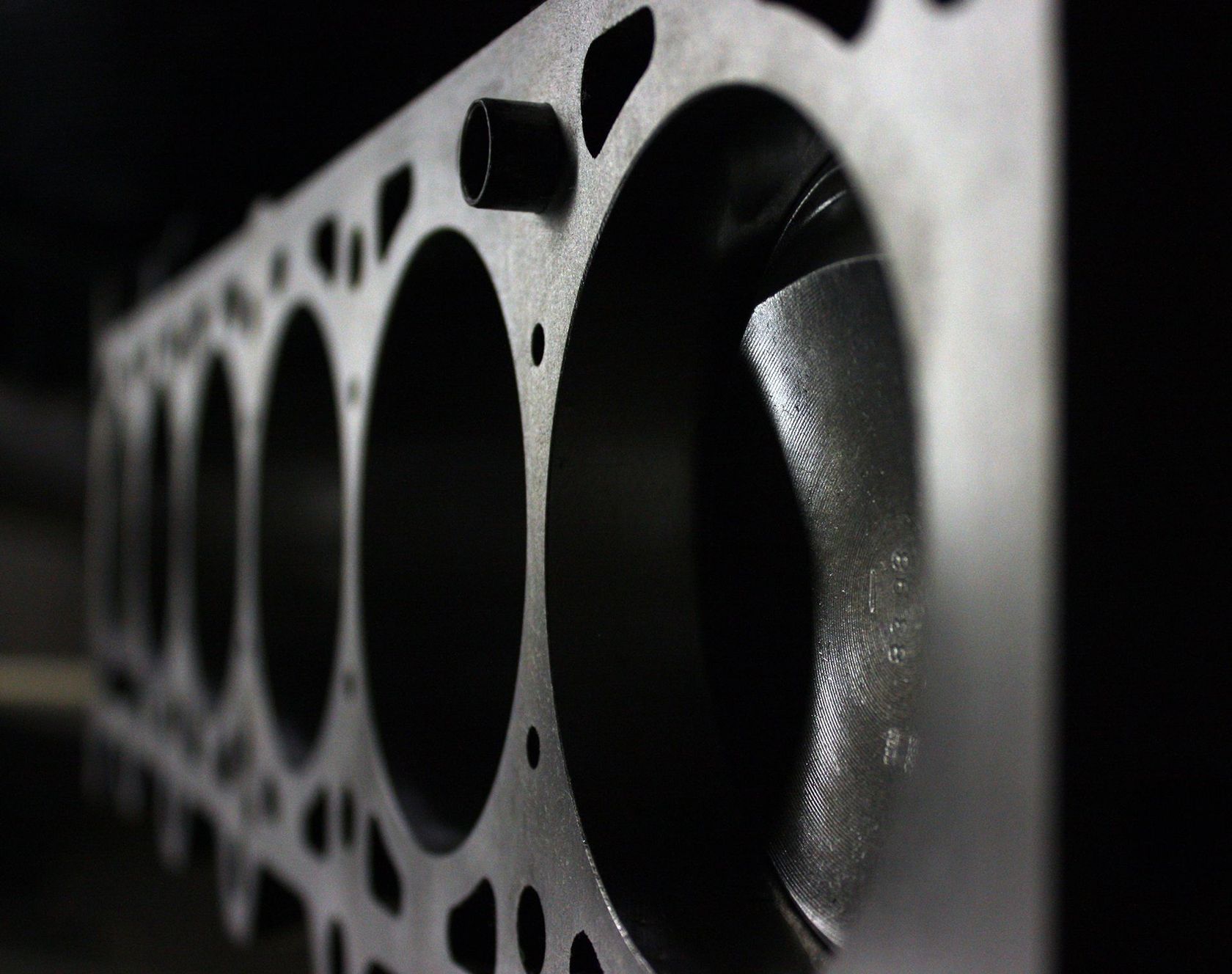

The Engine Block

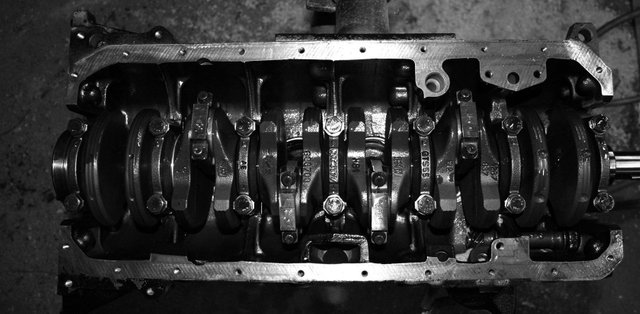

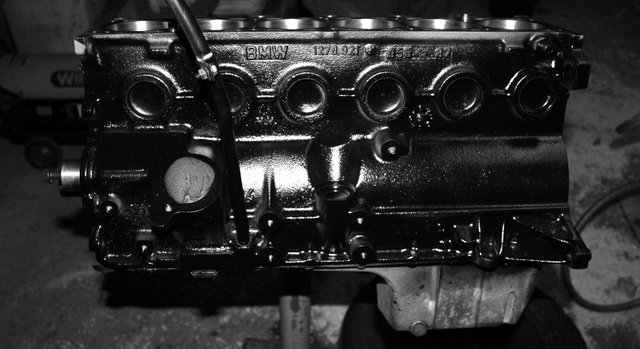

In January 2013 I got a call from Paul, the trusted engine builder, telling me the block is ready and that I'd really like the result. He didn't have to tell me that twice so I went to the shop and was awestruck by the simple and puristic beauty of my engine block.

So there it is, firing order 1-5-3-6-2-4 easily remembered by an old BMW saying: 15's too young, 36's too old, 24 is just right.

He had taken the 2.7L M20B27 block, cleaned it, decked by 0.3mm (just barely milled to get the full surface), rebalanced the crankshaft, put the original piston rods combined with the 'low-sideskirt' M20B25 pistons on it, replaced all bearings and installed everything with the specially ordered MAHLE piston rings into it.

I had it painted in plain black, lesson learned here as I later realized if you do this have your guy paint the block in matte black, that way coolant and especially oil leaks can be recognized more easily later on!

In any case the brand new engine slowly came together:

Assembly

In March 2013 it was time to put it together. Once this step is taken there's not much left to do:

Move the camshaft into a 'zero position' meaning valve-train needs to be in dead center position (more on that below)

Move crankshaft into dead center position

When both are set, the drive belt is put on the motor and the adjustable cam wheel is used to compensate for the amount head and blocked were decked thereby decreasing the distance between crank and cam

Following that valves need to be adjusted and the oil-pan is mounted, here you can see the opening for the oil level sensor by Hella which was standard on all cylinder E30s.

Now moving the crankshaft to dead center is easy because the crank and the block both have an indentation which when aligned signals 'dead center'. When is the valve-train in dead center position? That's quite hard to tell here actually, you can't look inside the cylinder and there is no certain way of telling visually.

However, the geniuses at SCHRICK have put a small flag on their camshaft which when pointing at 12 o'clock means 'dead center' position.

Took us about 2 hours to figure that out :). I said dead center and not valves closed position because SCHRICK also offers asymmetric camshafts with timings like 284/272 which means the valves are never fully closed. With these asymmetric camshafts the valve overlap is such that the valves themselves push and pull the combustion gas into and out of the chamber thereby sort of charging the combustion process which gives you extra bang. It also increases idle and does what all sharp cams do: more power on top, moving the torque curve to the end of the spectrum and robbing the lower rpms of most of their power. Since I didn't want that I settled for the symmetric 272 degree cam, 4 degrees more than the ALPINA 268 the reference engine uses.

Anyway having it all assembled and adjusted the camwheel could be used to tighten the drivebelt and connect the shafts at the correct timings, in my case adjustment was 0.2mm.

Remaining core parts followed:

Intake, oil pan, head cover, transmission and the so called 'shorty headers' - more on those later. Let's just say they're not headers as in pipe length is not equal. The only thing they facilitated in the end is to help cool the cylinder head by escaping the exhaust more quickly and, more importantly, separately out of the chamber. The regular M20 exhaust manifold collects the exhaust in a chamber which then goes into the pipe to the cat. This results in an increase in temperature along the cylinder head wall where the exhaust gases escape which could be one of the reasons for the many head failures along the wall between the 5th and 6th cylinder.

And one shot with the oily uncleaned transmission mounted:

The Exhaust

As for the exhaust system it had to facilitate good outflow, without too much resistance and most importantly fitting inbetween the headers' X-pipe and the muffler which I chose to leave stock M20B25 - in this case it's a BOSAL one.

The first choice fell on a standard M20B25 BMW catalytic converter. Well it was worth a shot shall we say as it didn't fit AT ALL.

Looks alright you might say. Well, yeah only that the front was a complete misfit with the x-pipe:

See here:

No welding in the world is going to make that work. Thing why I opted for the stock cat in the first place was that it would facilitate a near stock exhaust system combined with headers. At this point I realized that won't happen. There is no way to alter the header/x-pipe location at all and so there had to be a compact cat solution that fits under the car and has roughly equal pipe diameters from front to back.

I went out to hunt for a good cat and bought some stainless steel exhaust pipes with a diameter of around 55mm.

For now this was my exhaust setup:

200 Cells and Stainless Steel Welding

I soon found a guy who had a similar setup and the same problem. He had bought a 200 cell metallic catalytic converter from a company in Berlin called Unifit. They offer 200 and 400 cell cats. Basically the lower the number of cells the more throughput you have in terms of exhaust gas flow so less resistance while at the same time having a relatively high degree of conversion AKA less toxic exhaust. It fit perfectly once assembled:

Pretty much all third party 2x50mm 200 cell metal cats come out of the same factory in China which at the time of my order had serious supply issues and the delivery time went from long to 'we don't know when'. So I bought a used one and had it delivered it to my mechanic.

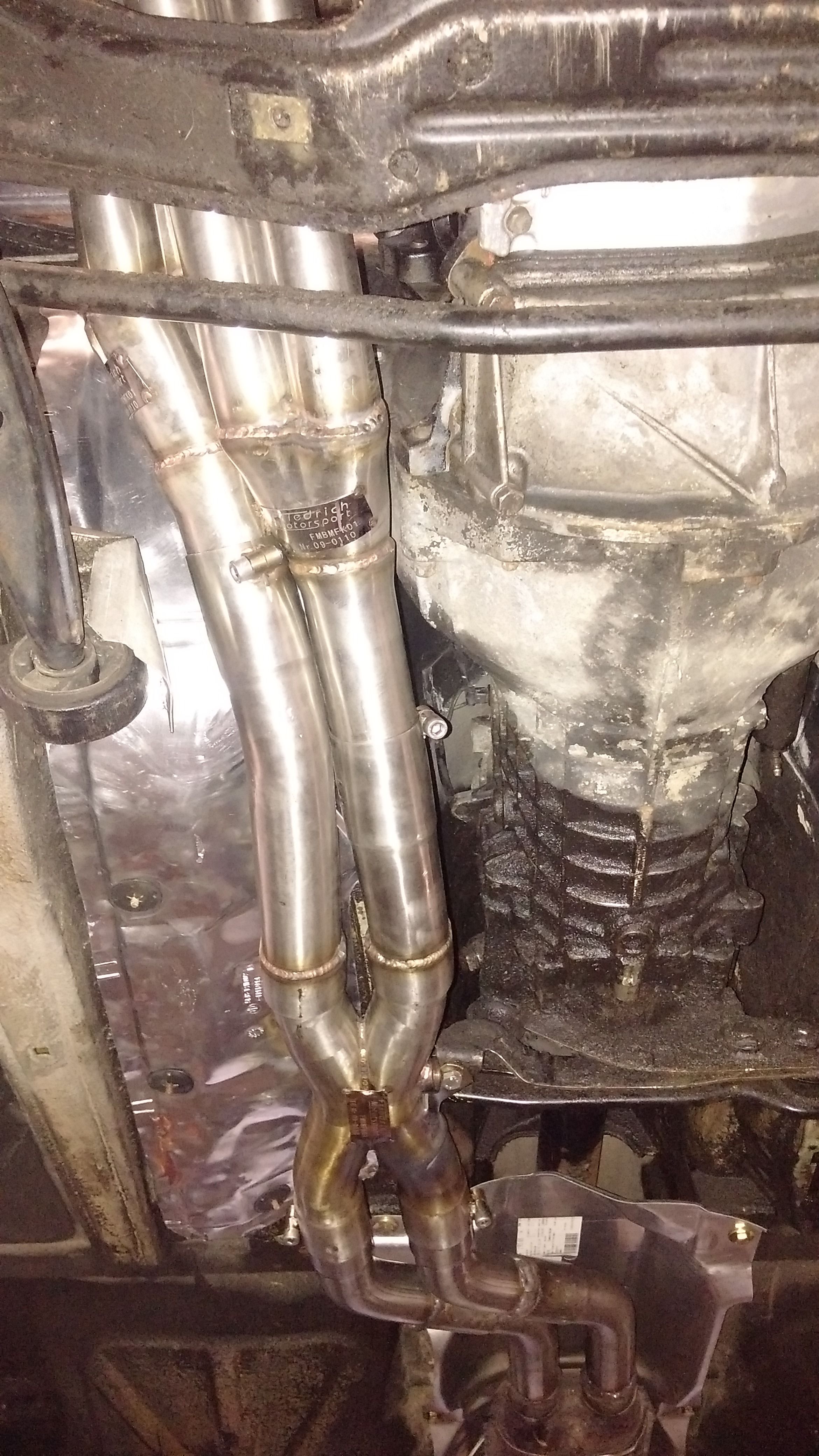

The system is entirely customized and basically goes like this:

cylinder head > headers > 3 to 2 to 1 > dual pipe cat > dual pipe muffler all within around 50mm pipe diameter

The X-pipe had mounting screws so no welding was required. The connecting pipes were welded to the cat and from the cat to the muffler so everything after the X-pipe is one piece. Stainless steel up to the muffler and then stock muffler to the end.

The welder is a specialized guy who welds stainless steel like you wouldn't believe, check out the accuracy:

The metal cat had some advantages, first of all it built very low and fit extremely well into the stock exhaust tunnel. Second it delivered exceptional emission values in testing and third it had a beautiful sound and aided the engine's performance. There is little clearance to the engine mounts, transmission mount and rear axle but it all moves freely and there is no contact anywhere:

The muffler was adjusted to sit with the pipes in stock position before we aligned it to the cat pipes, in the end the system came out almost 100% straight. The X-pipe actually is screwed onto the transmission mount in the original stock position.

The lambda node cable had to be extended, it is fully functional and the car exceeds the Euro 2 emission standards it's more like Euro 3 which is almost California compatible.

The only 'downside' if you can call it that is that it is quite loud with a metallic, race car type sound when revving above 3000rpms. Basically the engine's valve train in combination with the headers and cat generate a very nice but also very flat and metallic sound which requires a bass heavy and deep note after market muffler to arrive at the classic BMW straight 6 sound. Currently with this setup all you here is the headers and cat and the muffler is basically non existent. I'll have to find a nice stainless steel after market muffler and weld that onto the cat pipes in the future.

Core Parts

Anyway this is the story of the entire drivetrain. In summary:

~2.7L R6 2 valve M20 engine

Alpina B3 2.7 ECU mapping in standard M20B25 DME

NGK ZGA5R spark plugs

Liqui Moly 15W-40 engine oil

BMW M20B25 pistons with shortened piston skirt

BMW M20B27 (129hp) crankshaft

Schrick 272 degree camshaft

Schrick Valves (slightly larger diameter)

Schrick valve springs (slightly stronger than stock)

BMW valve seats and valve stem sealings

Ireland Engineering camwheel

Ireland Engineering heavy duty rocker arms

Friedrich Motorsport exhaust headers and x-pipe (lambda node installed)

Unifit 200 cell metall catalytic converter (2 x 50mm)

Stock M20B25 exhaust muffler (2 x 60mm)

Intake valves adjusted to 0.30mm

Outlet valves adjusted to 0.35mm

M20B25 intake system

Standard M20B25 5-speed manual transmission

BMW 3.73 25% locking differential

Cooling system consists of 'desert version' 324td extra large radiator with extended water hose and regular water pump

The diff is quite short given the power and relatively high low end torque so acceleration is outstanding, probably comparable or slightly quicker than the Alpina B3 2.7. At 5500rpms the car goes 125mph, at 6000rpms it reaches 140mph with around 500-600 left to go which it has no issues going into. Maybe I'll throw in a slightly longer diff at some point to make longer journeys a bit quieter. The alternative would be an E46 320d 6-speed manual with a shortened driveshaft which would enable a cruising speed of around 120mph at below 3500rpms :).

The cooling system keeps the engine at 12 o'clock even in 35 degree, high summer, traffic jam idle over prolonged periods of time.

Anyways hope you like this special one off engine only post.

Feel free to leave questions and comments!

Oh man, reading the comments I just noticed how long this entry is, went a bit overboard I guess. But hey this is all there is to say about the engine :).

Awesome ! 7 years lots of time and at the end you success.

This Post was Added to the Steemit Social Media Queue.

WEI HONG CHUANG Electronics Co., Ltd. (SOPSMT), which specializes in SMT machines and spare parts. SOPSMT has more than 10 years of experience in the electronics processing equipment industry. Customers all over the world, and win the trust and praise of customers. Long-term customers include BOSCH and FLEX in Spain and India, , Panasonic in Mexico, Samsung and Cliptechin Brazil.

no turbo?